New Perspectives for Your Production

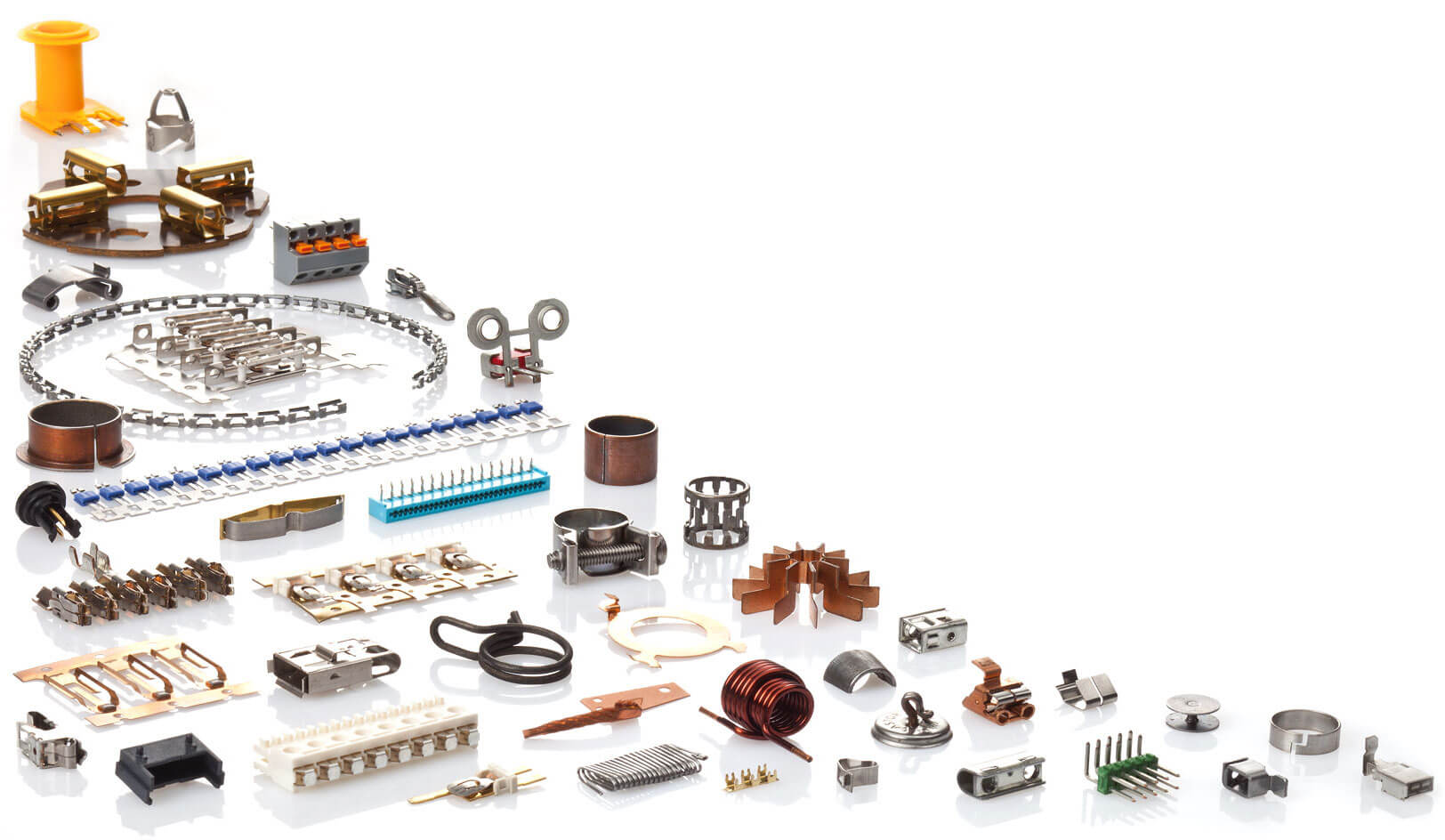

Achieve unmatched precision, reduce unit costs, and maximize efficiency with the advanced RM Series stamping, forming, multi-slide machines. These cutting-edge solutions redefine what’s possible in the production of stamped and formed parts, especially with thin, high-strength steels. The RM 40, RM 40KS and RM 40P models deliver exceptional performance, helping you stay ahead in competitive markets.

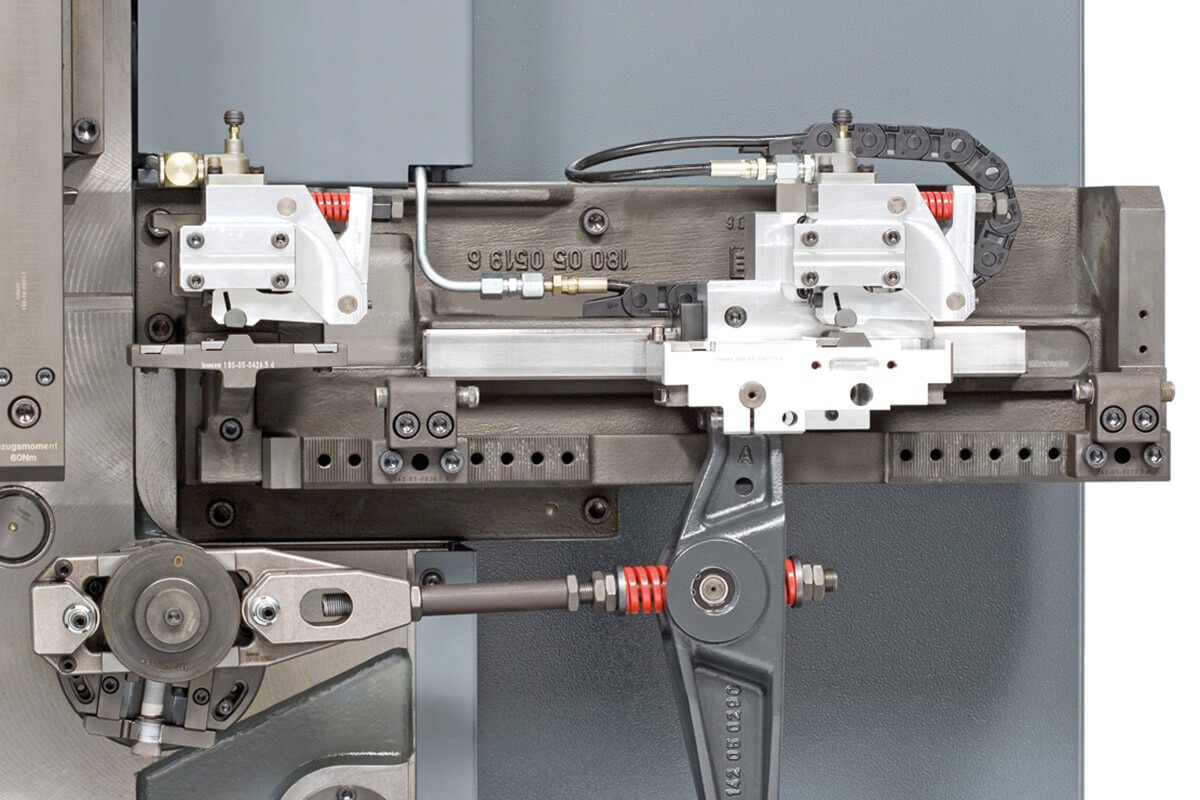

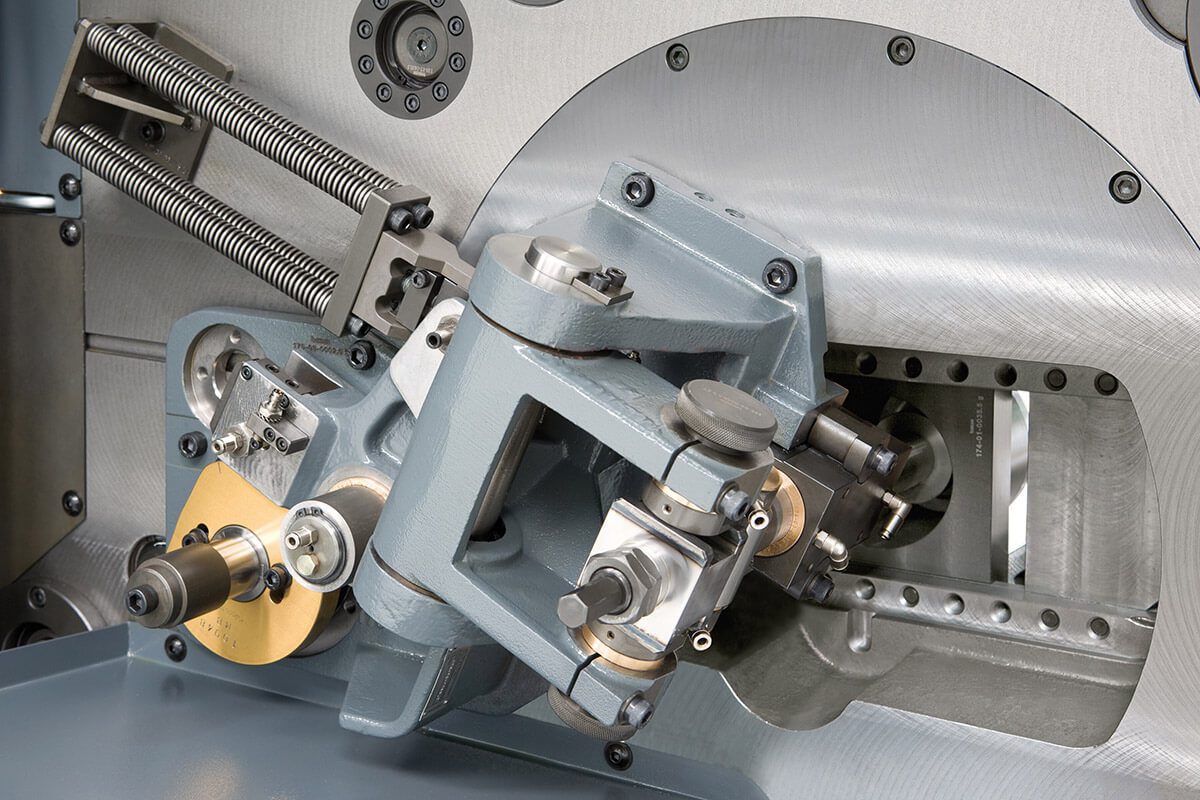

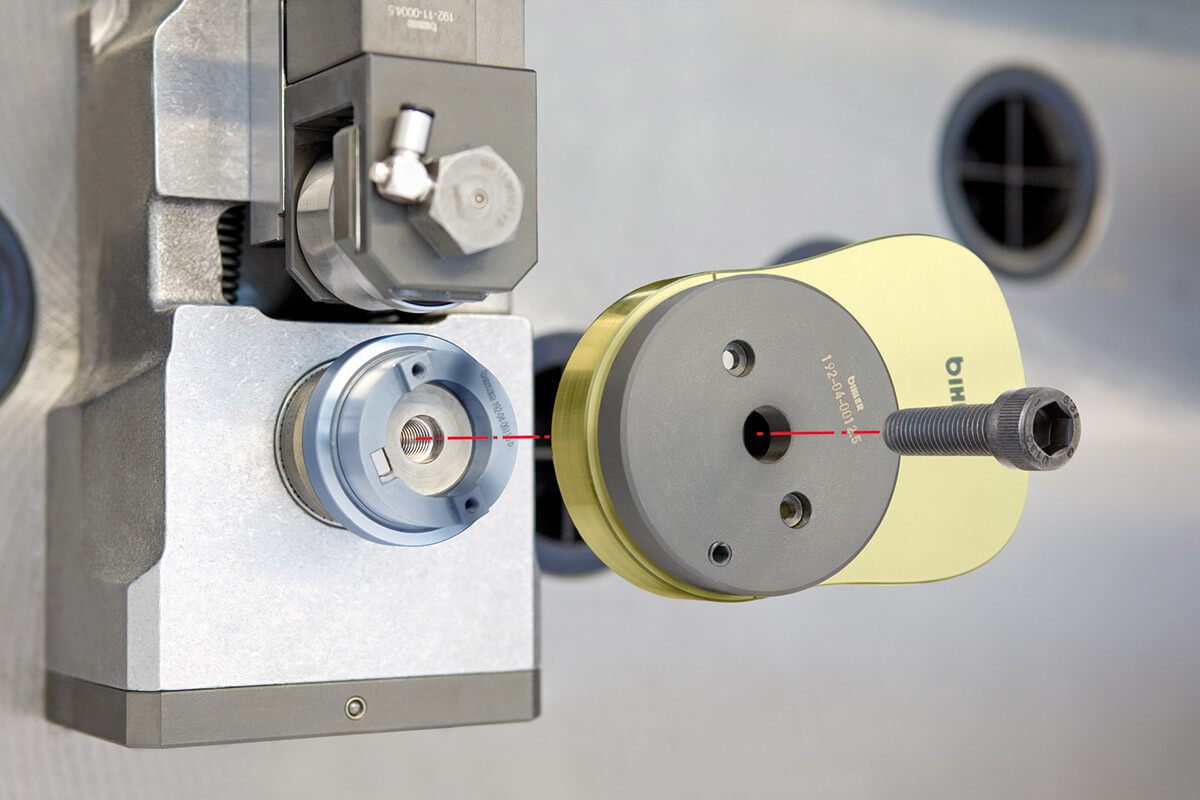

Designed with open accessibility, a wide range of process steps can easily integrate with the RM machines. Their user-friendly design ensures seamless retrofitting and maintenance, saving you time and effort. Powered by state-of-the-art control technology, these machines guarantee superior uptime, process reliability, and exceptional output quality.

Take your production to the next level.

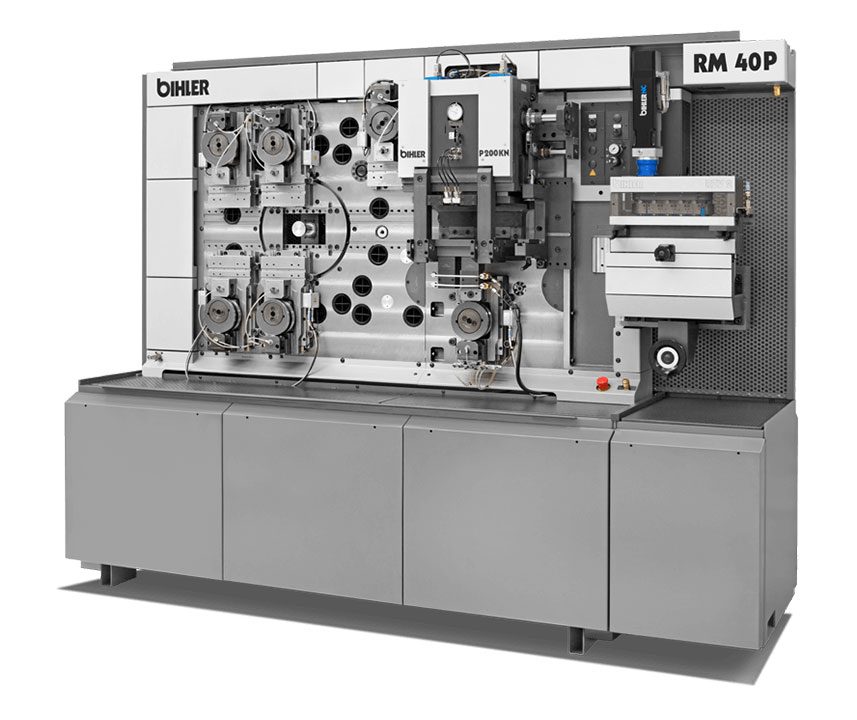

Machine Details

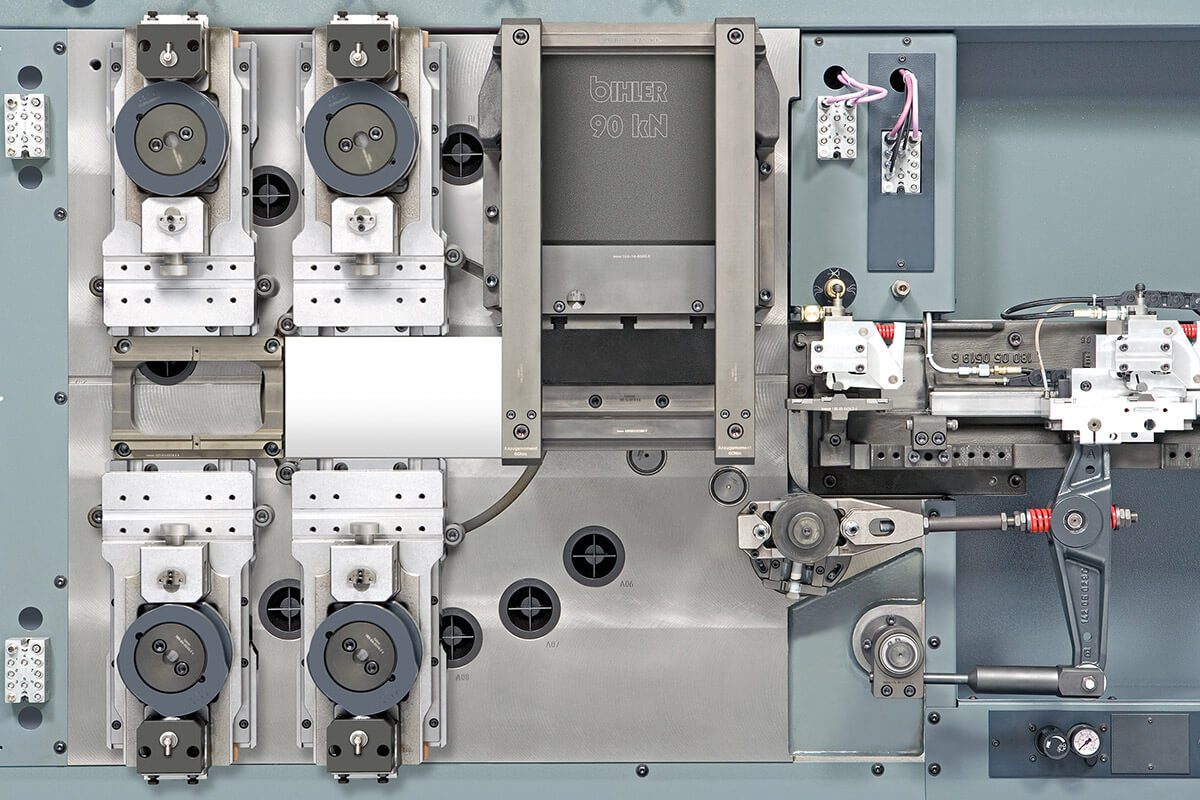

Universally applicable, powerful machine system for mass production of larger stamped and formed parts as well as sub-assemblies

- High production performance up to 350/min.

- Separate press module with 200 kN two-point eccentric press

- More than 1,400 mm of manufacturing space in case of linear toolings

- Lots of space for integration of additional processing units (contact welding, tapping, inserting screws etc.)

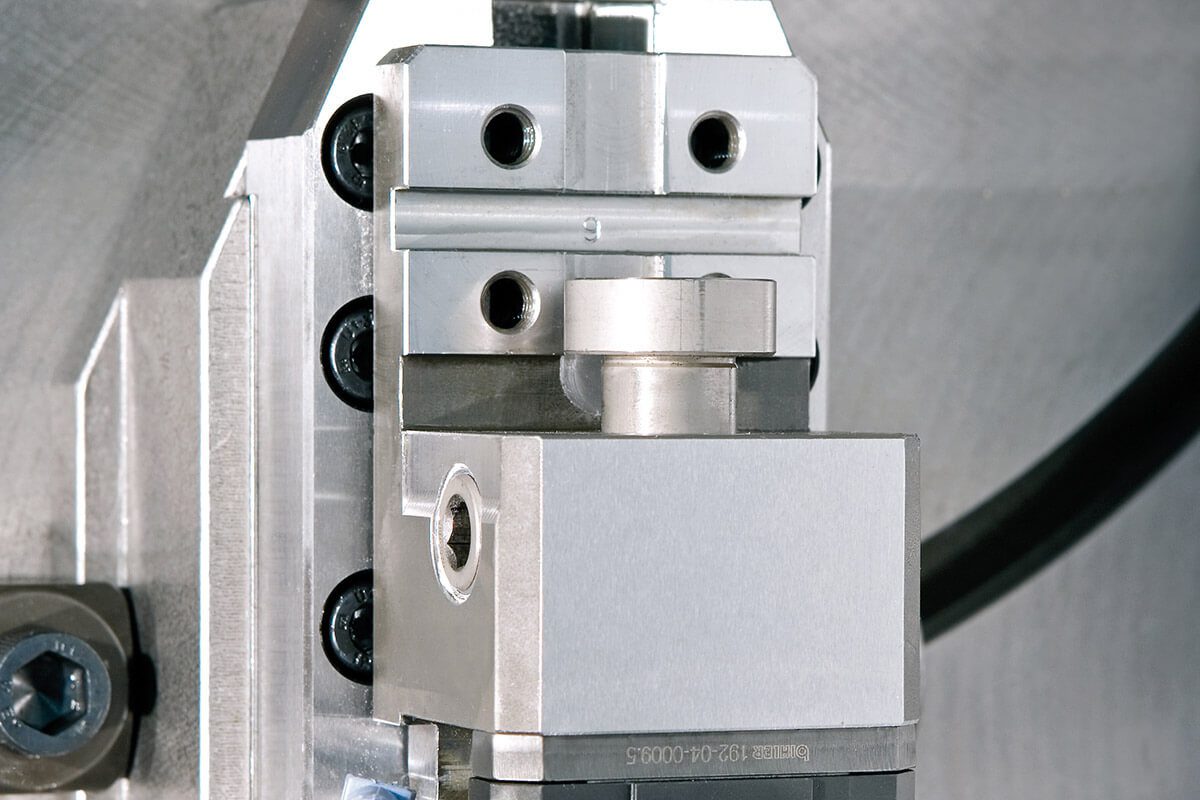

- Tool clamping system provides minimum set-up time

- VariControl VC 1 for intuitive handling

Production of “Technical Springs”

| Stroke rate | Steplessly from 5 to max. 350 1/min |

| Nominal forming force max. 60 kN, stroke max. 50 mm | |

| Servo feed: any, mech. feed: max. 240 mm, with feed cycle reduction (as option) | |

| Material | Strip thickness max. 4 mm, strip width max. 60 mm (larger strip width on request), wire Ø max. 4 mm (depending on material and process) |

| Width 3,090 mm x depth 2,026 mm x height 2,320 mm | |

| Weight | Approx. 3,900 kg (without tooling) |

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin