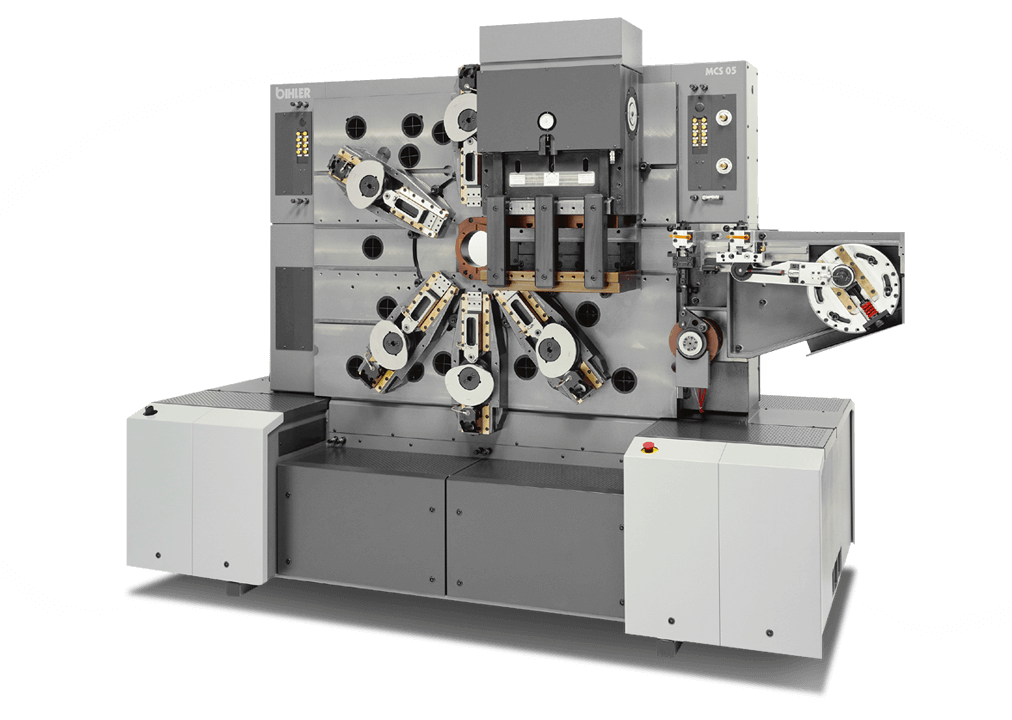

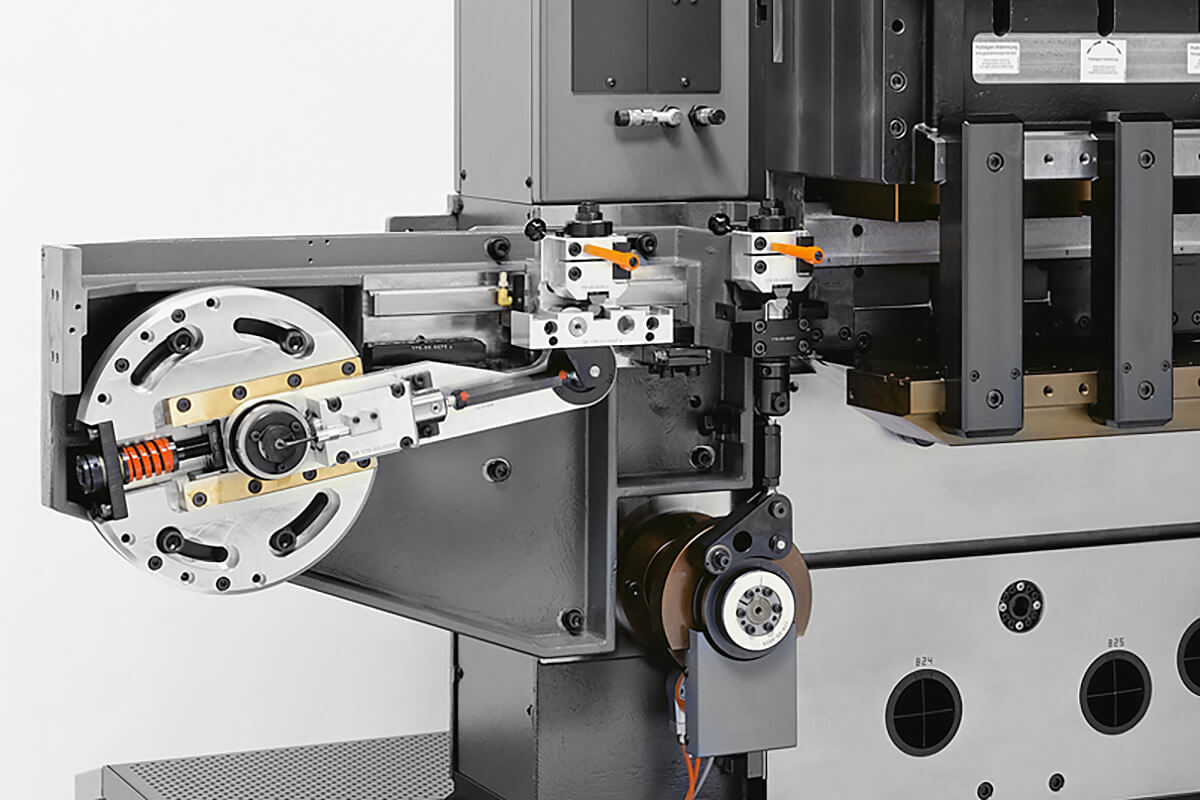

High-performance machine system with two processing faces for mass production of large stamped and formed parts and sub-assemblies

- Very high production speeds up to 500 1/min.

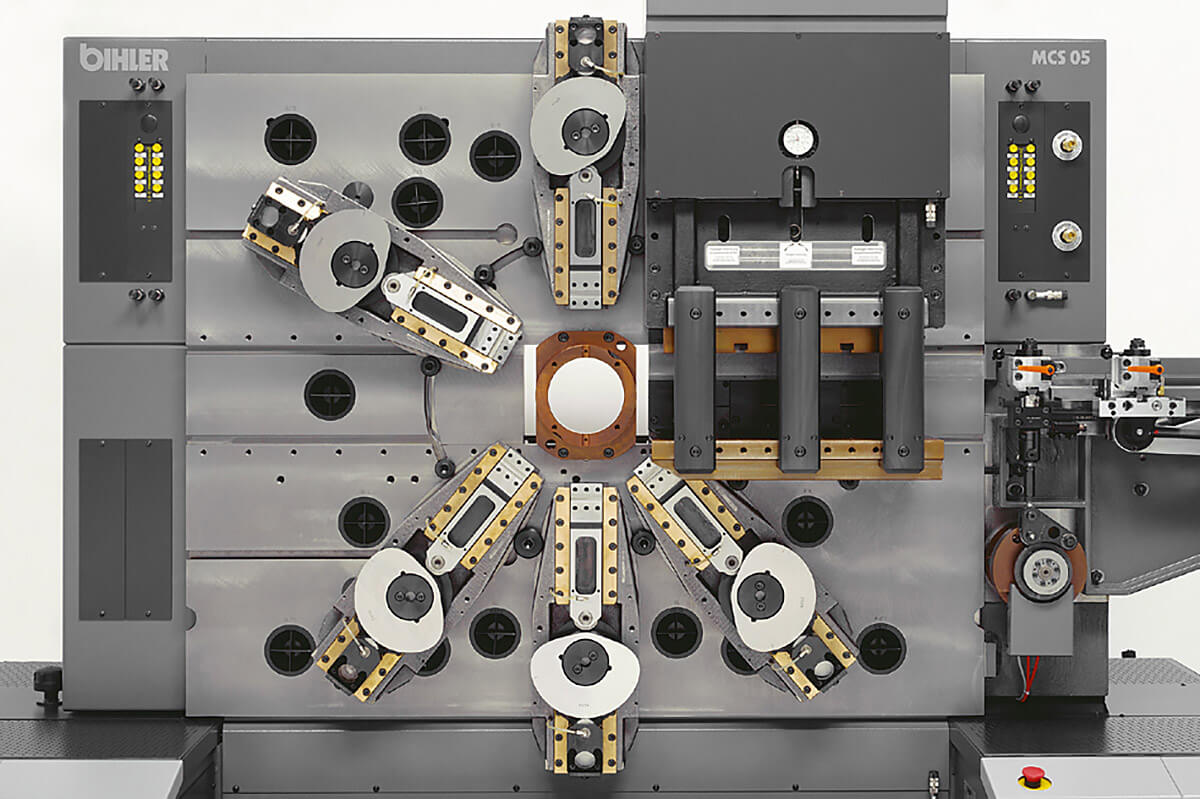

- Maximum economic efficiency through joint radial and linear production of parts and simple sub-assemblies on one same machine

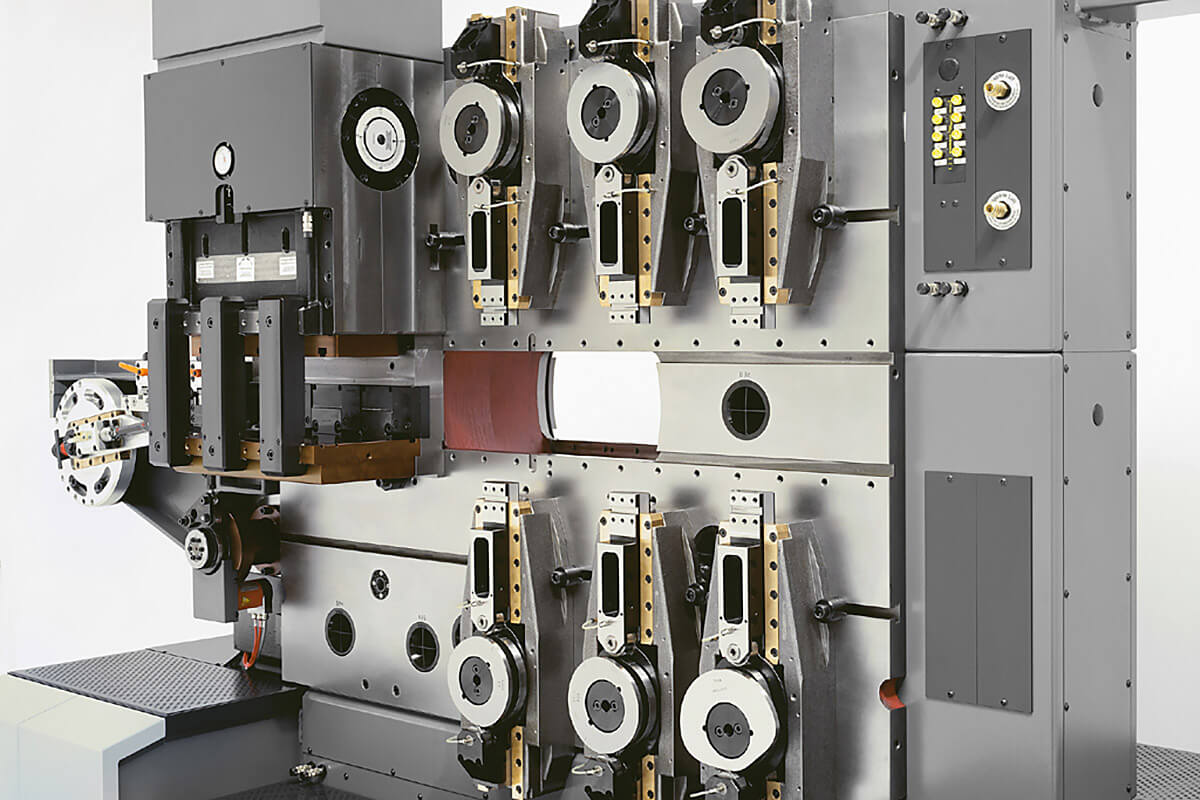

- High performance level of all standard modules and flexible system modules

- Highly dynamic material feeding unit for shortest feeding times

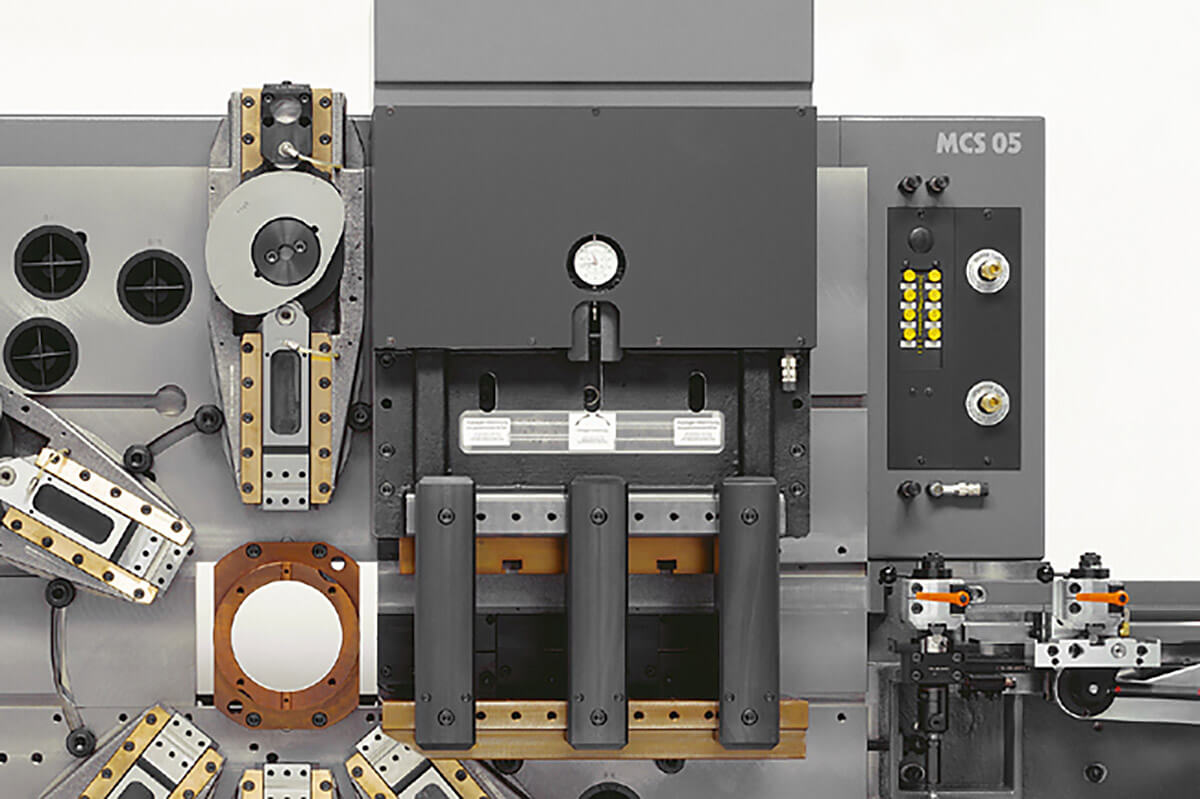

- Large opening in the center for transverse transport from face A to face B or vice versa

- Easy and secure operation with VariControl VC 1