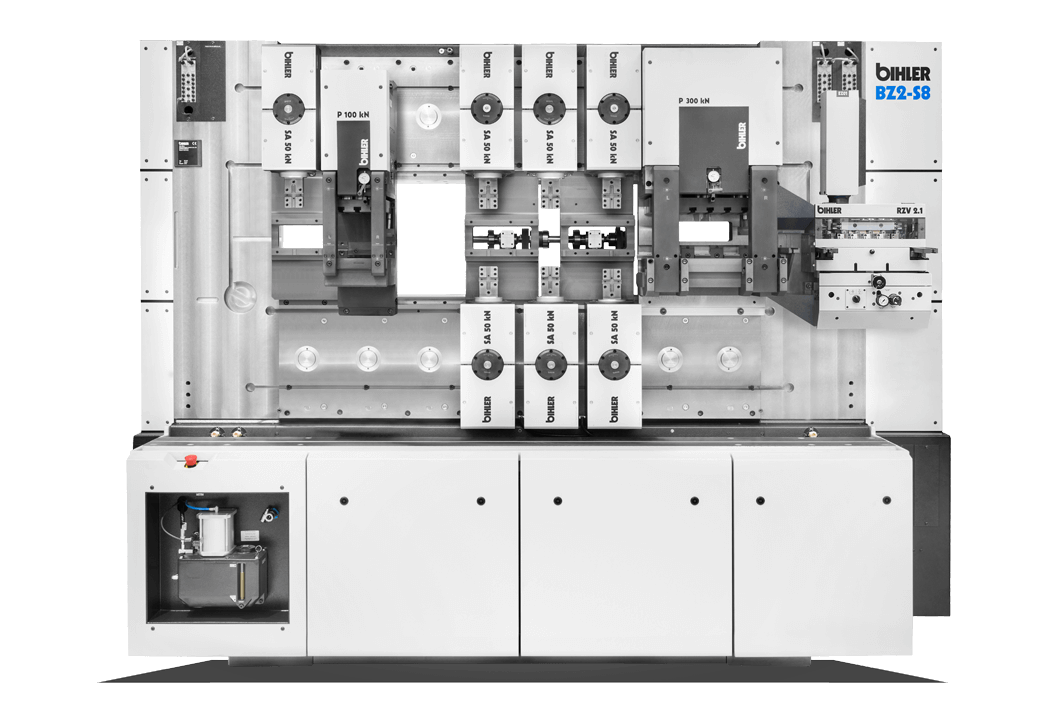

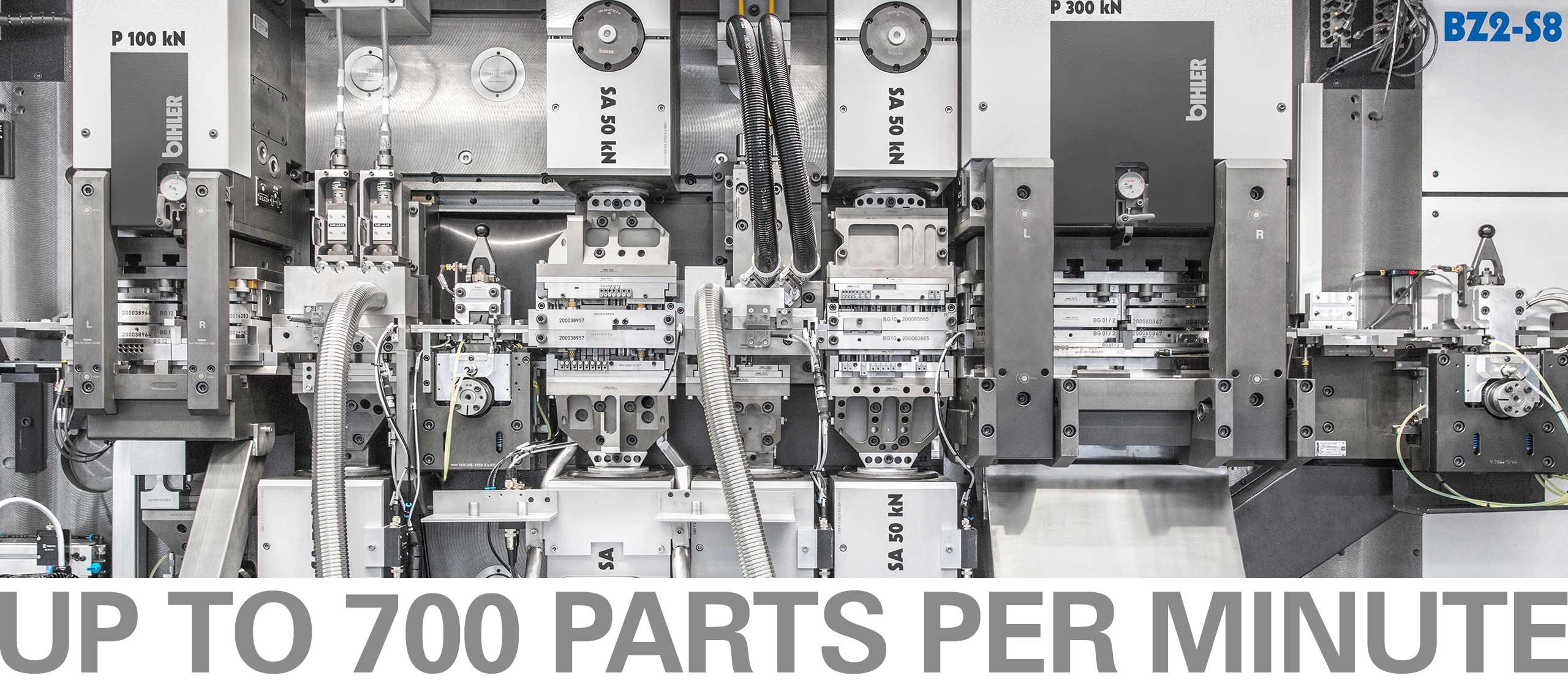

Cam Disk Technology with Innovative Features

With the new BZ2-S8, Otto Bihler Maschinenfabrik is presenting the latest generation of its proven series of processing centers. Many of the system’s innovative features help take conventional disk cam technology to new performance heights – with increased production speeds and reduced maintenance costs.

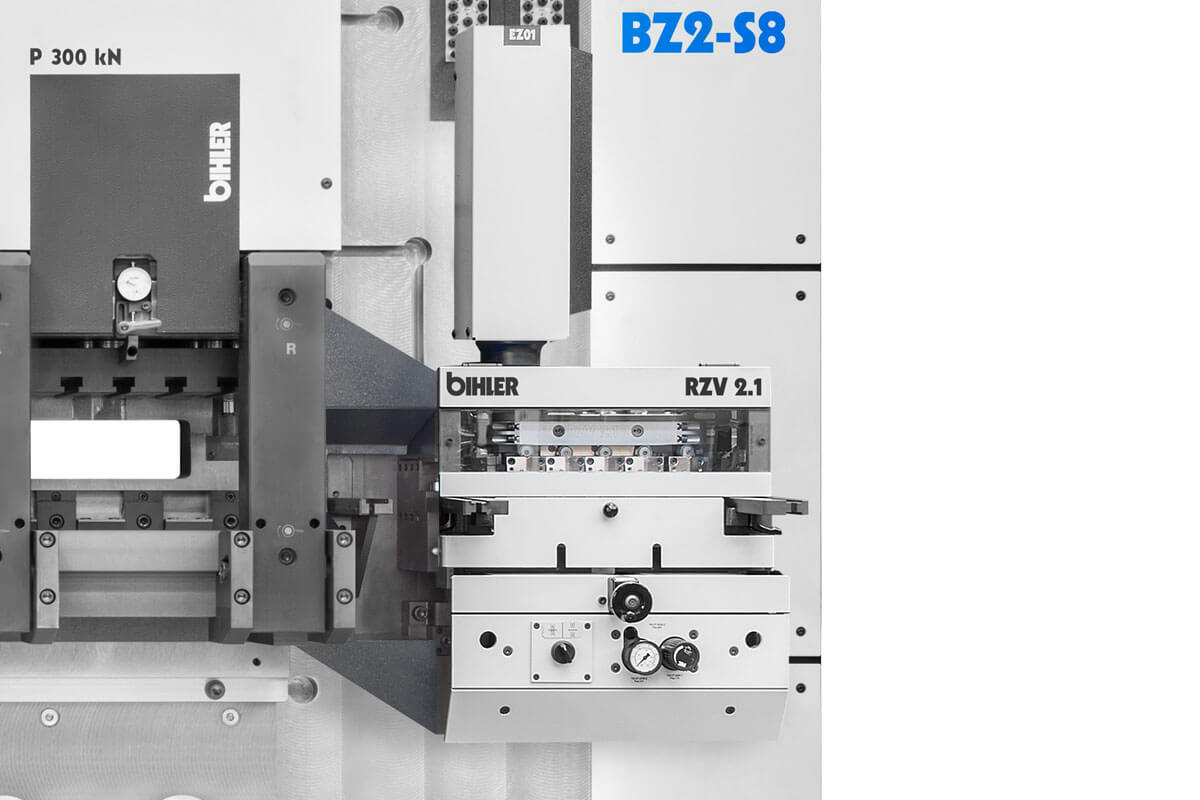

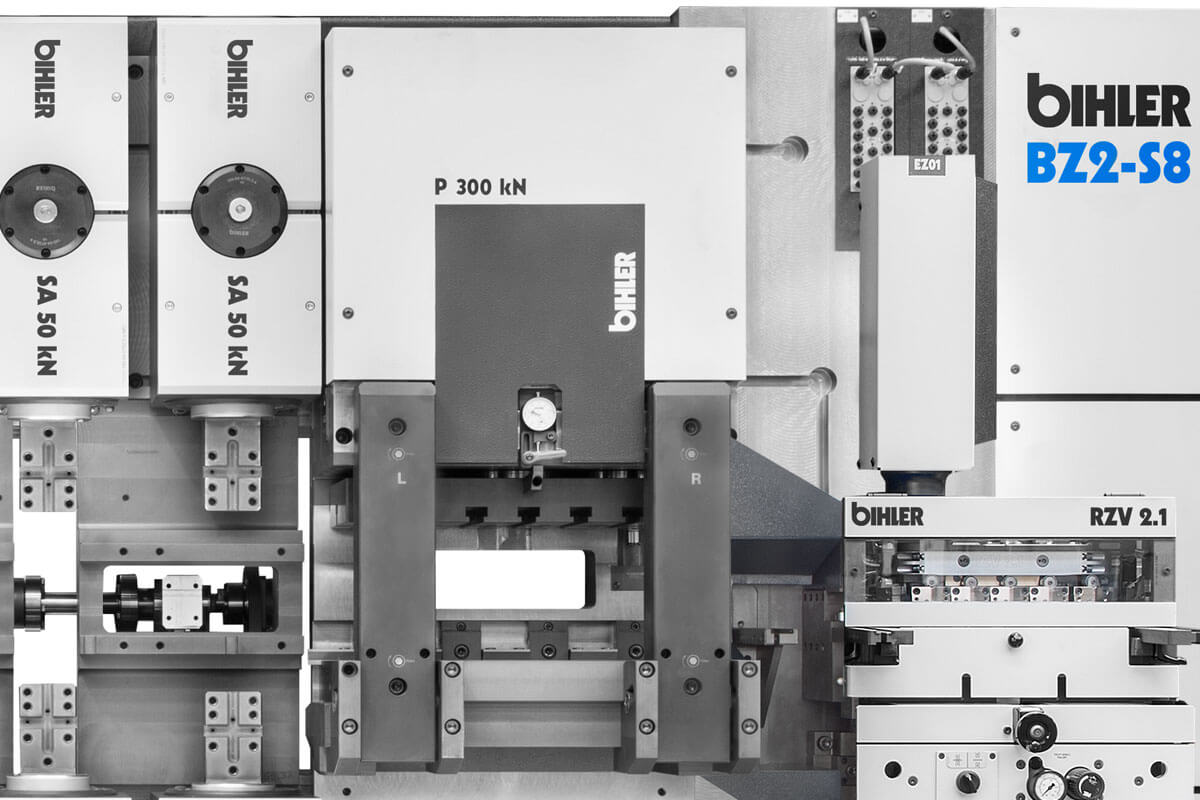

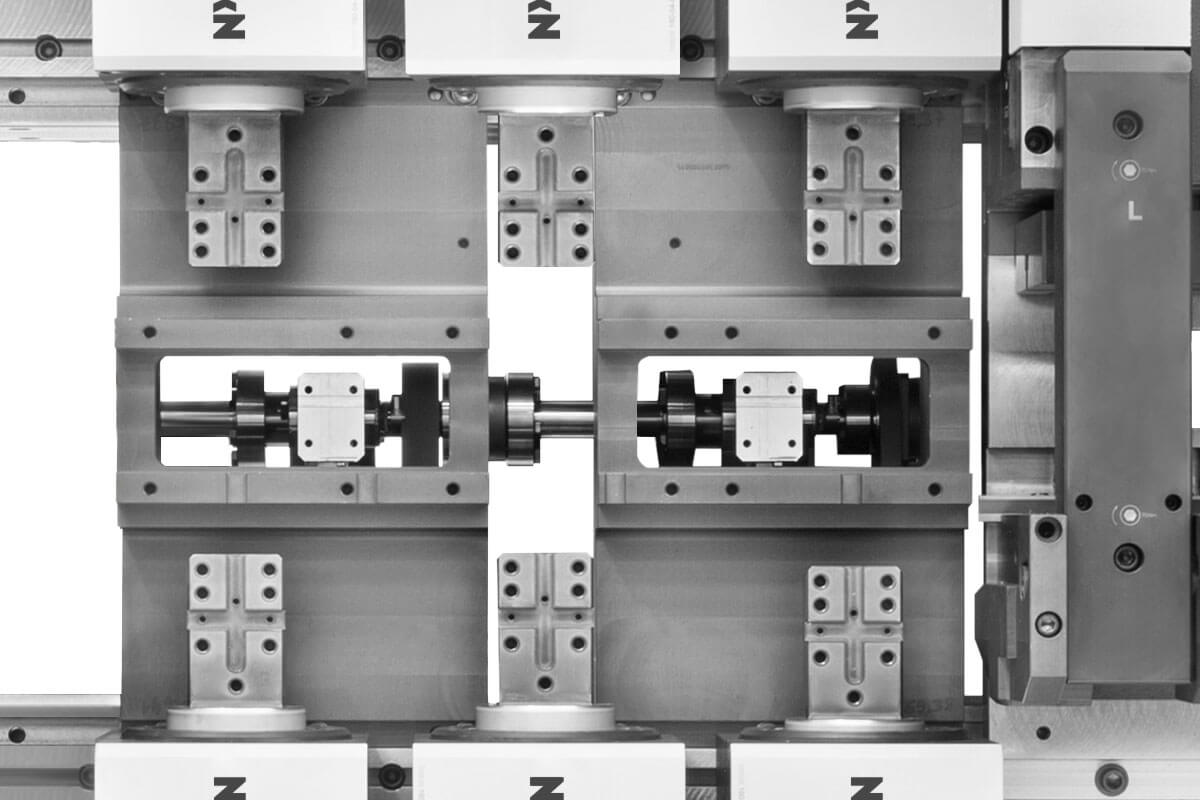

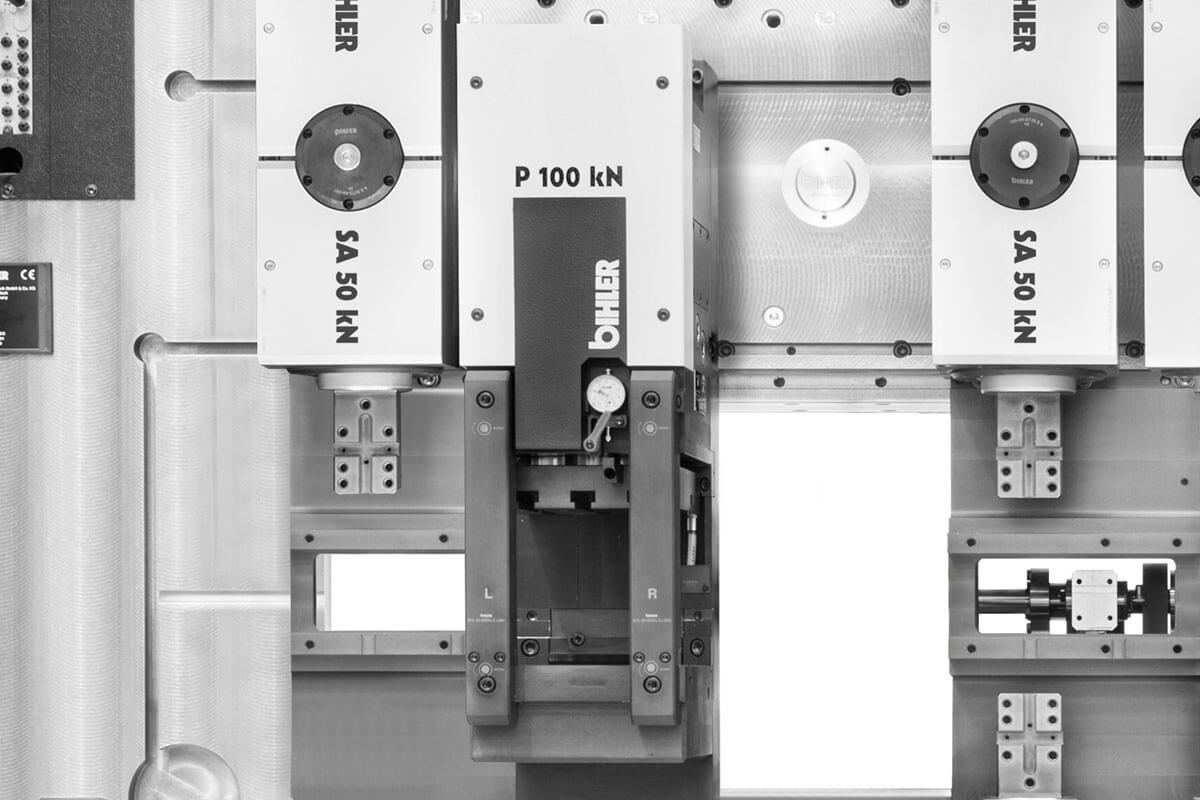

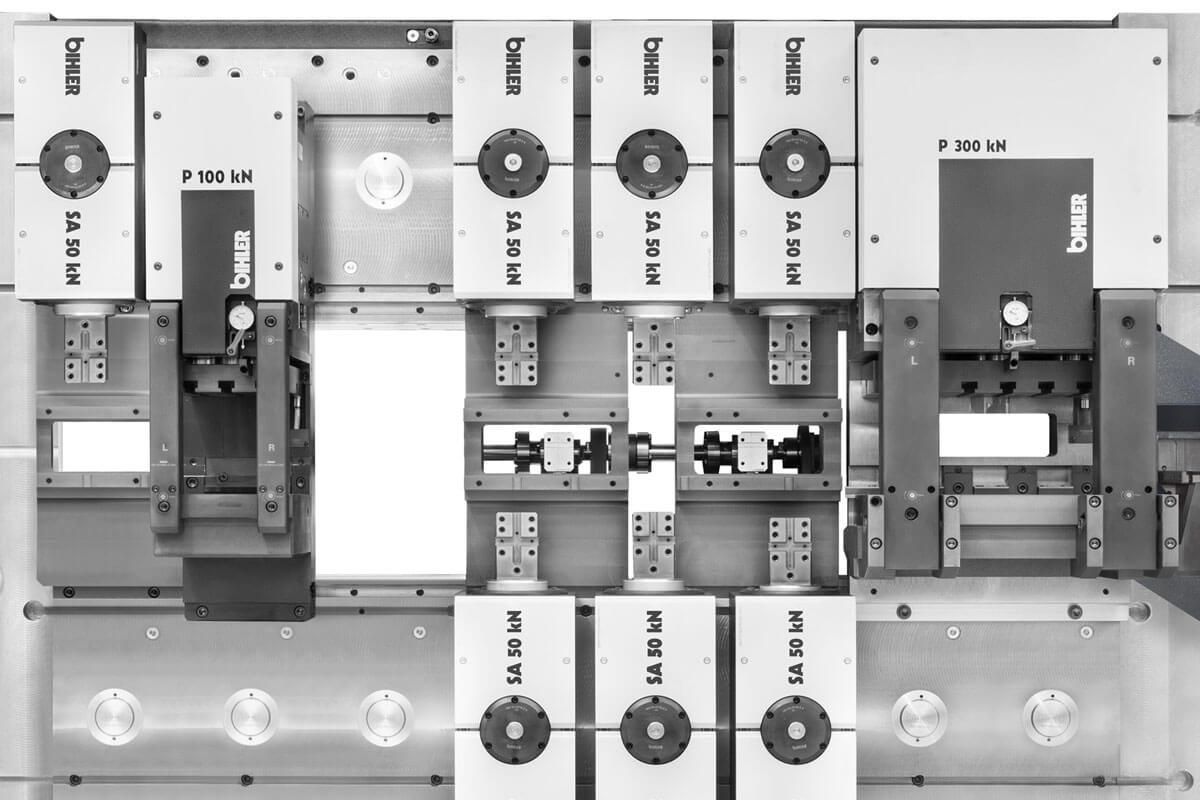

Conventional disk cam technology continues to offer outstanding advantages in the stamping and bending field and is consistently further developed at Otto Bihler Maschinenfabrik. One current example is the new processing center, the BZ2-S8. This embodies the latest generation of the proven series of manufacturing systems and offers numerous new features and functions. As a result, the BZ2-S8 is now able to achieve production speeds of up to 700 rpm. This is also possible thanks to the machine’s completely redesigned drive. Thus, compared to the predecessor model, the processing center no longer has a frequency-regulated three-phase motor but is instead driven exclusively by servomotors. The slide units have also been adapted to the high speeds and are now considerably more robust than before. The BZ2-S8 is again operated and controlled using the VC 1 controller.

Contact Us