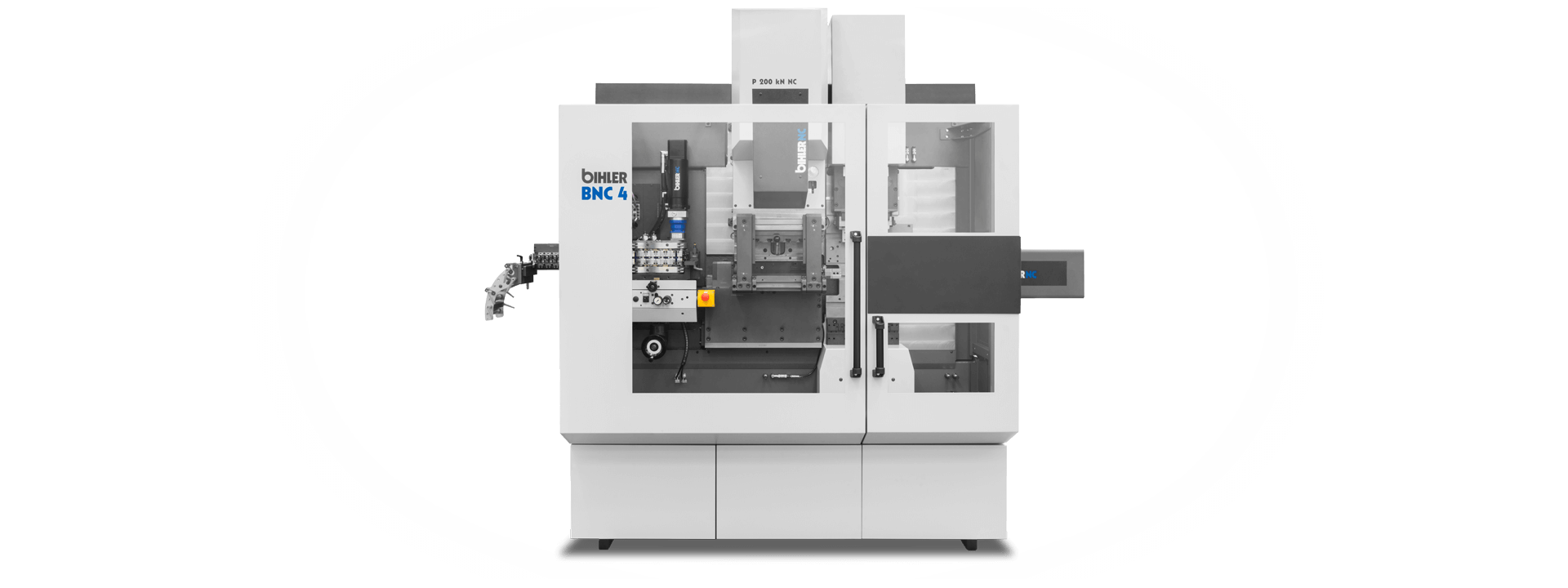

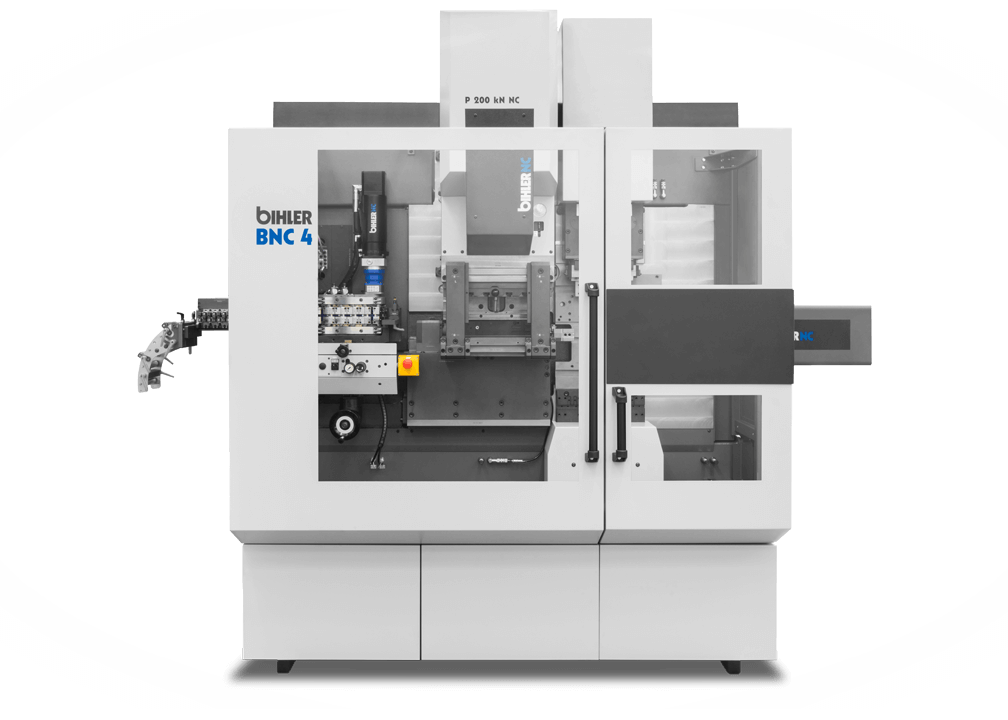

Standardized servo manufacturing system for a highly productive manufacture of classical stamped and formed parts

- Full tool compatibility with MRP machines (UB2, UB2B, UB3, UB3B, UB4, UB4B)

- Significant increase in output

- Easier and faster machine set-up

- Minimum tooling time

- Rapid response to short-term customer requests

- Maximum process safety and product quality