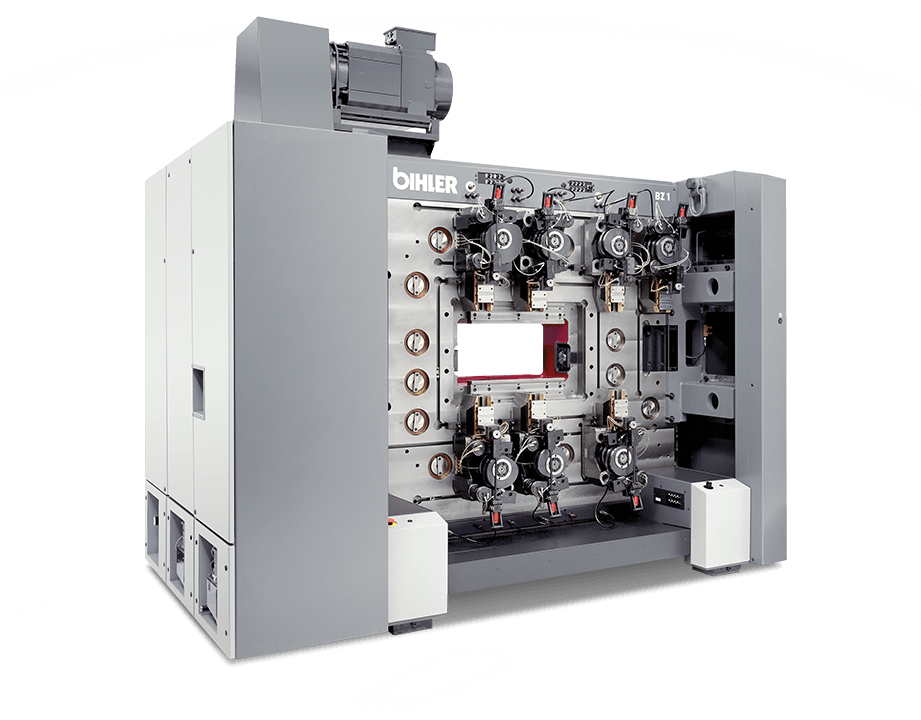

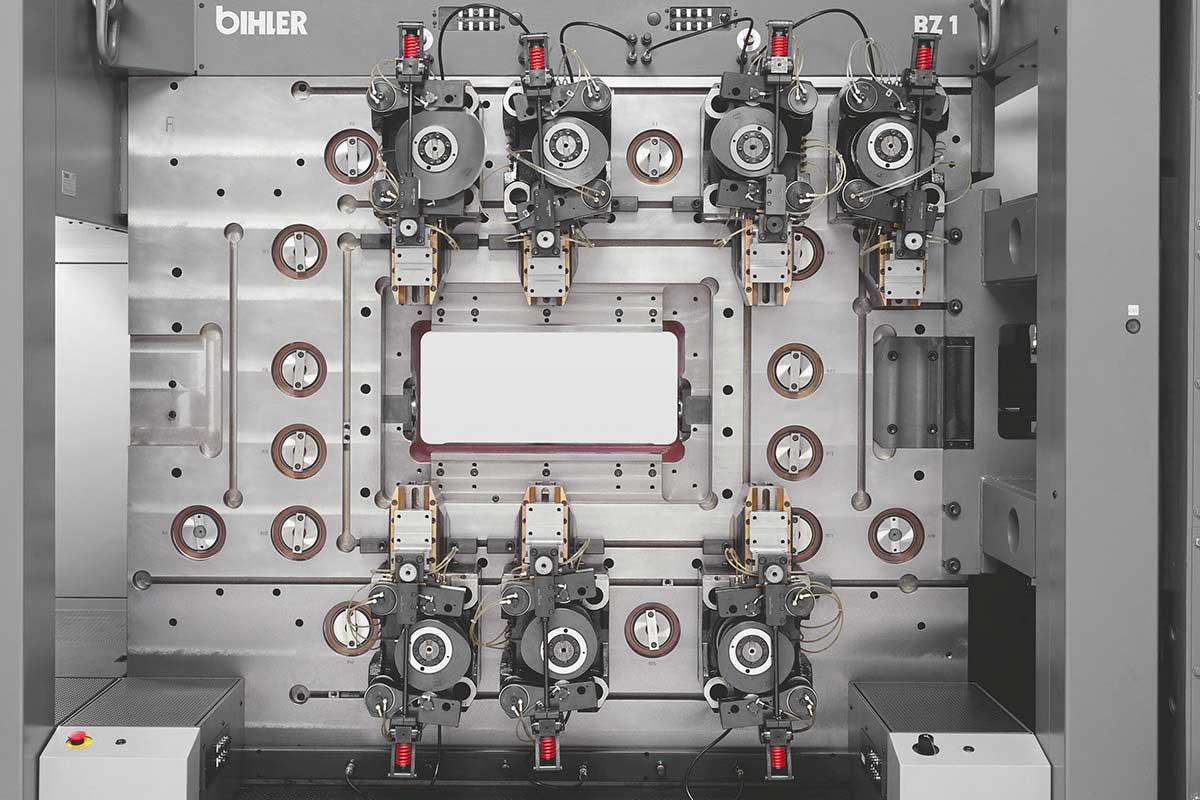

Flexible Manufacturing Systems for Maximum Forming Capacity

New applications are calling for new ideas. They require machine concepts which can flexibly be adapted to new manufacturing strategies in order to cope with ever more extensive and varying applications to be handled. This prerequisite is complied with the powerful processing centers BZ 1 and BZ 2 which cover all of the possibilities of BIHLER multi-technology.

The compact machine systems are used for combined punching, bending, welding, assembling, tapping, screw insertion, etc. Even metal-cutting operations can be integrated into the production processes. The machine concept encompasses two independent processing planes arranged parallel to each other, which can either be used separately or jointly for the production of larger-sized parts and assemblies. The BZ are suited to implement radial as well as linear tooling solutions. The multi-axis VariControl VC 1 guarantees easy handling and maximum process safety.

Contact Us