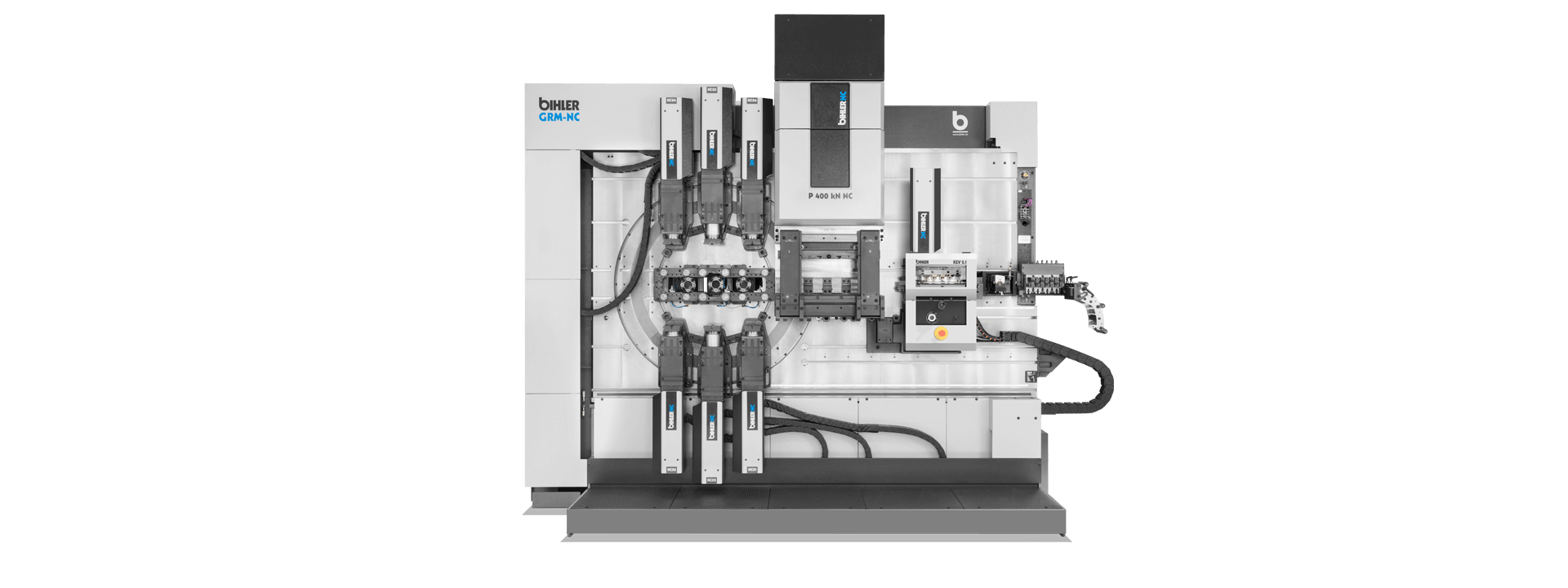

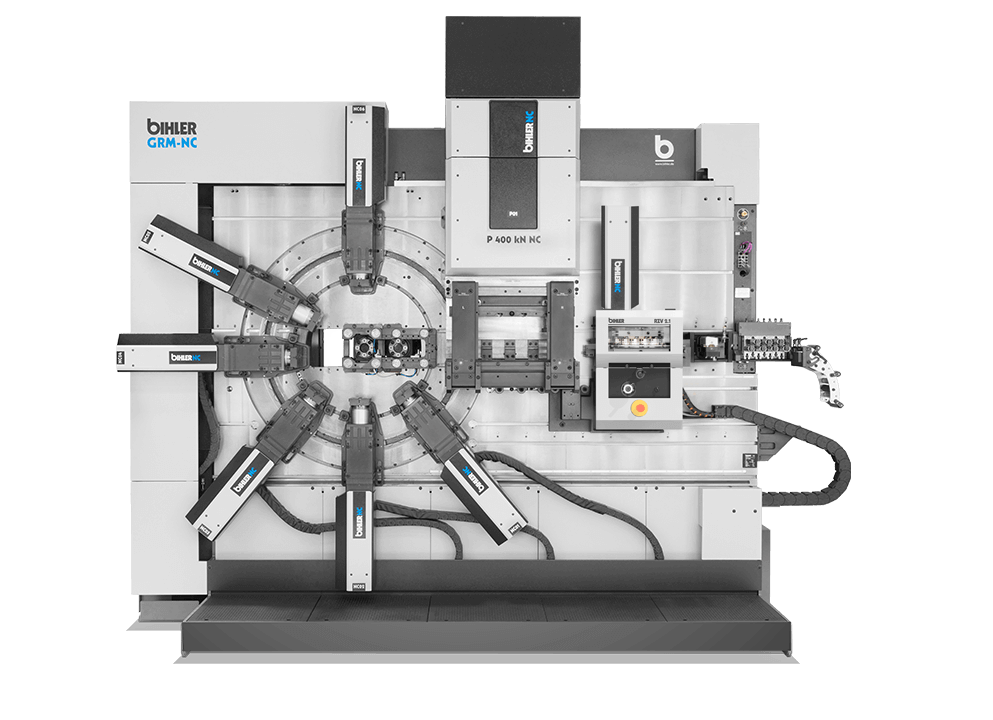

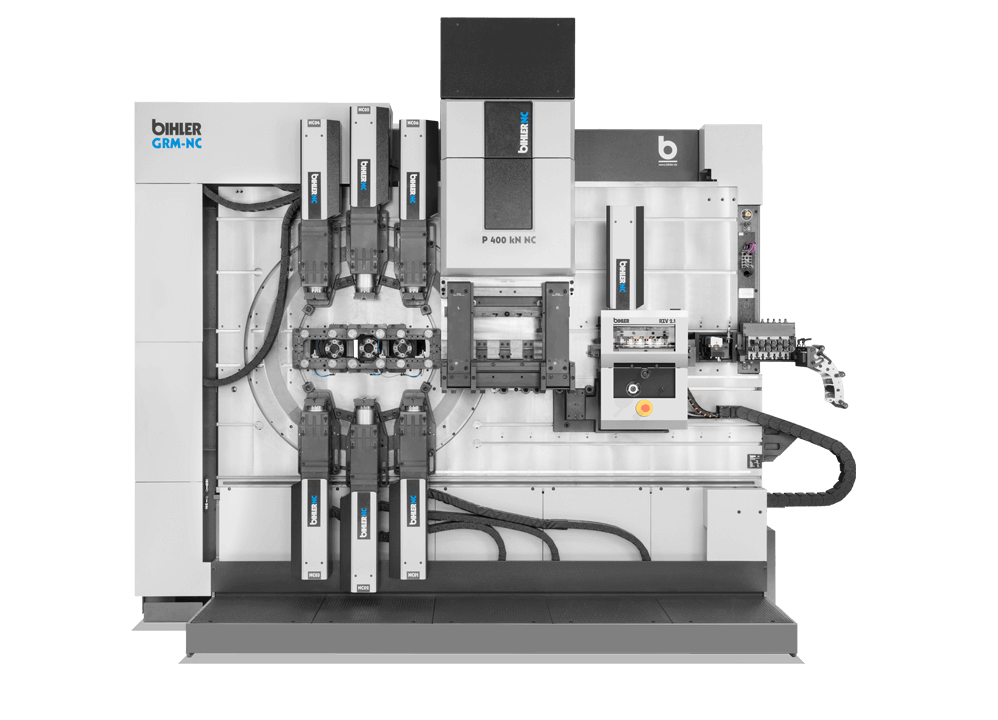

High performance servo machining system for stamped and formed parts, wire parts as well as progressive components in small and medium batch sizes

- High production speeds up to 240 1/min.

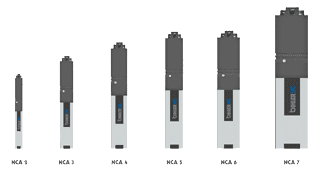

- Standardized machine platform for radial and linear LEANTOOL system

- Process lengths of over 2,000 can be realized in linear production with three bending modules and two servo presses

- 100% reproducibility and rapid response to short-term customer requests

- Full tool compatibility with GRM series

- Decisive increase in output (more than 300% possible*)

- Extremely short set-up times (up to 10 times faster*)

*When moving tools from mechanical GRM machines to GRM-NC

Production of “Technical Springs”