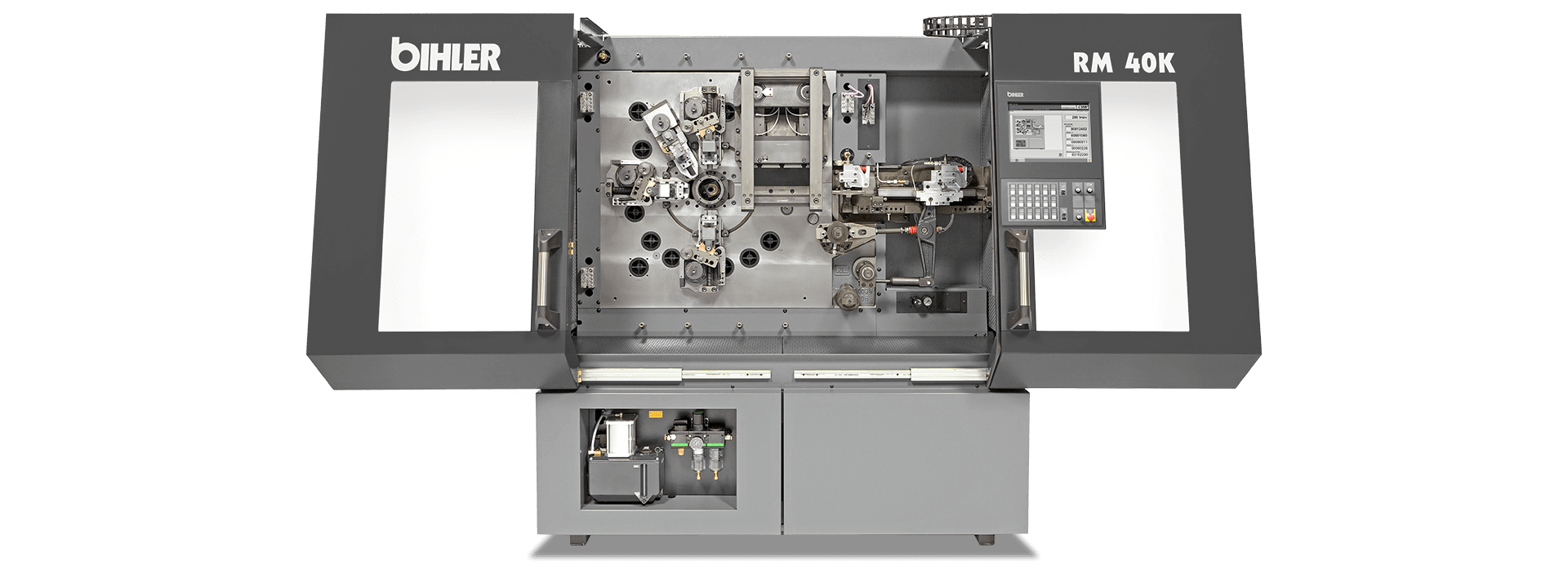

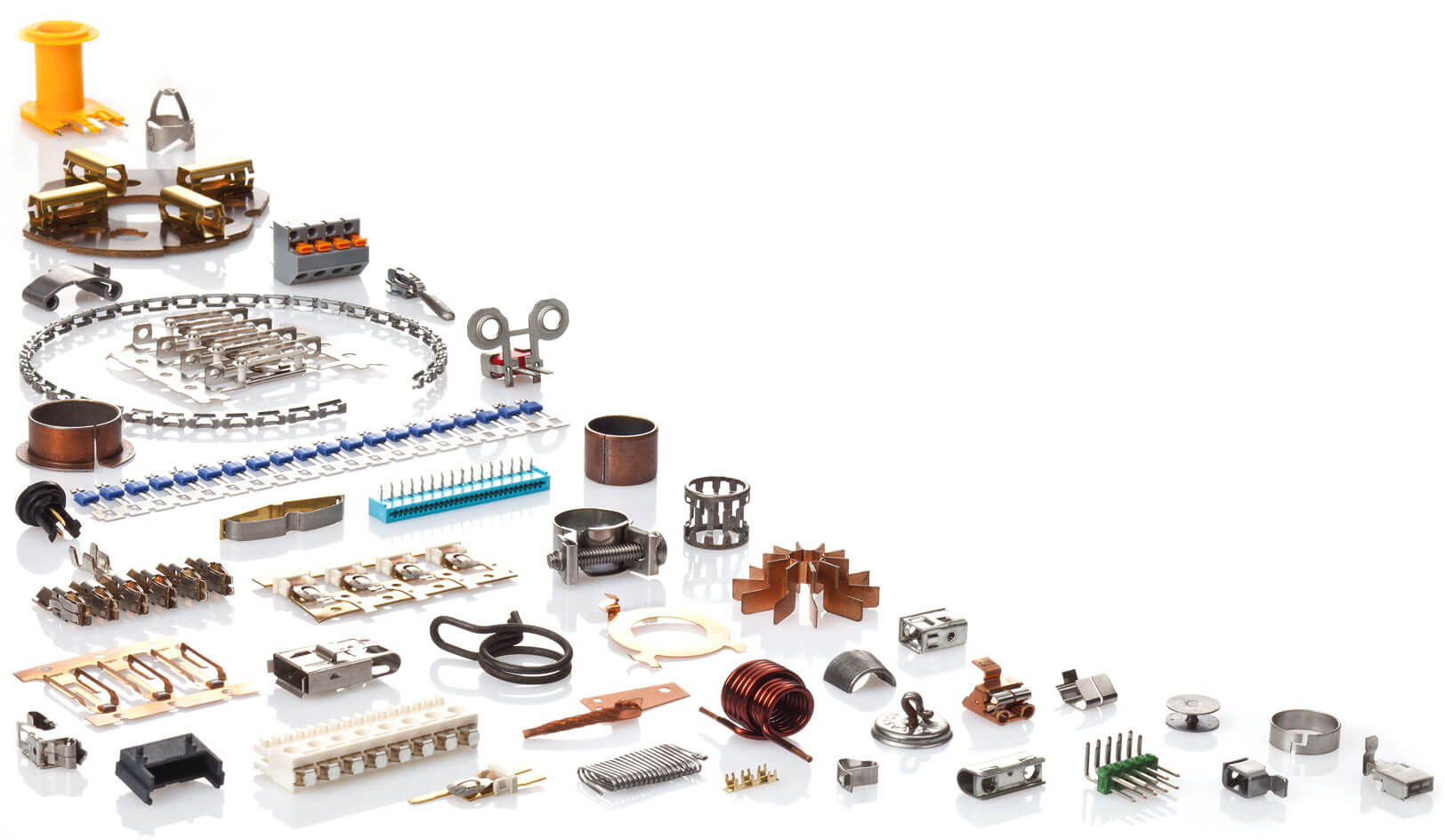

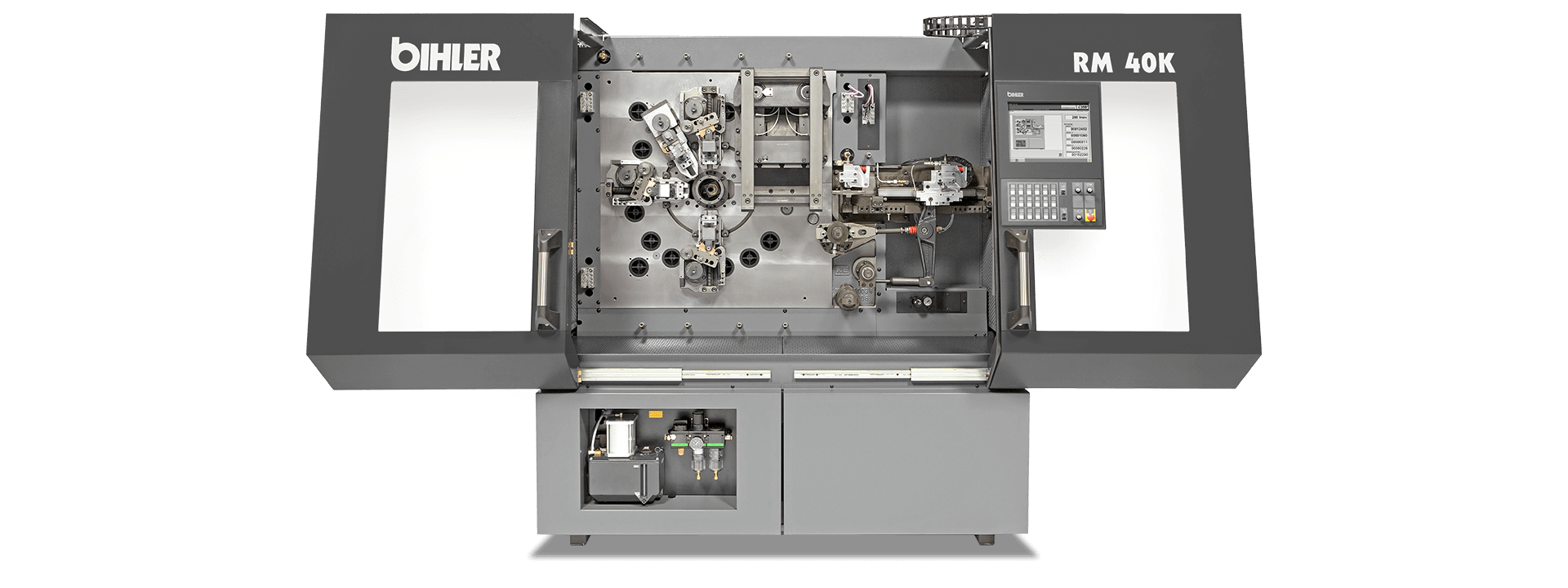

Compact, powerful machine system for mass production of small stamped and formed precision parts

- High production speeds up to 350 1/min.

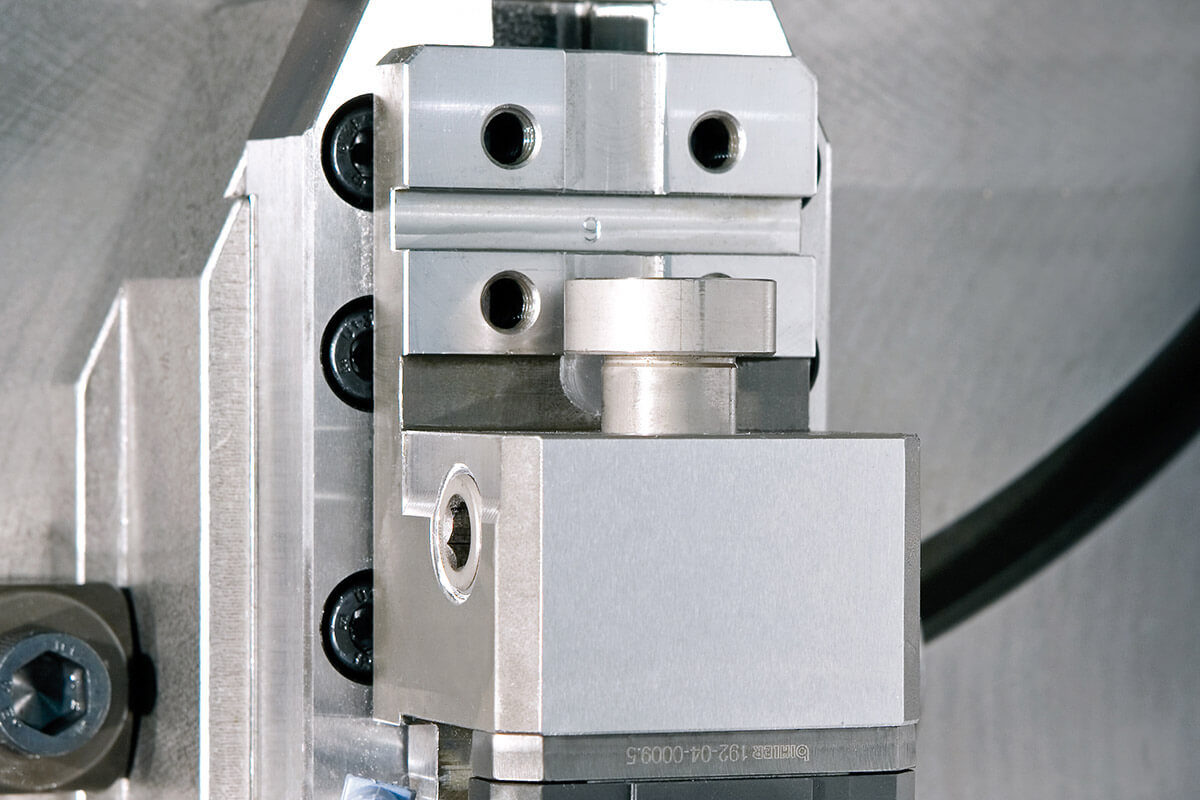

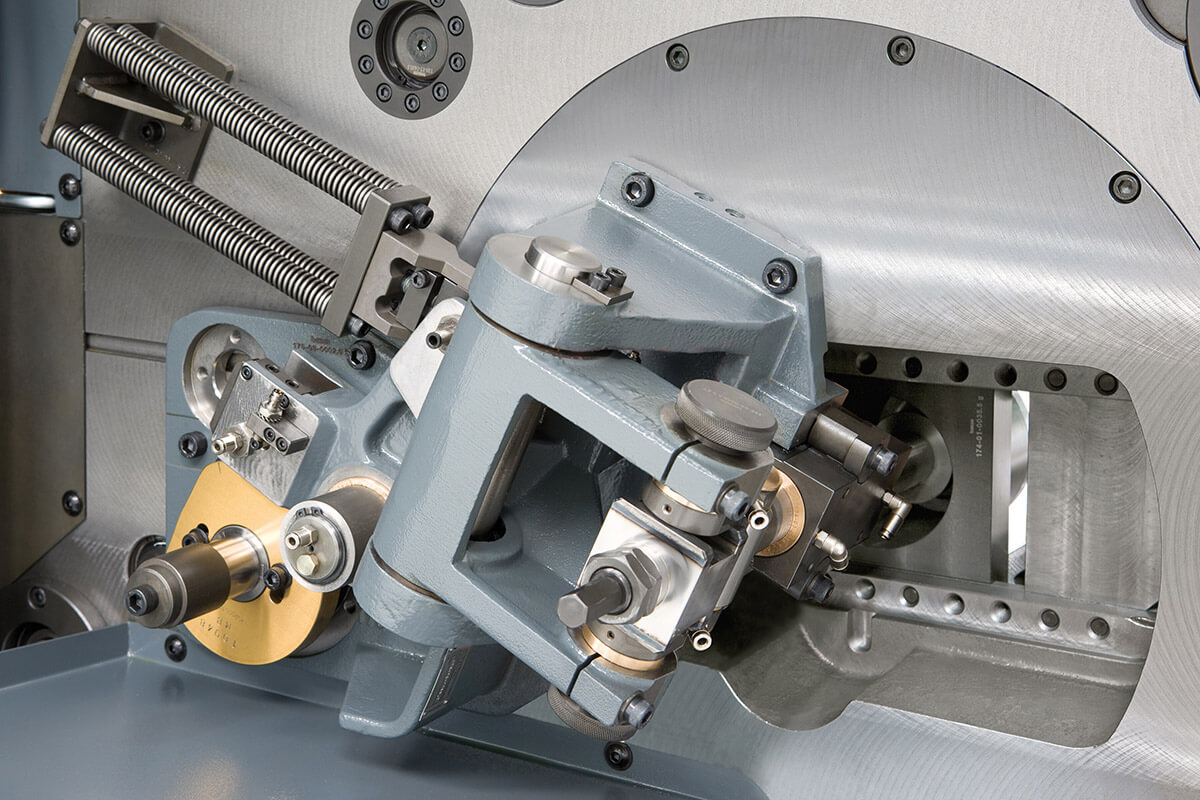

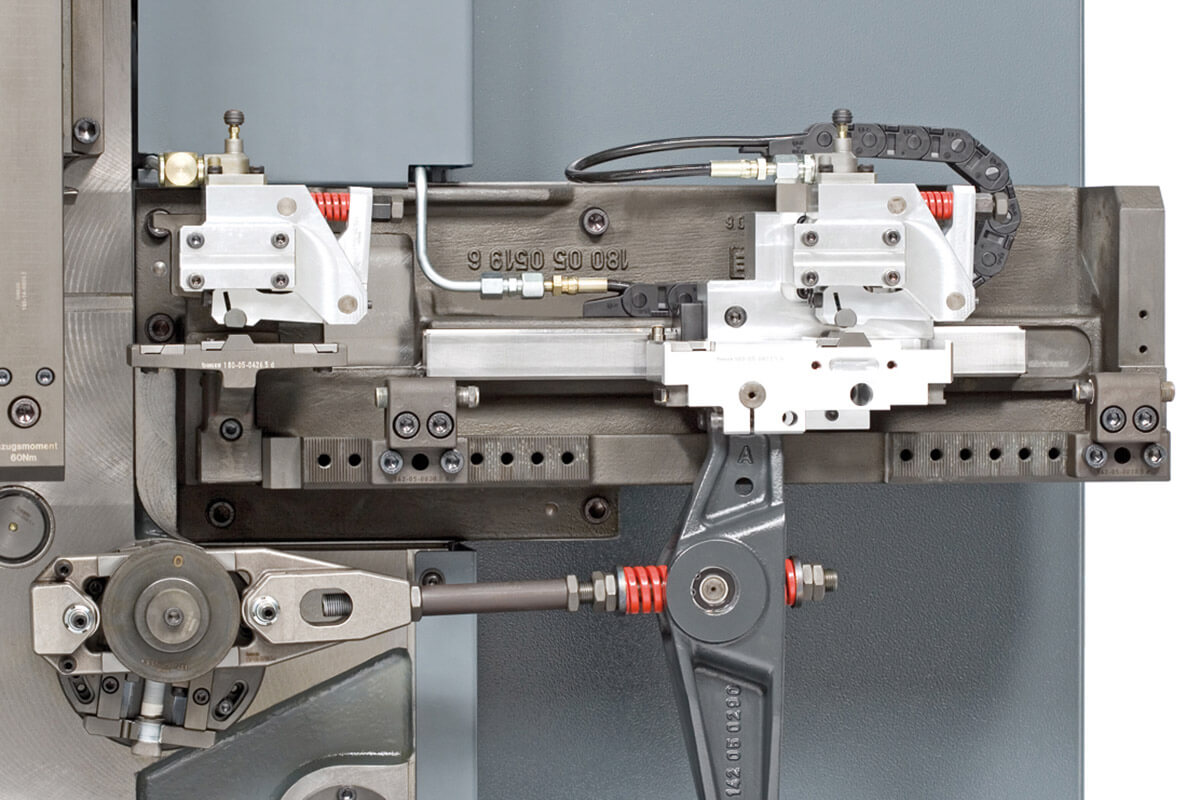

- Perfectly designed for radial and linear tooling concepts

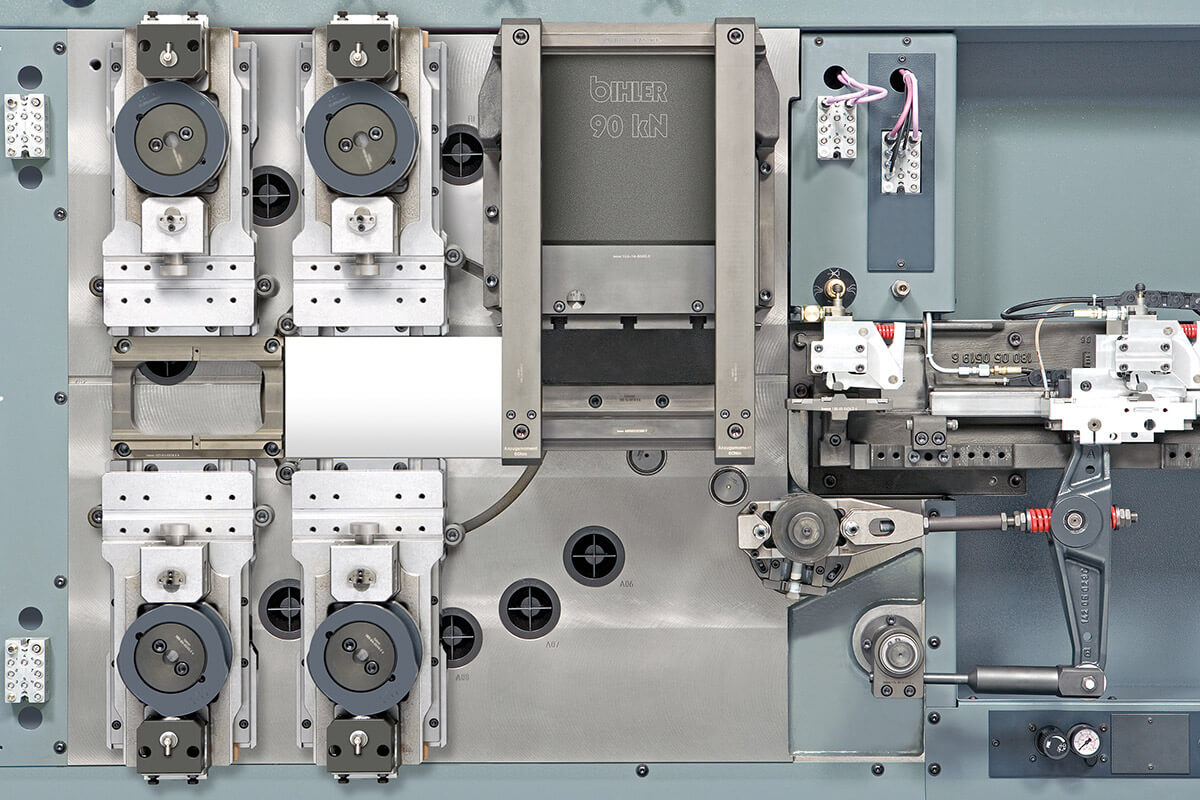

- Rigid 90 kN two-point eccentric press for precise cuttings

- Large center aperture in the work-plate for flexible central mandrel movements

- Rapid tool-exchange system for shortest changeover time

- User friendly VC 1E control with 15” touch screen

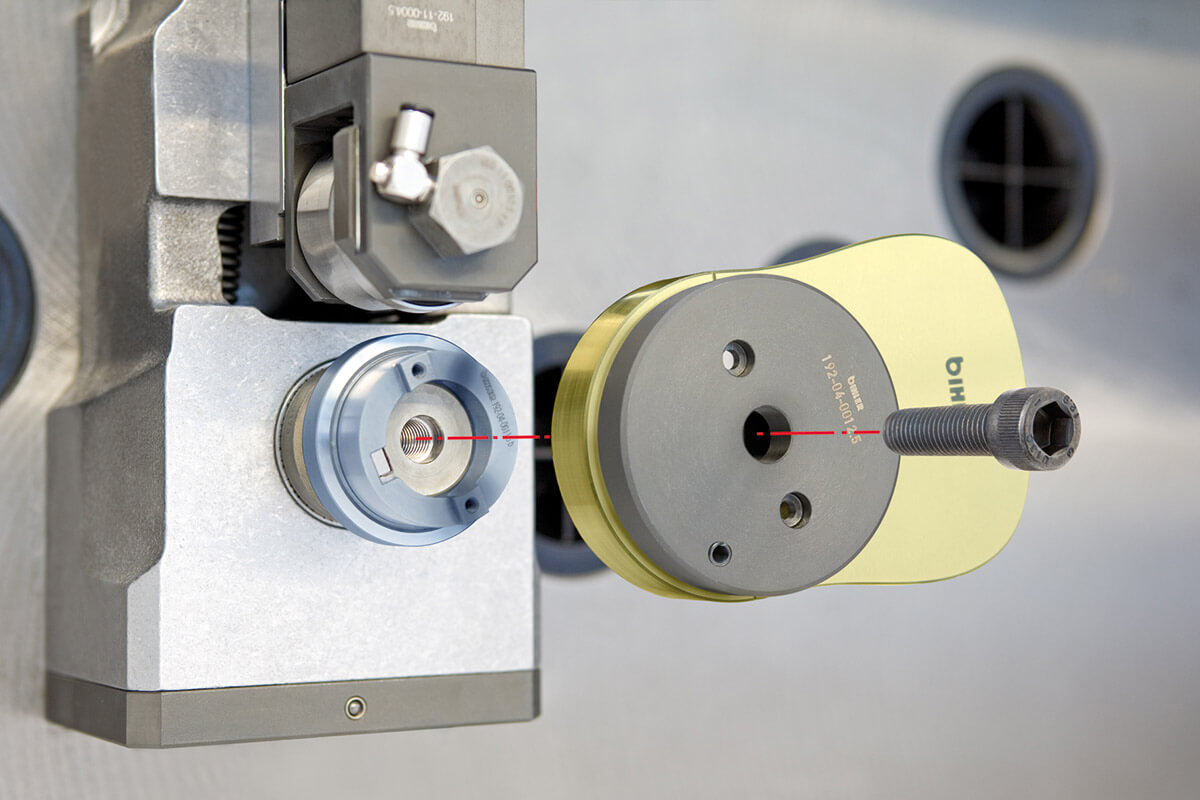

Production of “Winding elements”