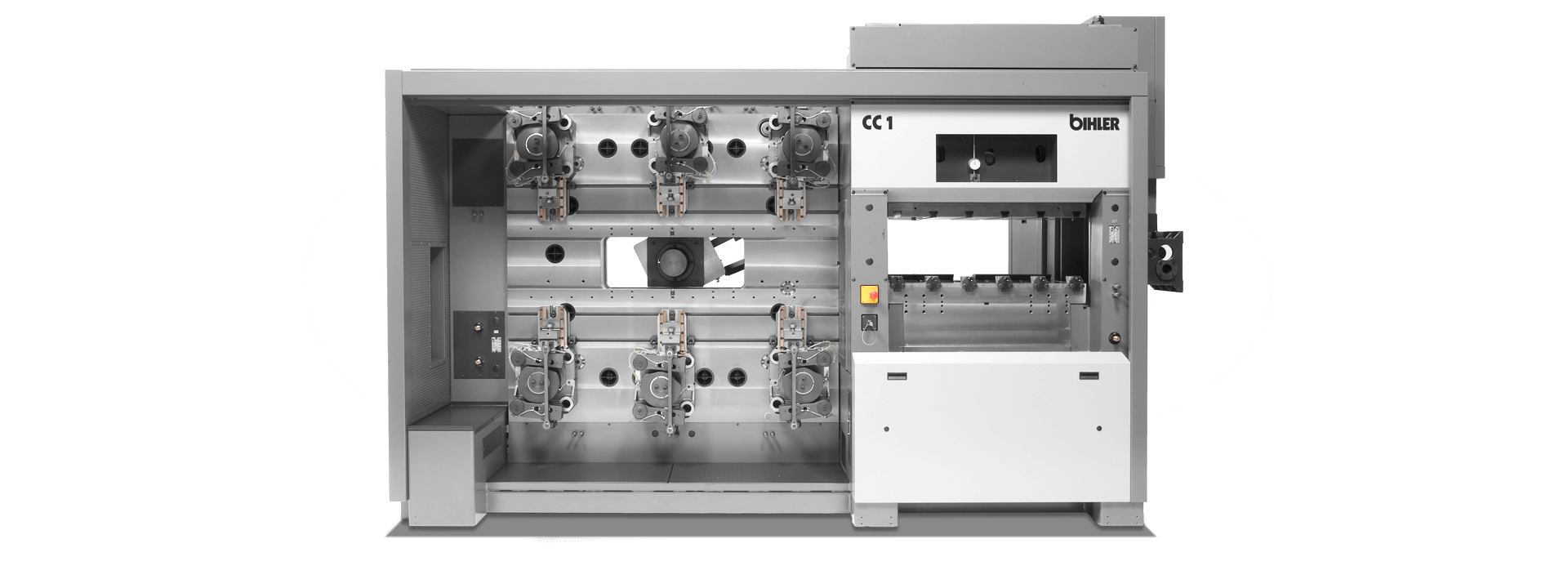

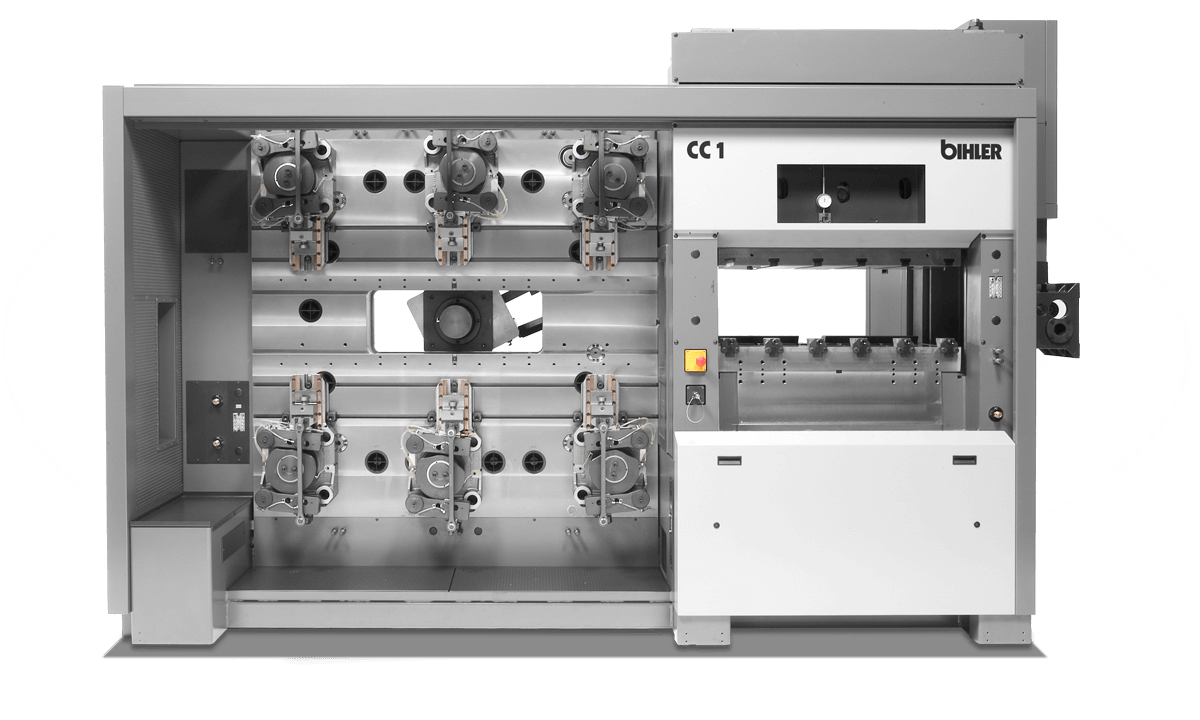

Powerful machining system for mass production of longer and larger-sized stamped and formed parts as well as sub-assemblies

- High production speeds of up to 200 1/min.

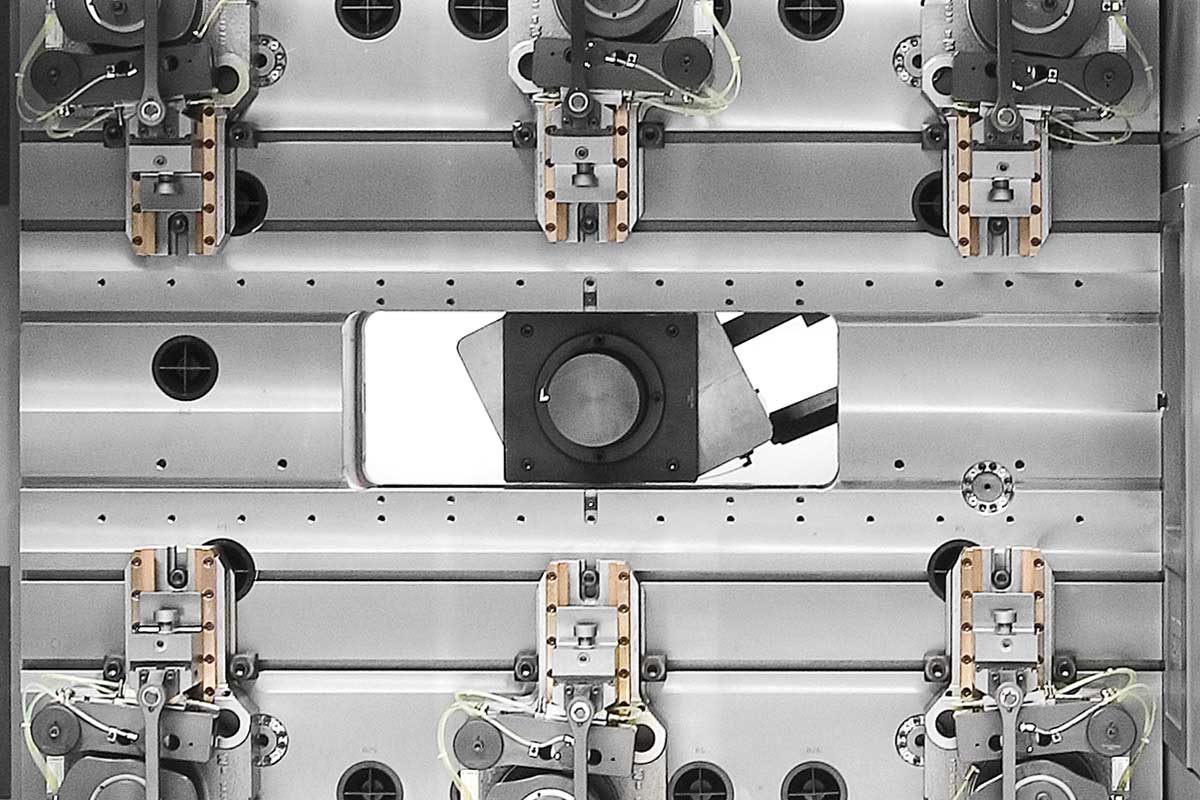

- NC feed units available for long feed lengths

- Strong 800 kN eccentric press arranged beside the work plate

- Extended press space for larger cutting tools

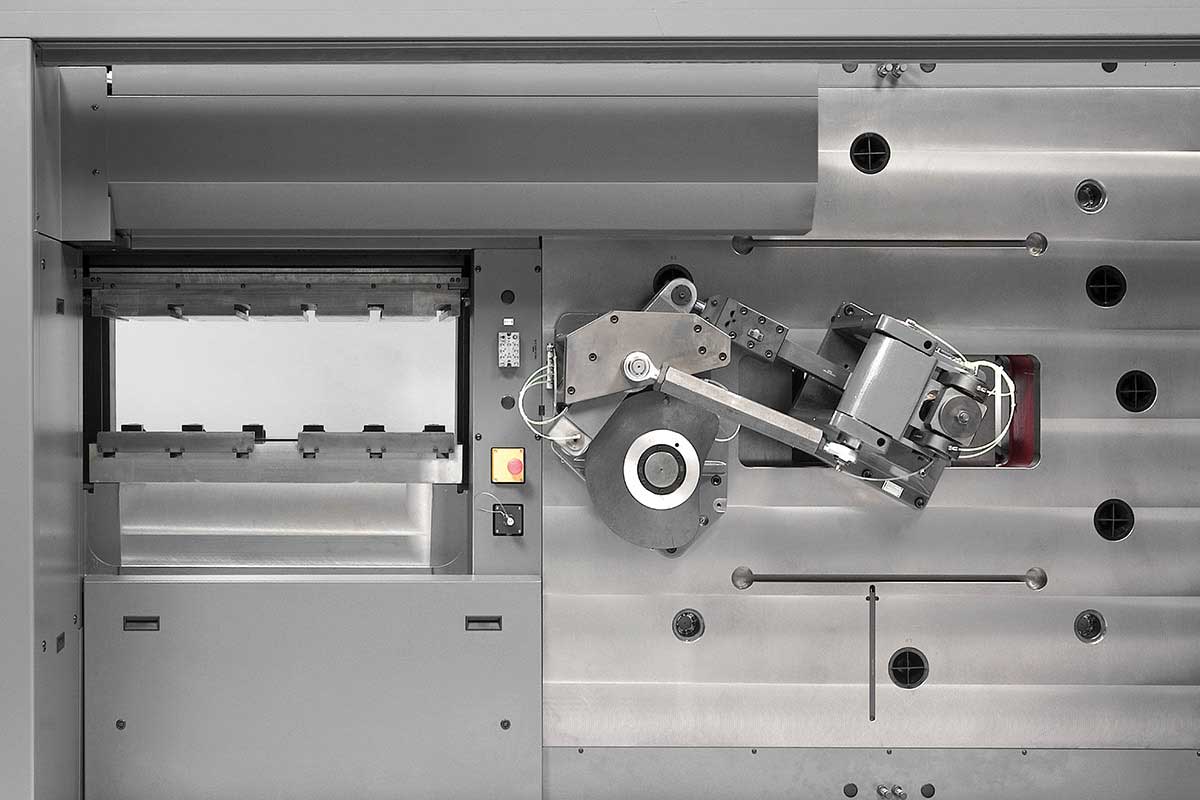

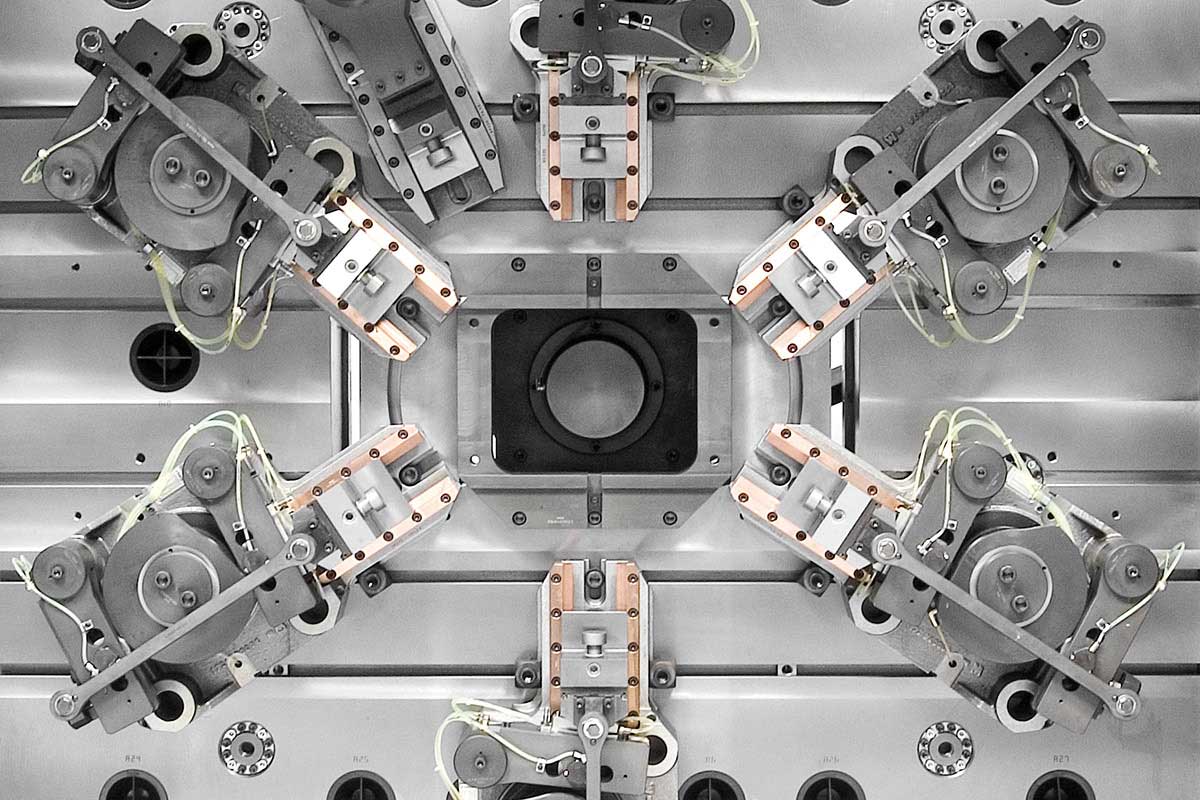

- Entire work plate available for additional processing steps (contact welding, tapping, inserting screws etc.)

- Large aperture in face plate to allow for several central mandrels

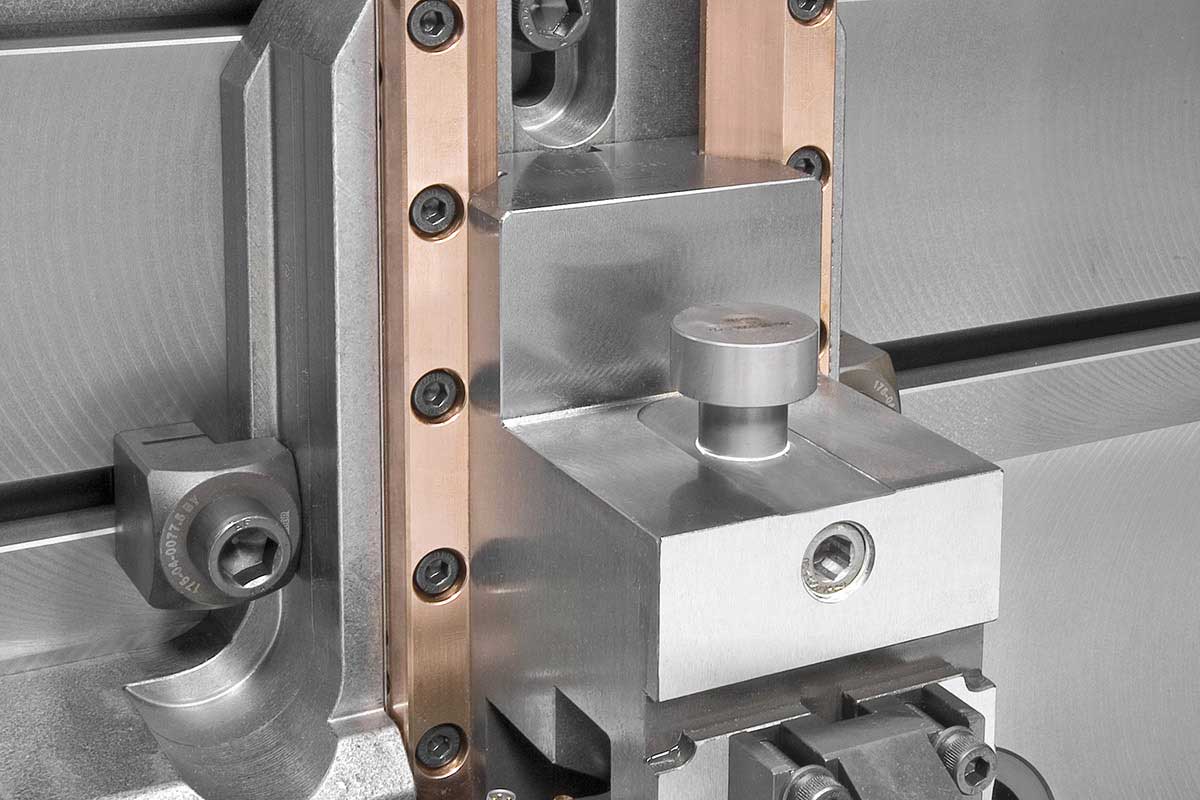

- Short changeover times with rapid tool clamping system

- Easy and secure operation with VariControl VC 1