Upgrade your existing Bihler machines for new tasks. With the cost-effective BC R Retrofit package, this can now be done quickly and easily in three steps:

– We deliver the required machine components to

your site.

– Service technicians will then retrofit your machine

and install the BC R control system.

– Commissioning and approval.

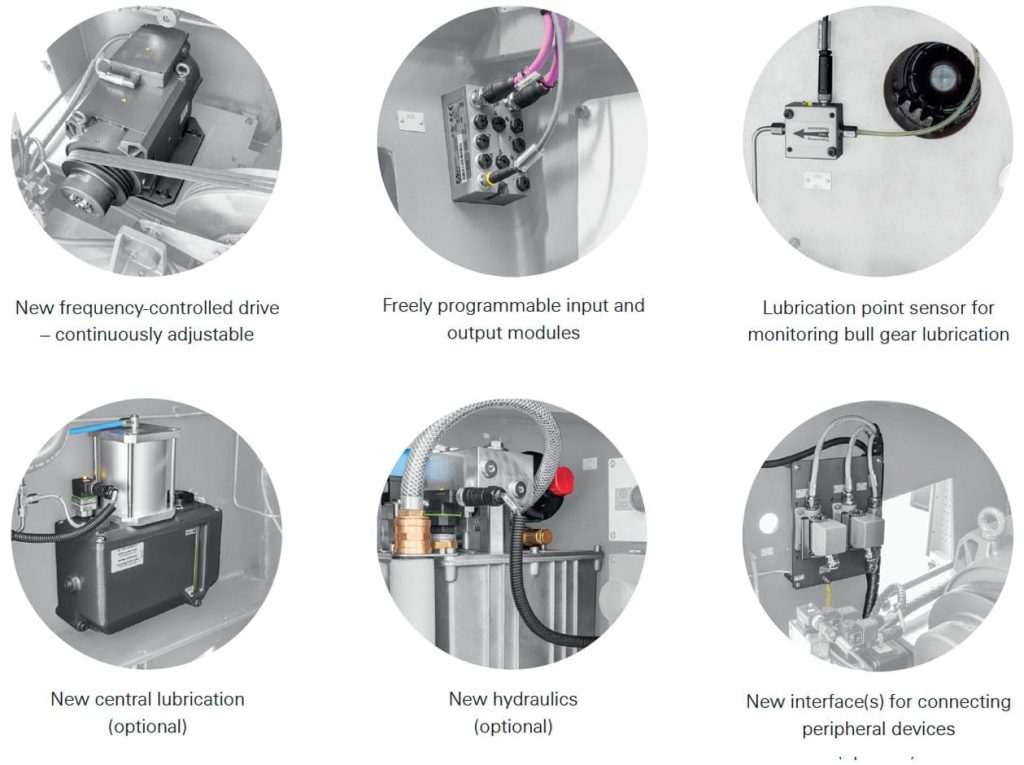

The advantages of doing the retrofit: The machine is up to date, with full spare parts support, and as an option, network-capability for the digital age. Additional features, such as straightforward operation of the control system, monitoring functions, and manual operations, will make your machine even more productive.

Time required for the entire process: approximately one week!