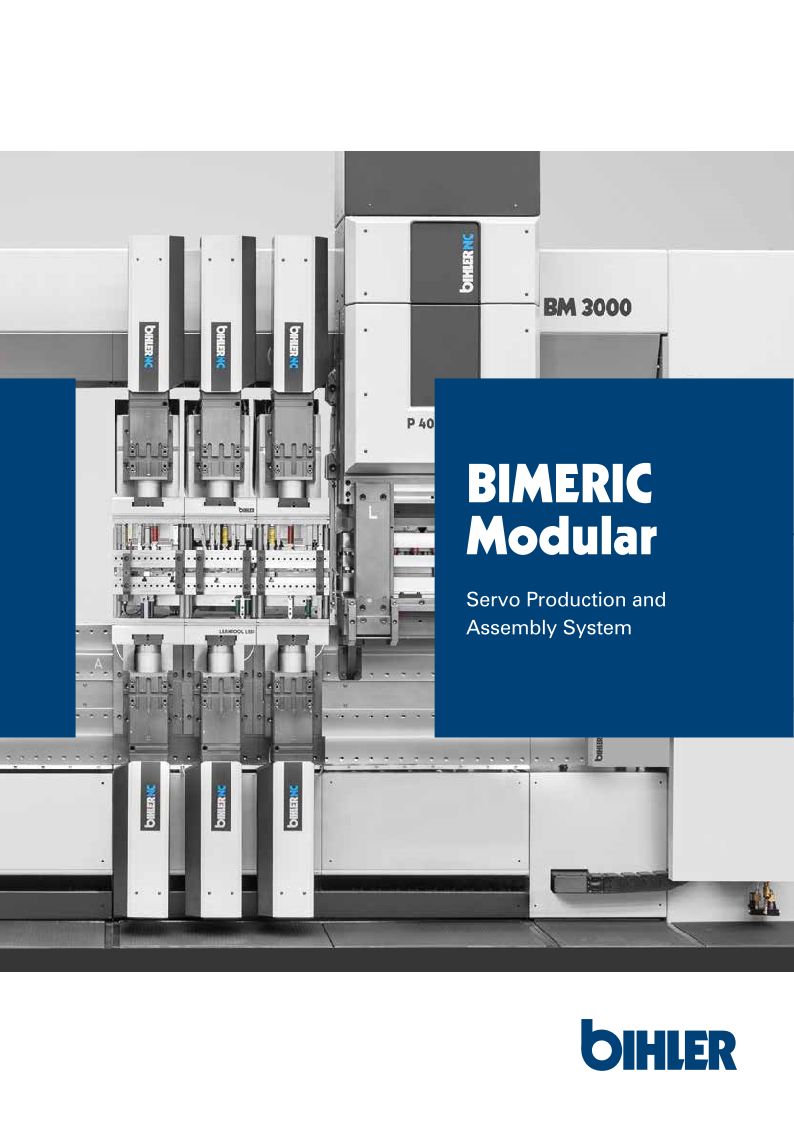

Modular, standardized servo production and assembly system for highly efficient component and assembly production

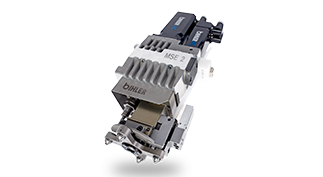

- Standardized, pre-mounted process modules for feeding, stamping and forming (designed for 80 mm strip width)

- PLUS-empty locations for further processing modules and individual units

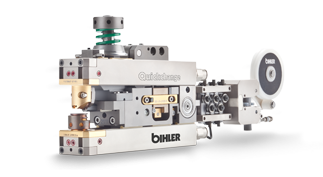

- Full compatibility with LEANTOOL linear system:

up to 70 % standard tool parts - Very fast and 100% reproducible setup of tool modules

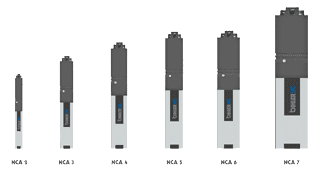

- Perfectly designed for small and medium batch sizes and large variant diversity

- Flexibly scalable for future tasks

PM400

PM400 EMR

EMR BM-L250

BM-L250