Simply Better Welding

For more than 50 years, we have been integrating welding processes in fully automated solutions. We have delivered thousands of welding controls and welding units in this period.

Our strengths are in the areas of:

- resistance butt welding, mash seam welding,

- projection welding, contact welding, precious metal welding,

- compacting strands, nut welding and soldering.

Intelligent welding control systems and highly flexible welding devices from Bihler guarantee maximum process reliability, high productivity and excellent welding quality. In the field of laser welding, we rely on the top quality of our technology partner TRUMPF.

Benefit from our wealth of experience in welding technology.

Resistance Welding Solutions

Resistance welding is cost-effective, but ensuring proper alignment and a strong bond requires precision. If your business utilizes worker-operated resistance welding processes, your employees must take time to achieve the necessary accuracy and quality while operating within the various OSHA regulations that ensure worker safety. You can increase efficiency and safety by automating resistance welding jobs at your facility.

At Bihler of America, we provide automated resistance welding machines for equipment manufacturers across industries. Browse our selection to outfit your facility with dependable automated resistance welding equipment.

Automated Resistance Welding Equipment From Bihler of America

Bihler Street Welding is an automated solution for resistance welding jobs. This resistance welding machine includes the VariControl VC 1 interface for users to program the system’s performance. With the press of a button, you can set your resistance welding machine to complete complex functions at an output speed that will keep your business on schedule.

We design our automated resistance welding machines to fuse metal when manufacturing components for various purposes:

- Welding automotive parts

- Building electronic components and assemblies

- Producing components for medical devices

- Fusing materials and developing building products

Resistance Welding Capabilities

Our resistance welding machines are capable of automating many of the techniques you utilize daily, including:

- Mash seam welding: Achieve strong lap joints for components containing or sealing fluids and gases. Mash seam welding applies some heat but primarily relies on pressure.

- Flash butt welding: Fuse metal by generating resistance heat from the materials themselves. Flash butt welding is ideal when welding thick substrates, such as pipes, chains and rails.

- Projection welding: Join metal parts by applying pressure and an electrical current at a fusion point with maximum surface area. Projection welding is ideal for fusing fasteners to sheet metal plates or building electrical components like grilles and condensers.

Benefits of Automating Resistance Welding Processes

Automating your resistance welding processes with a Bihler machine will provide various benefits that increase revenue while limiting expenses:

- Speed: Automation expedites welding processes. We produce numerous resistance welding machines offering a wide range of welds per minute so you can choose the device that best fits your production needs.

- Precision: You can program your Bilhler resistance welding machine to perform the exact type of weld you need.

- Accuracy: Automation elevates accuracy to reduce mistakes and maximize production speed. These advantages apply to even the most precise welding jobs.

- Integration: Our resistance welding machines feature modular designs that will accept your existing progressive dies.

- Safety: Resistance welding generates heat, electricity and sparks that can harm your employees. Automate resistance welding to reduce workplace incidents.

- Productivity: When you automate monotonous, time-consuming tasks like resistance welding, your welders can focus on the tasks that require greater care.

Frequently Asked Questions

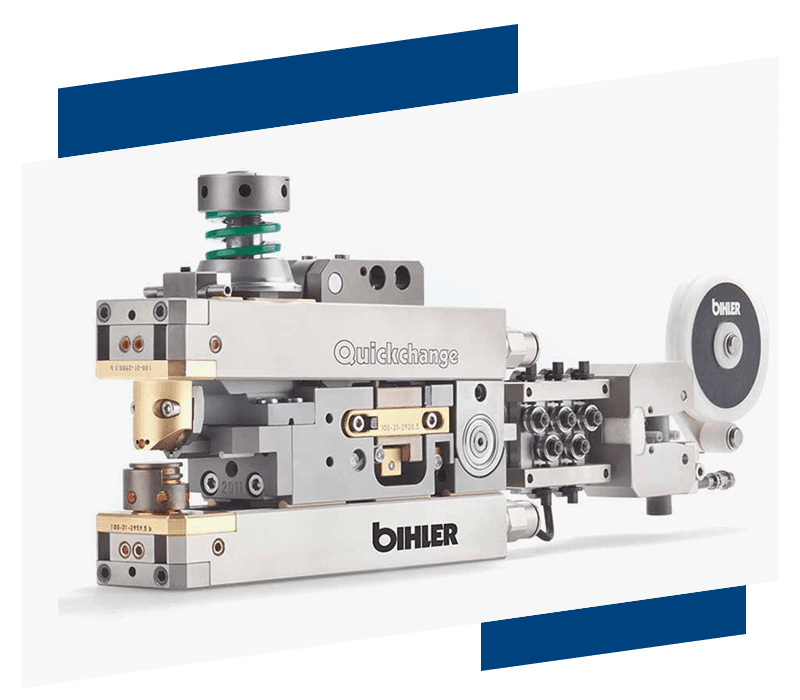

Resistance welding is when parts are pressed together by electrode force; electric resistance heating is created at the contact surface between the parts by passing an electric current over the electrodes. Bihler’s resistance welding units are engineered for high-speed, mass production of metal components, achieving up to 800 welds/min. Thanks to the Quickchange system, retooling time is reduced by over 90% compared to traditional units, ensuring maximum efficiency. Find out more about Bihler’s contact welding capabilities.

Bihler’s resistance welding units are capable of butt welding, mash seam welding, projection welding, contact welding, resistance soldering, compacting strands, and nut welding. Find out more about Bihler’s contact welding capabilities.

Key advantages of implementing a Bihler welding system onto a Bihler machine include eliminating an extra step into production processing, increased speed, precision, high-strength welds, and the ability to weld different types of materials. Bihler takes it a step further with automated, high-performance systems designed to enhance productivity. Our welding technology integrates advanced automation, ensuring seamless, consistent, and high-throughput processes for scalable production and improved reliability. Contact Bihler to see what advantage Bihler can offer your contact welding projects: (908)213-9001

The key industries that can take advantage of an integrated welding system on a machine to reduce a secondary process would be electrical component manufacturers looking to make wiring device’s, circuit breaker switches, thermal assemblies, and electrical contact parts. Other industries include automotive, medical and aerospace. Contact Bihler today to see which type of welding is right for your project: (908)213-9001

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin