Request Electrical Manufacturing Automation Consulting Today

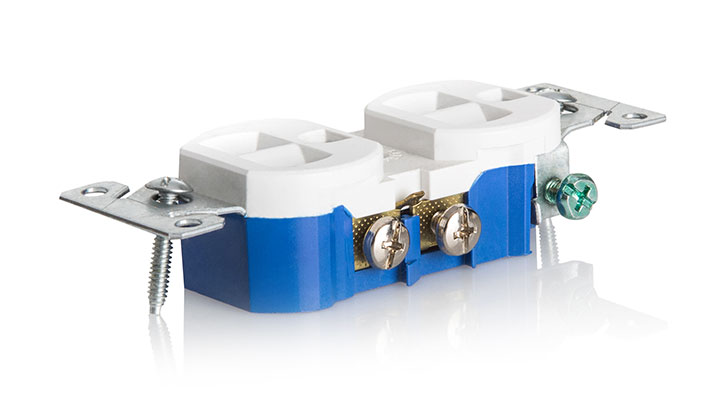

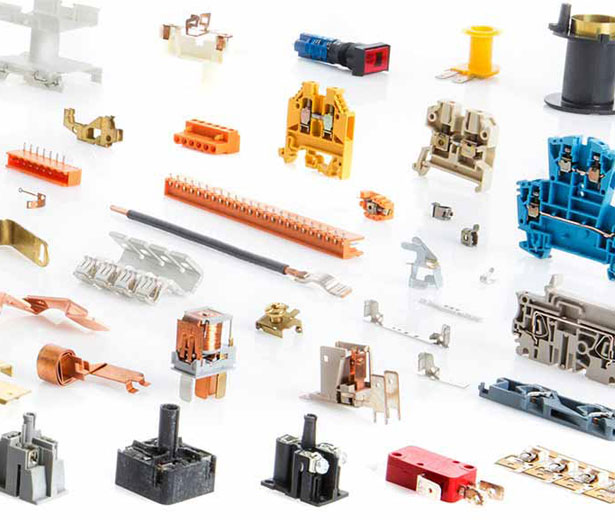

Bihler of America believes in the importance of quality electrical fabrication manufacturing equipment and well-trained staff who feel confident using those machines. Outside of offering the best electrical metal forming and stamping equipment, we also provide consultation services for our partners.

These consultations give users access to an expert equipment team who understands our machines and how to adjust them to provide the most accurate and personalized solutions. During a consultation, we will consider your facility’s applications and develop custom codes, allowing you to further streamline your operations.

Whether your goals focus on saving money or making more of it, Bihler’s tools and experience are your solution for better results and an enhanced bottom line. Contact us today to learn more about our machines or schedule a consultation.

Contact Us Today

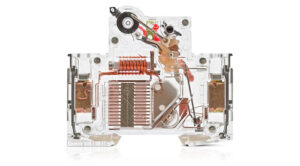

High-Current Contact Lamellae

High-Current Contact Lamellae