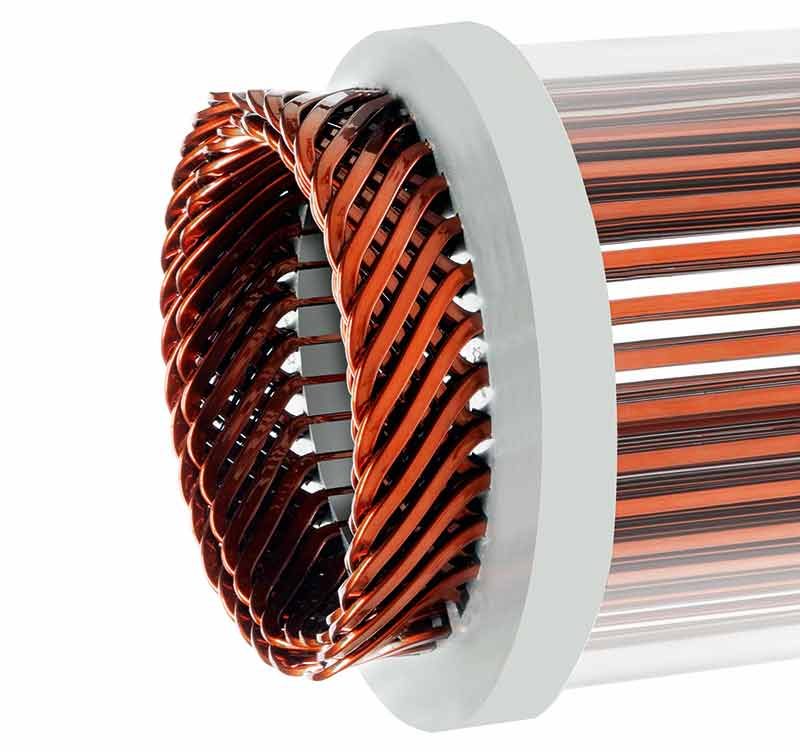

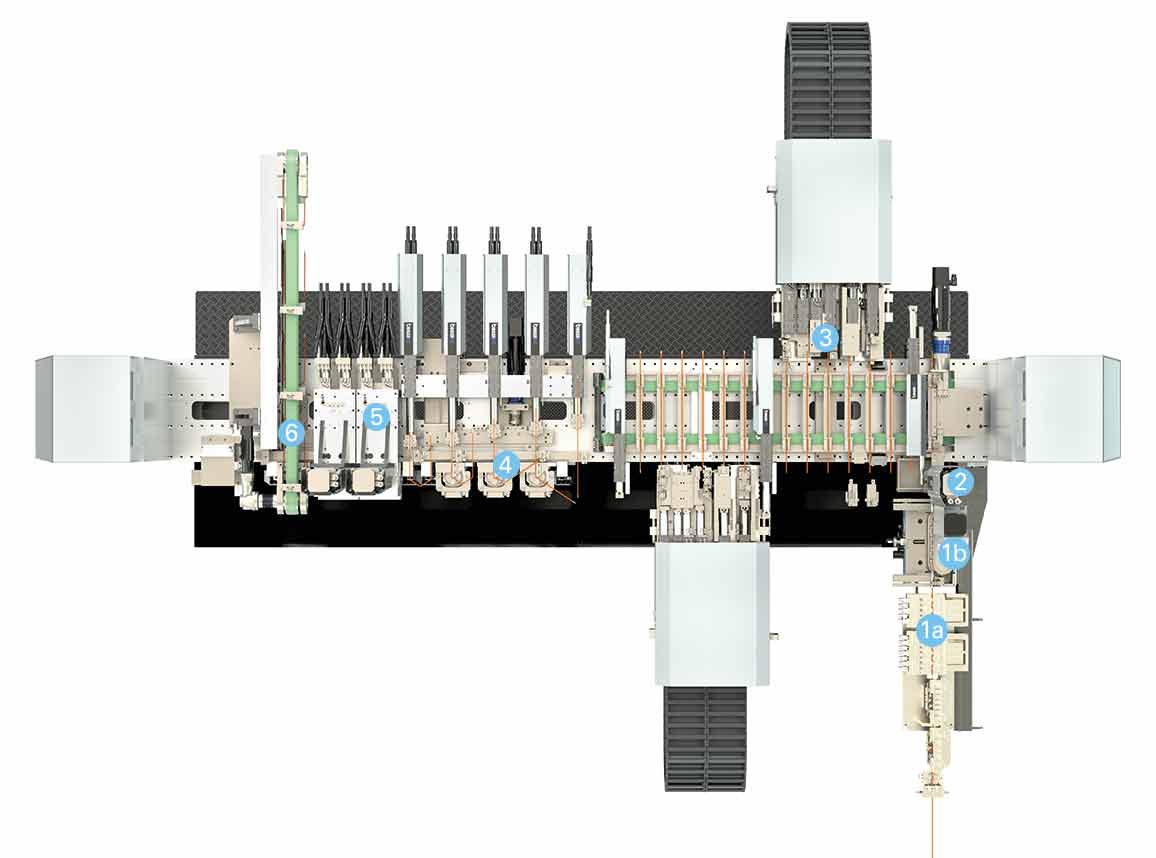

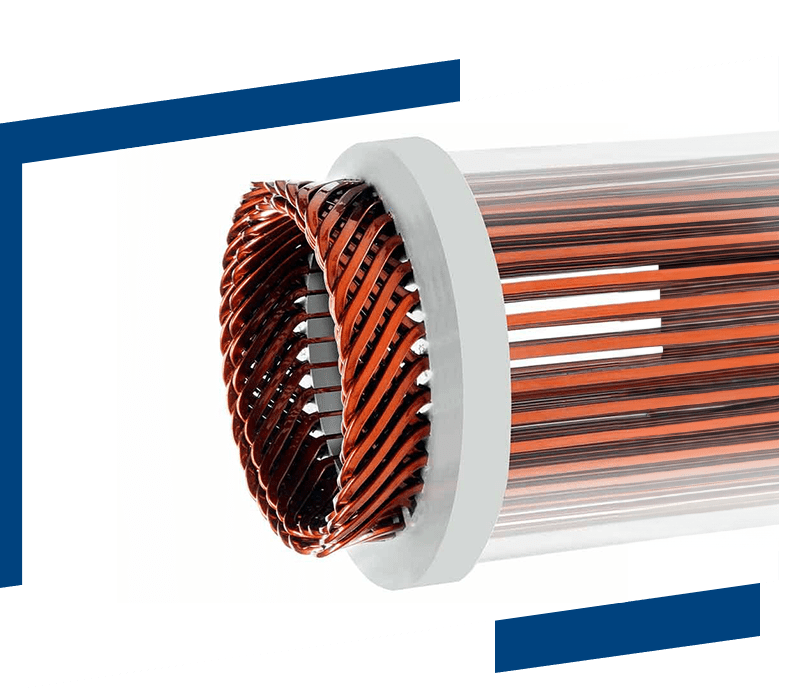

Efficient and Flexible Hairpin Production

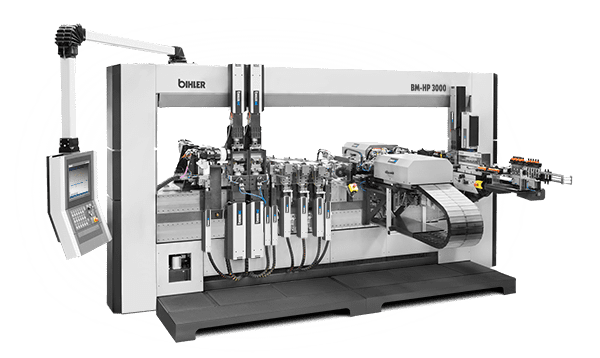

With over 40 years of expertise in hairpin technology, Bihler offers a cutting-edge solution for the industrial mass production of hairpins.

The BM-HP 3000 system streamlines every step of the process with standardized machining techniques; highly dynamic, slip-free wire feeding, precise cutting, NC-controlled mechanical stripping of coatings, simultaneous chamfering of pin ends, 2D pre-bending and 3D die-bending. The system seamlessly handles removal and mono-component storage, ensuring a smooth workflow from start to finish.

Achieve three times the cycle rates of sequential systems while enjoying quick, on-the-fly variant changes and consistently reliable production performance.

Machine Details

- All-in-one production of hairpins from flat wire directly off the coil

- Flexible, rapid change of variants “on the fly”

- High output: 60 – 120 finished hairpins per minute (depending on material cross-section and leg length)

- Cycle speeds are three times higher than with sequential systems

- All common hairpin geometries can be produced

- Predestined for industrial mass production

- 100 percent reproduced top quality of parts

- Additional machine and space requirements can be reduced

- Flexibly adaptable to future tasks

- Article in “b on top”: Efficient hairpin production

Modular Process Steps

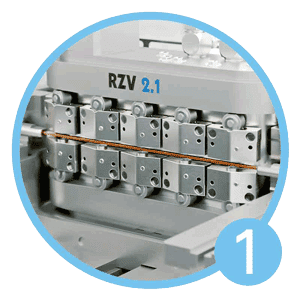

Wire Infeed After Multilevel Straightening

Wire Infeed After Multilevel Straightening

The precise straightening of the enameled copper wire (1b) contributes to the highly dynamic, slip-free infeed (1b) of up to a maximum of 3.2 m/sec. The repeat accuracy achieved during this process is +/- 0.02 millimeters.

Precise Cutting

Precise Cutting

The enameled copper wire is cut accurately and cleanly to its stretched length – in exactly the way required for subsequent processing.

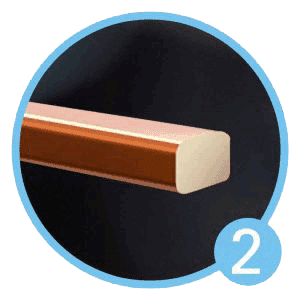

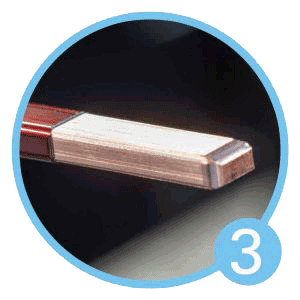

Isolation Removal and Chamfering of Pin-Ends

Isolation Removal and Chamfering of Pin-Ends

The automatic removal of the isolation and simultaneous chamfering of the two ends of the enameled copper wire are performed mechanically. During this process, the overall cross-sectional loss is less than 0.05 millimeters. In process: online measurements of copper core.

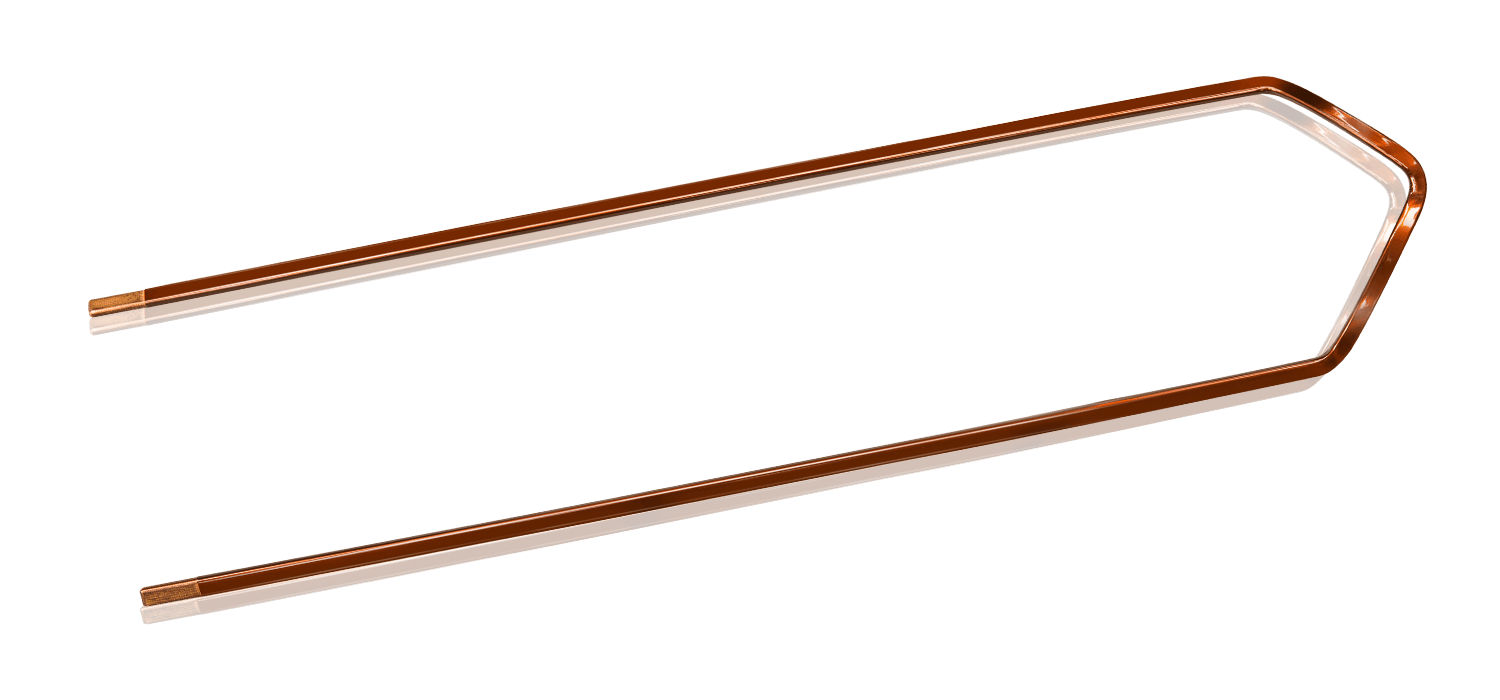

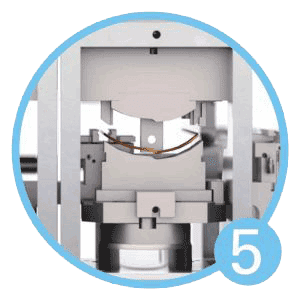

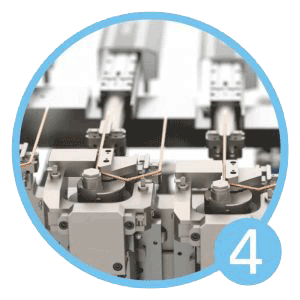

2D Preliminary Bending

2D Preliminary Bending

During 2D preliminary bending, powerful servo units for the fast, accurate execution of multi-step tool movements ensure the correct geometry values, which can be freely programmed if required.

Scalable, Compact Automation Solution

The BM-HP 3000 is based on the modular BIMERIC servo production system. It impresses with its high output of 60 to 120 finished parts per minute. Variant changes are particularly flexible: solely by calling up the stored data – at a constant machine cycle rate, without machine downtime and without worker intervention.

For future requirements, the hairpin machine can also be flexibly expanded with additional process modules or the arrangement of the modules can be adapted. The central VariControl VC 1 control system guarantees safe and simple operation of the machine and all processes. And complete production on one production system saves additional equipment and the space required for it.

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin