Digital Tool for Production Optimization

With “Bihler Digital”, you can increase efficiency in your production. The software tool offers you clearly structured features for production analyses, order and information management. It is immediately ready for use in a plug & play process and requires no special customizing. This saves you the high installation costs of extensive MES systems.

In addition, “Bihler Digital” is the interface for offline operations such as programming, training and updates. Visualize your entire Bihler production, evaluate your production data quickly and easily and create your own statistics for every Bihler machine with VC 1 control.

Software: Digital App | Planning WebApp | bNX Design Software

Bihler Digital App

With the “Bihler Digital App”, you increase efficiency in your production.

Thanks to the modularity of the digital application, you fully exploit optimization potential on your machine. The focus is on analyses and adjustments to the plant as well as training your employees. The application is immediately ready for operation in a plug & play process without any programming effort.

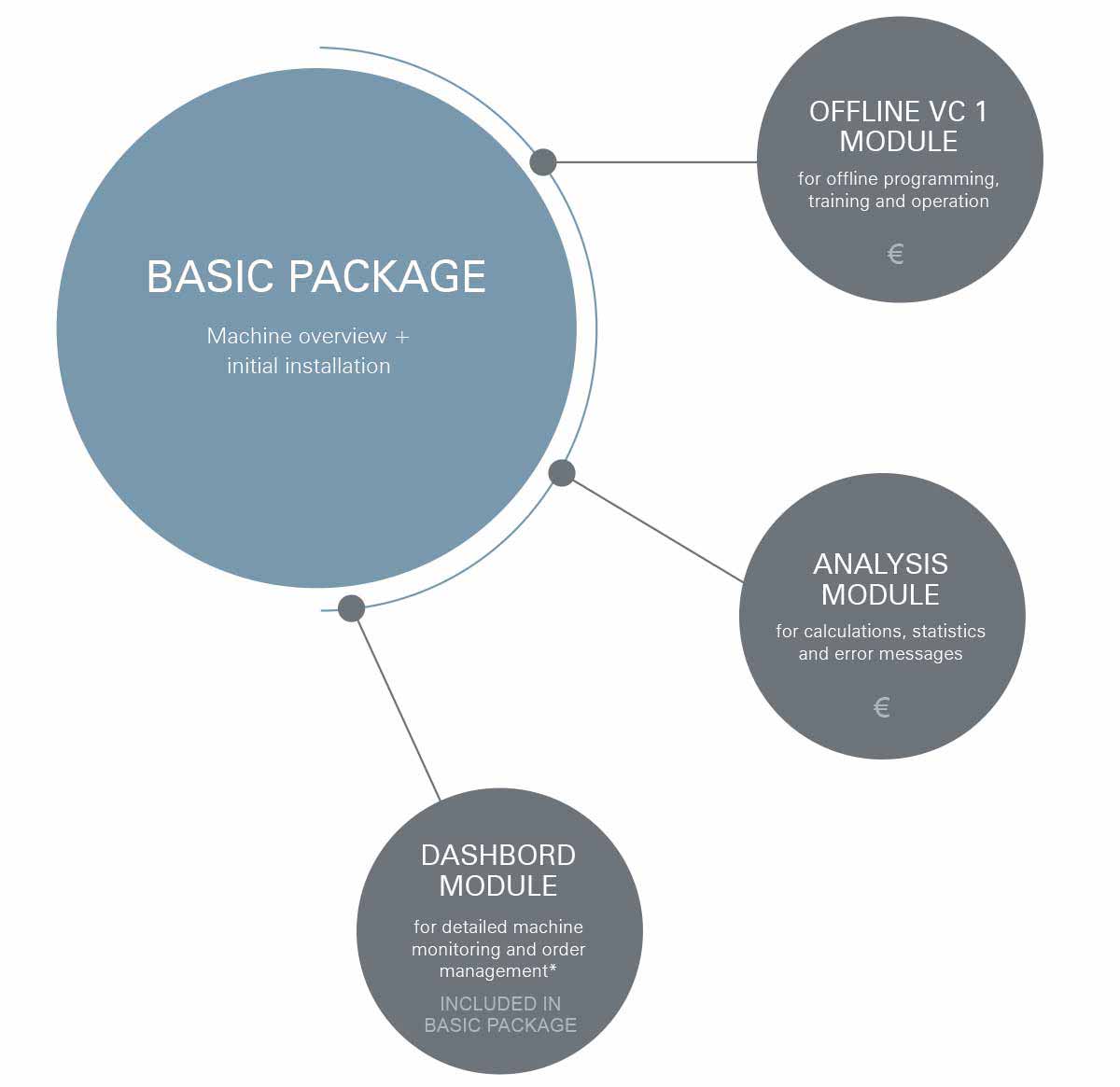

The “Bihler Digital App” currently consists of the “basic package” with machine overview and dashboard for machine management via a clear real-time display of the Bihler systems as well as the four flexibly usable additional modules “Analysis”, “Offline VC 1”, “Order Management” and “Animation”.

Modules

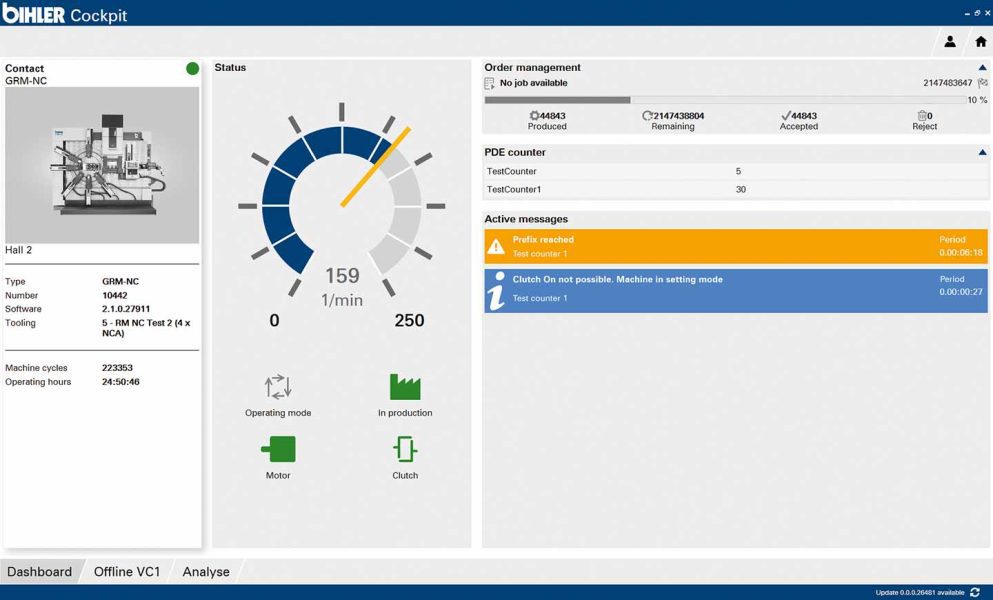

The dashboard module shows you the current state of your machine. In addition, you receive an overview of the current machine status and can track the progress of your production through order monitoring. With this comprehensive information, you will be able to introduce new orders in an even more targeted manner*.

The dashboard module shows you the current state of your machine. In addition, you receive an overview of the current machine status and can track the progress of your production through order monitoring. With this comprehensive information, you will be able to introduce new orders in an even more targeted manner*.

*Prerequisite is the VC 1 order monitoring module

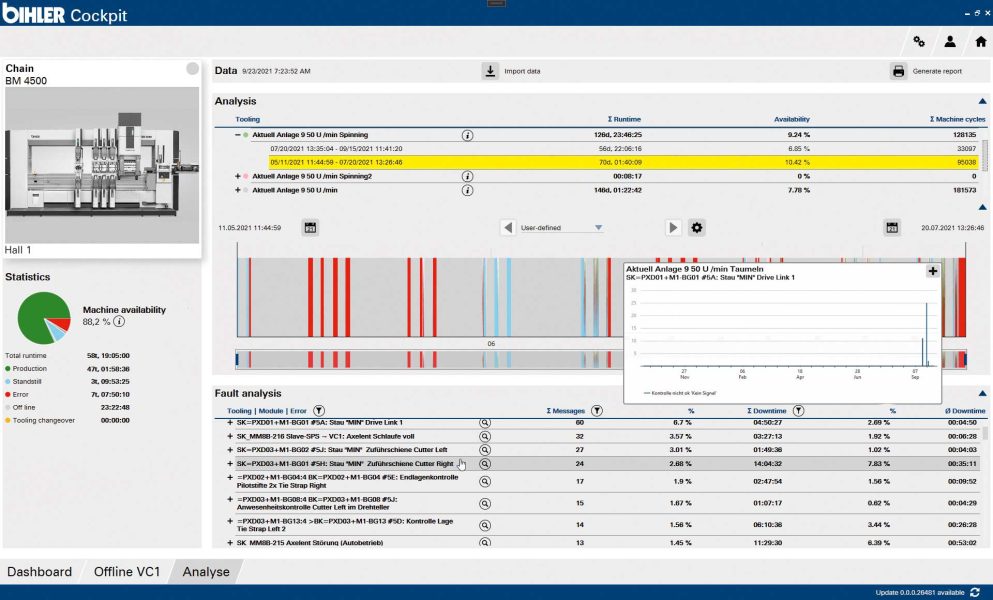

With the analysis module, you can quickly remedy any errors that occur. Systematically limit the errors by specifically filtering data from your machine and preparing it according to your requirements. This simply brings you to your personal trend statistics. In addition, you can use the analysis module to identify the most frequent faults in your plant and thus uncover targeted optimization potential – this is the basic prerequisite for achieving higher machine availability.

With the analysis module, you can quickly remedy any errors that occur. Systematically limit the errors by specifically filtering data from your machine and preparing it according to your requirements. This simply brings you to your personal trend statistics. In addition, you can use the analysis module to identify the most frequent faults in your plant and thus uncover targeted optimization potential – this is the basic prerequisite for achieving higher machine availability.

Our experts in the Consulting department will be happy to support you with an initial evaluation of your analysis data. They will evaluate the results of the defect analysis and give you recommendations for action to optimize the manufacturing processes. This additional service is included in the analysis module subscription. Of course, our specialist departments will also help you to implement the recommended optimization afterwards.

Your benefit: Optimizing your manufacturing processes will significantly increase the effectiveness and efficiency of your plants.

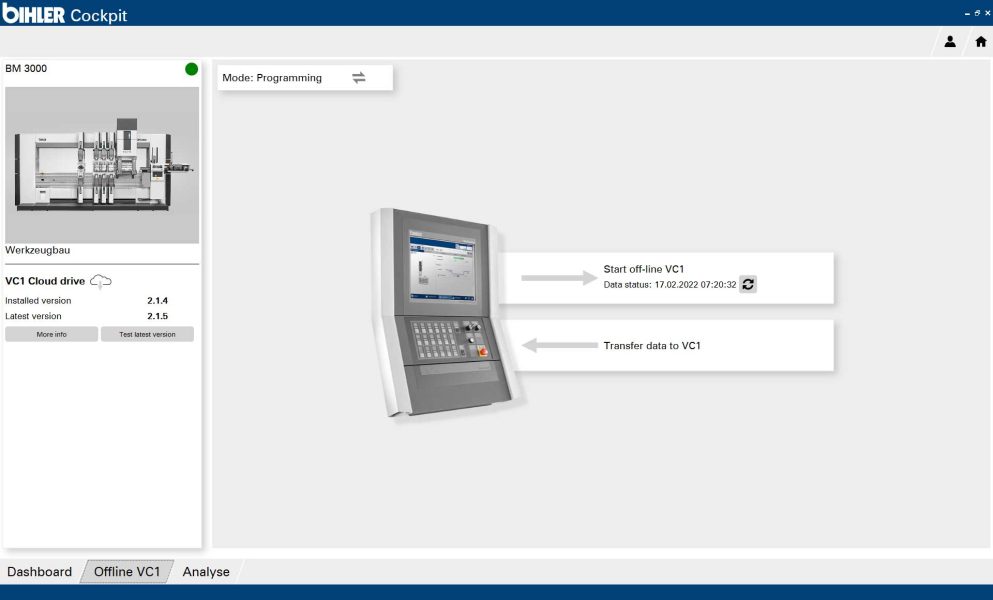

Do you need to change a program while shutting down the machine? You want to train your employees at the machine but not stop your production? Then the module “Offline VC 1” is exactly the right thing for you. Program and work in offline mode in the future and let the machine continue to produce. Thus, you reduce downtimes and save unnecessary costs.

Do you need to change a program while shutting down the machine? You want to train your employees at the machine but not stop your production? Then the module “Offline VC 1” is exactly the right thing for you. Program and work in offline mode in the future and let the machine continue to produce. Thus, you reduce downtimes and save unnecessary costs.

Modes Programming / Training

- Offline VC 1 programming: Extension and modification conveniently from your desktop computer in the office

- Offline VC 1 training: Training of employees at the office workstation without interruption of production

Product Details

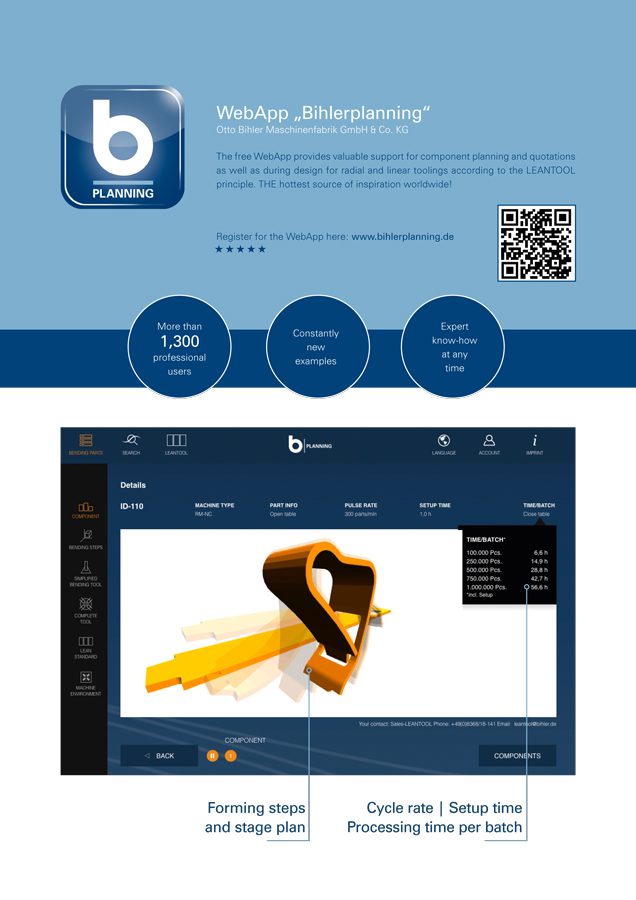

Planning WebApp

The WebApp is the ideal tool for planners and designers. It provides valuable support for component planning and quotations as well as during design for radial and linear toolings according to the LEANTOOL principle. That is why the free App contains a sample database with a wealth of Bihler knowledge as well as tooling designs (strip parts and wire parts) in STEP format.

The WebApp is a useful source of inspiration for innovative solutions using the principle of similarity.

- It offers an easy and quick overview of all aspects for implementing stamped and formed parts, wire parts and progressive parts (bending sequences, tooling).

- Additional information such as production speed, setup time and processing time per batch is clearly indicated.

We are continuously extending the case studies and other features for component and tool planning for you.

You can register at www.bihlerplanning.de. You will then be able to access and use our WebApp free of charge.

The hottest source of inspiration

- More than 1,300 professional users

- Constantly new examples

- Expert know-how at any time

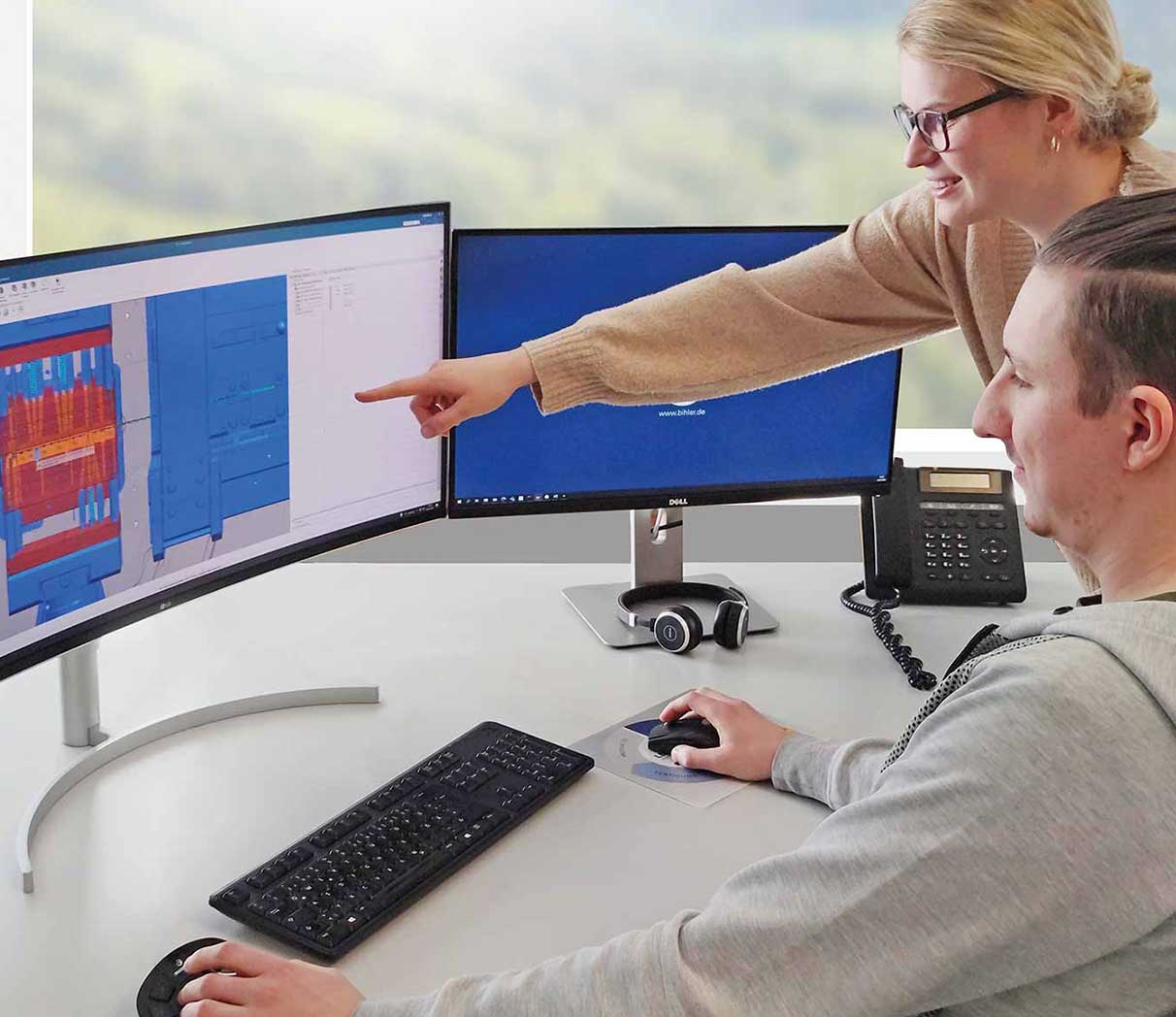

bNX Design Software

The modular Bihler bNX technology software provides optimum support for the virtual modelling of your products as well as the development and design of Bihler stamping and forming tools.

With this globally unique solution for system engineering and tool design, you benefit from shortest development times, significantly lower development costs, optimized products with higher quality and reliable tools with higher output rates. In addition to the fully integrated Bihler Technology Software, bNX also contains the basic software modules of Siemens NX for optimum, market oriented design. The software allows you to quickly adapt to changing product or production requirements – for instance with the consistent templates for our modular LEANTOOL tool kit.

bNX Software Products

Implement new tools easier, faster and cheaper

Implement new tools easier, faster and cheaper

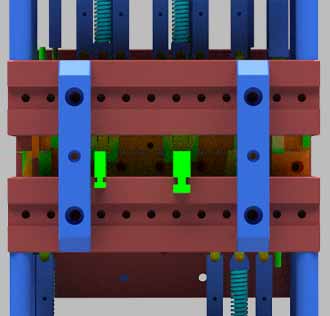

The Bihler bNX Software is based on the Siemens NX 3D-CAD system. With the powerful features of this system, you handle demanding assemblies effectively and quickly create complex designs.

The fully integrated Bihler software provides unparalleled support when designing tools both for Bihler machines as well as for progressive presses. Forming studies are created quickly and easily and used to generate the resulting strip layout. Create the 3D geometry and kinematics of your machine and tools using the provided 3D standard parts. Simulate all movements of your entire Bihler system in 3D. Then optimize the motion sequences and derive the required curve profiles or NC programs for the actual machine.

Your benefit: Significantly reduced development times as well as reliable tools with maximum cycle rates.

Optimum motion sequences for your Bihler machines

Optimum motion sequences for your Bihler machines

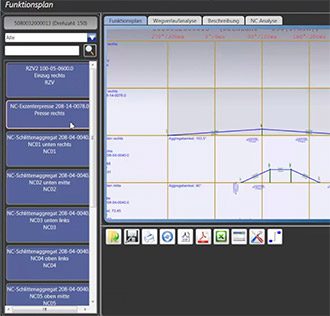

The Kinematics Express software is a CAD-independent solution for the virtual design of motion sequences for cam-controlled and NC-controlled Bihler machines.

Quickly and easily define all your machine movements in relation to each other. The result are optimized motion profiles that can be output as easy-to-use contours in DXF or DWG format to create cams for mechanical machines. When using NC-controlled machines, the generated NC programs are transferred directly to the Bihler VC 1 control system.

Your benefit: With this easy-to-use software application, you quickly and reliably determine the optimum motion sequences for your Bihler machines independent of a CAD system, considering different motion laws and overlaps.

Library with precise geometries of your machine

Library with precise geometries of your machine

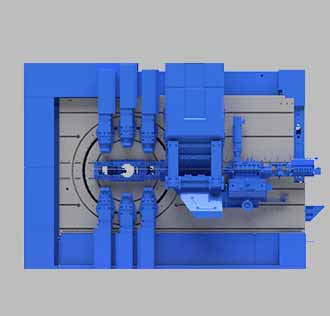

The Bihler 3D machine components program provides you with the 3D geometries of your Bihler machine in the formats STEP, DXF and Siemens NX in a library.

This allows you to integrate the Bihler machine in your CAD system during design and construction of your tools.

Your benefit is the availability of precise geometries of your Bihler machine in your preferred CAD environment.

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin