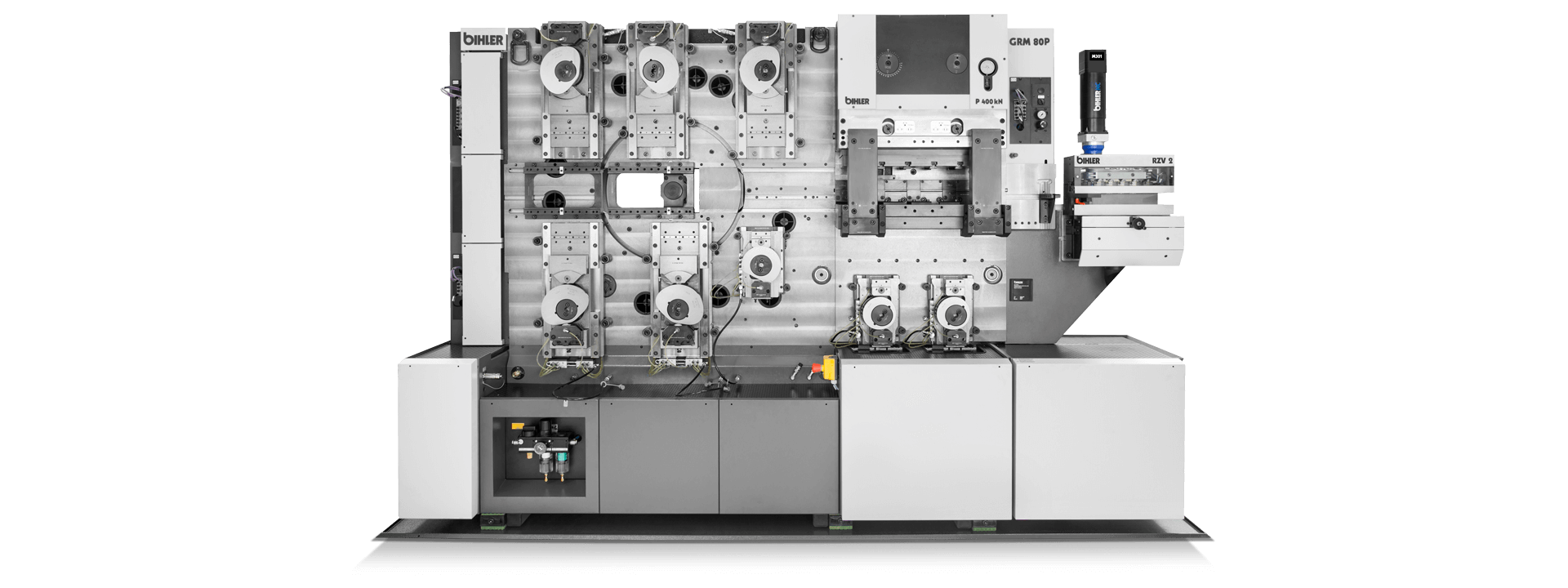

Powerful machining system for mass production of larger stamped and formed parts as well as sub-assemblies

- High production speeds of up to 250 1/min.

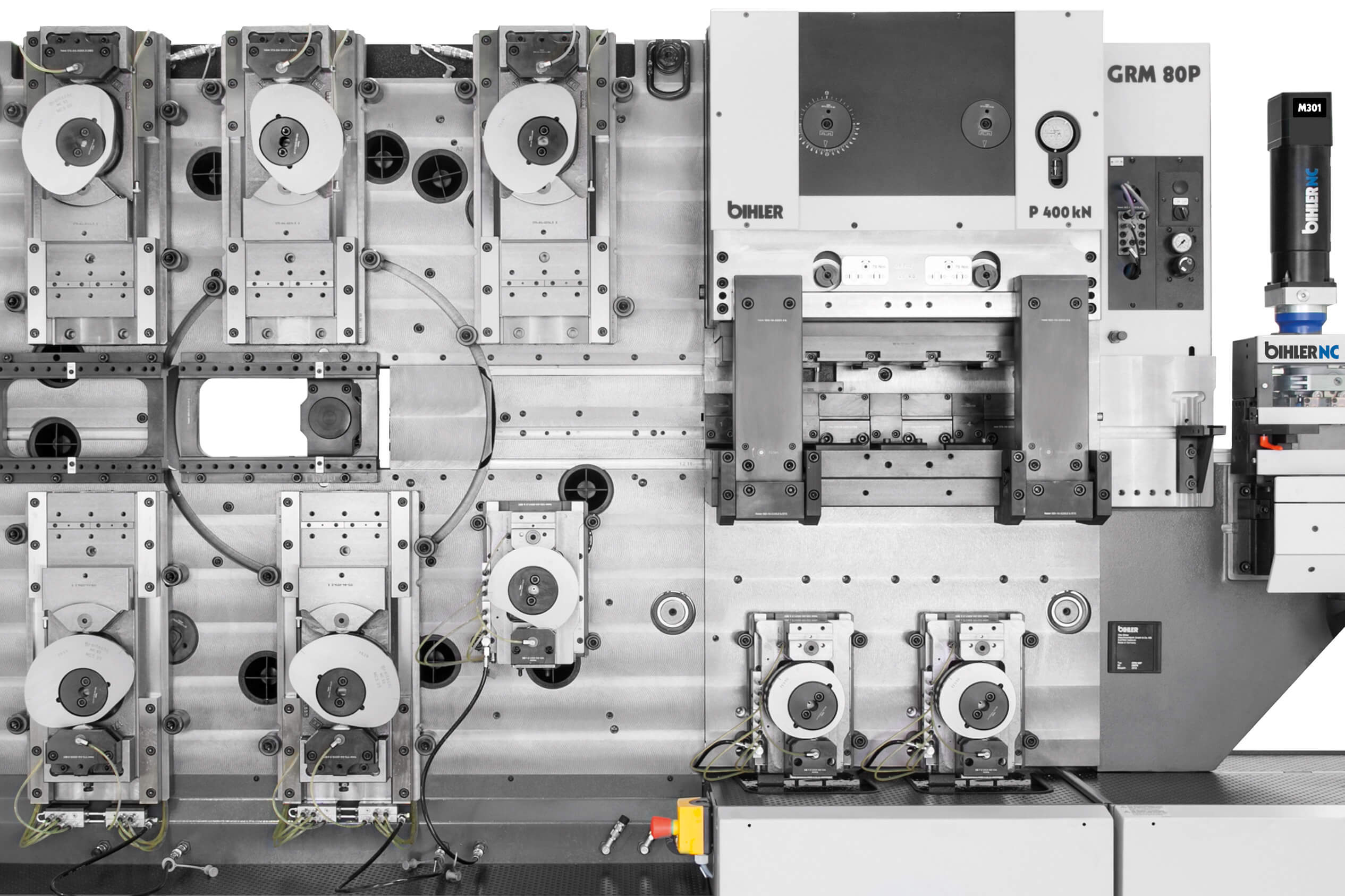

- Maximum processing room thanks to the spatial division of stamping and forming operations

- More than 2,100 mm travel for linear tool applications

Strong 400 kN two-point eccentric press with large installation capacity for bulky cutting tools - Easy integration of additional processing units (contact welding, tapping, inserting screws etc.)

- Large central aperture in the work plate for flexible central mandrel movements

- Easy to use VariControl VC 1 with 15“ touch screen

Production of “grounding contacts”