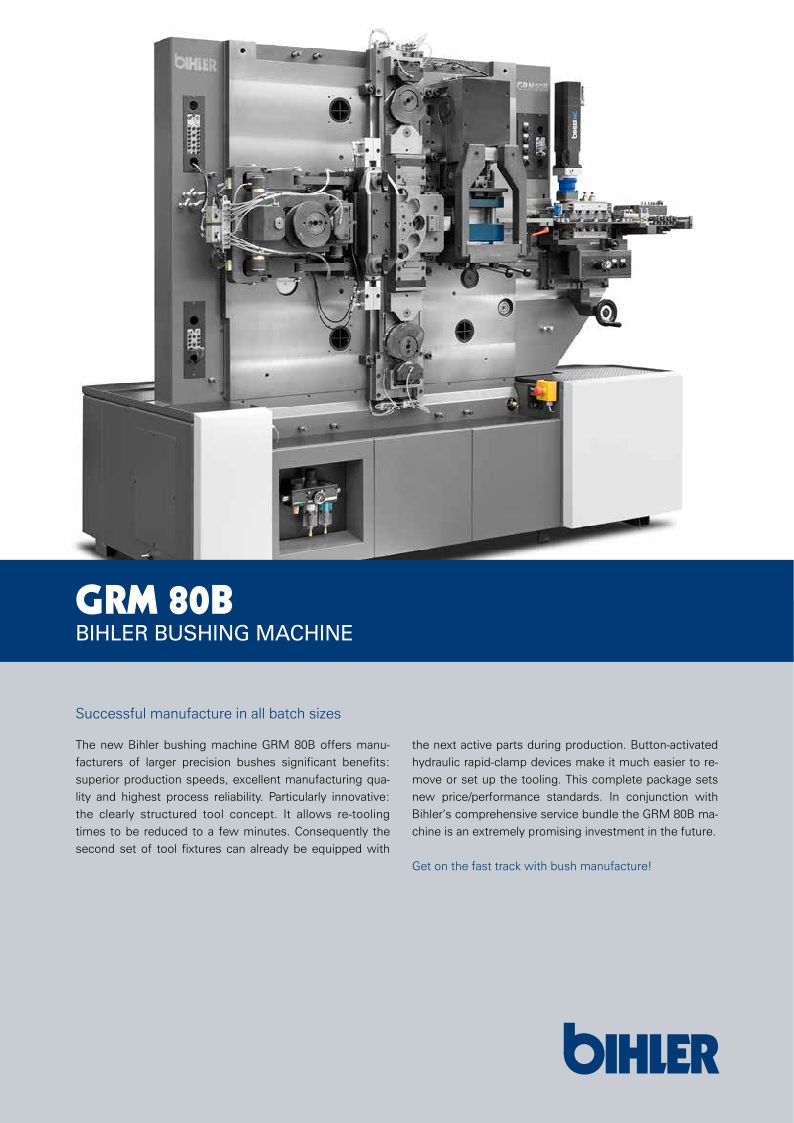

Successful Production for All Batch Sizes

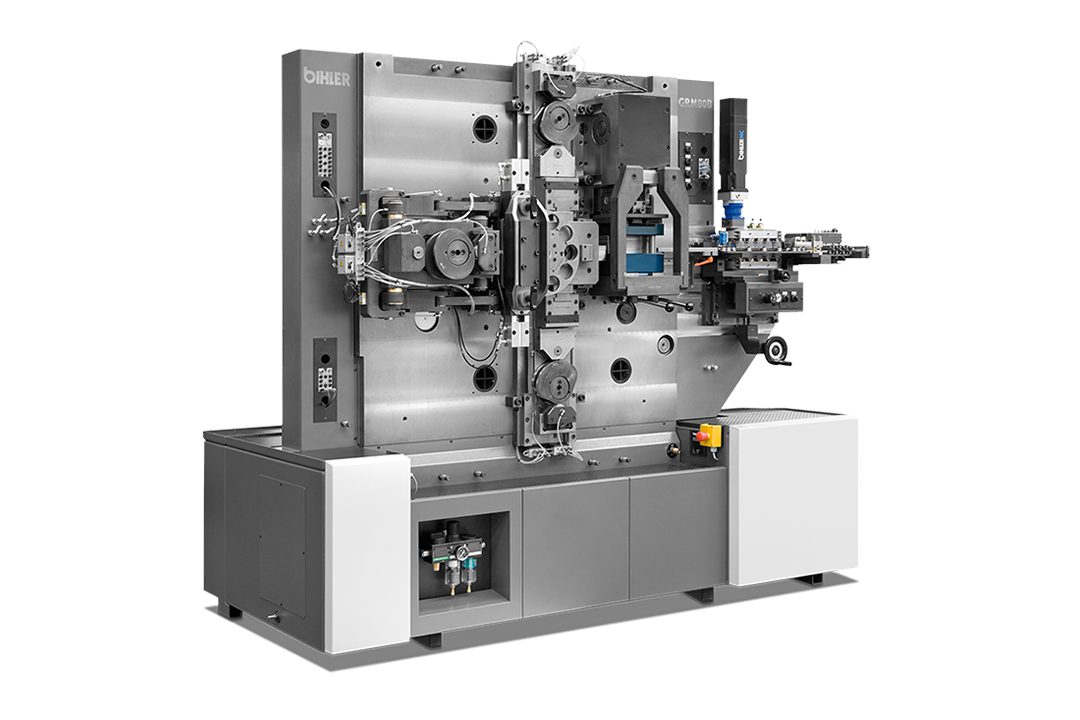

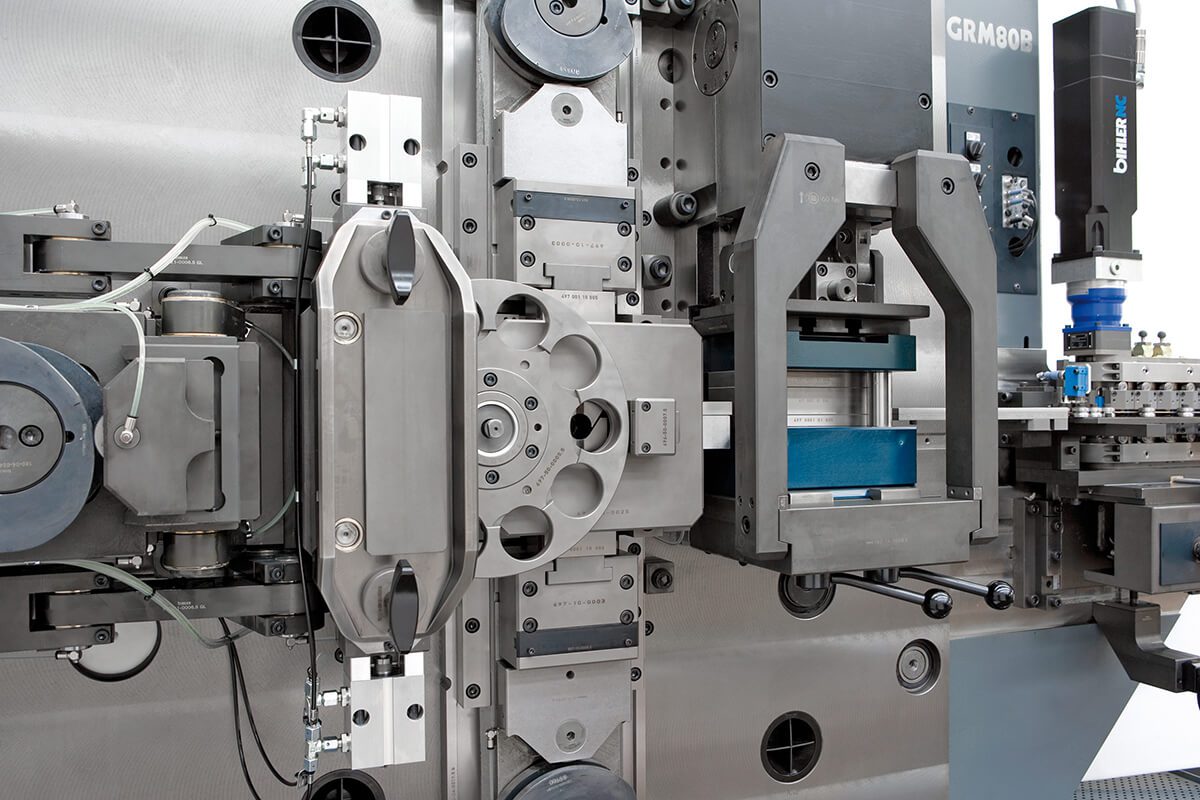

The new GRM 80B bushing multi-slide machine offers manufacturers of larger precision bushings significant advantages: superior production speeds, excellent manufacturing quality, and maximum process reliability. A particularly innovative feature is the clearly structured tool concept, which reduces setup times to just a few minutes. This allows the second tool holder set to be equipped with the next active parts during ongoing production.

Hydraulic quick-release clamps, activated at the push of a button, significantly simplify the assembly and disassembly of the tool. This complete package sets new benchmarks in terms of cost-effectiveness. Combined with Bihler’s extensive support offerings, the GRM 80B represents an excellent investment in the future.

Put your bushing production into the fast lane!

Machine Details

Standardized, powerful machining system for mass production of straight bushes and flanged bushes

- Standardized tooling concept (basic tooling, 2 sets of tooling fixtures, active tooling parts)

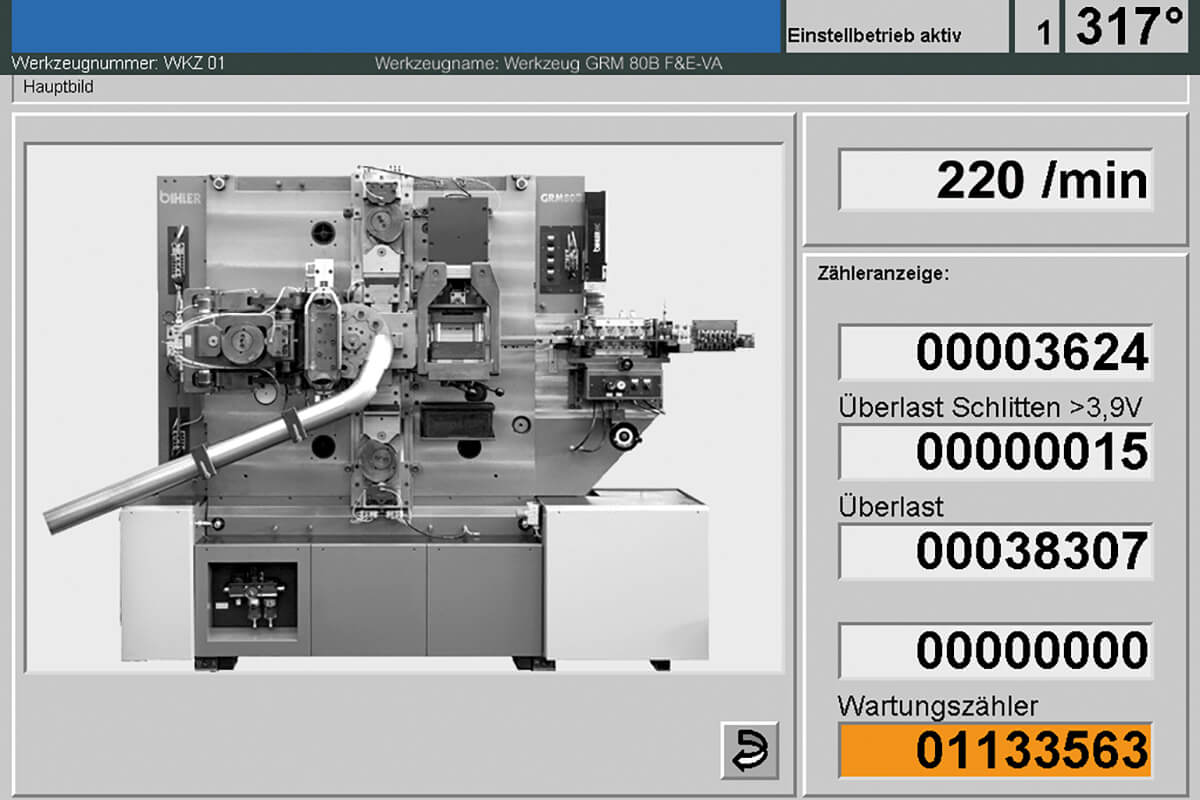

- High production speeds up to 220/min

- Very short tooling change-over times

- Perfectly designed for international use (only active parts have to be dispatched)

- Cost-effective all-in-one package

- Easy and secure operation with VariControl VC 1E

| Stroke rate | Max. 220 1/min. (cylindrical, straight bushes), max. 160 1/min. (flanged bushes, collar bushes) |

| Nominal forming capacity 50 kN, stroke 50 mm | |

| Bushing inner diameter | 15 mm – 40 mm |

| Bushing length | Max. 50 mm |

| Material | Strip thickness: max. 2 mm, strip width: max. 50 mm (depending on material and process) |

| Dimensions | Width 3,140 mm x depth 1,895 mm x height 2,030 mm |

| Weight | Approx. 4,800 kg |

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin