More Economical Large-Scale Production

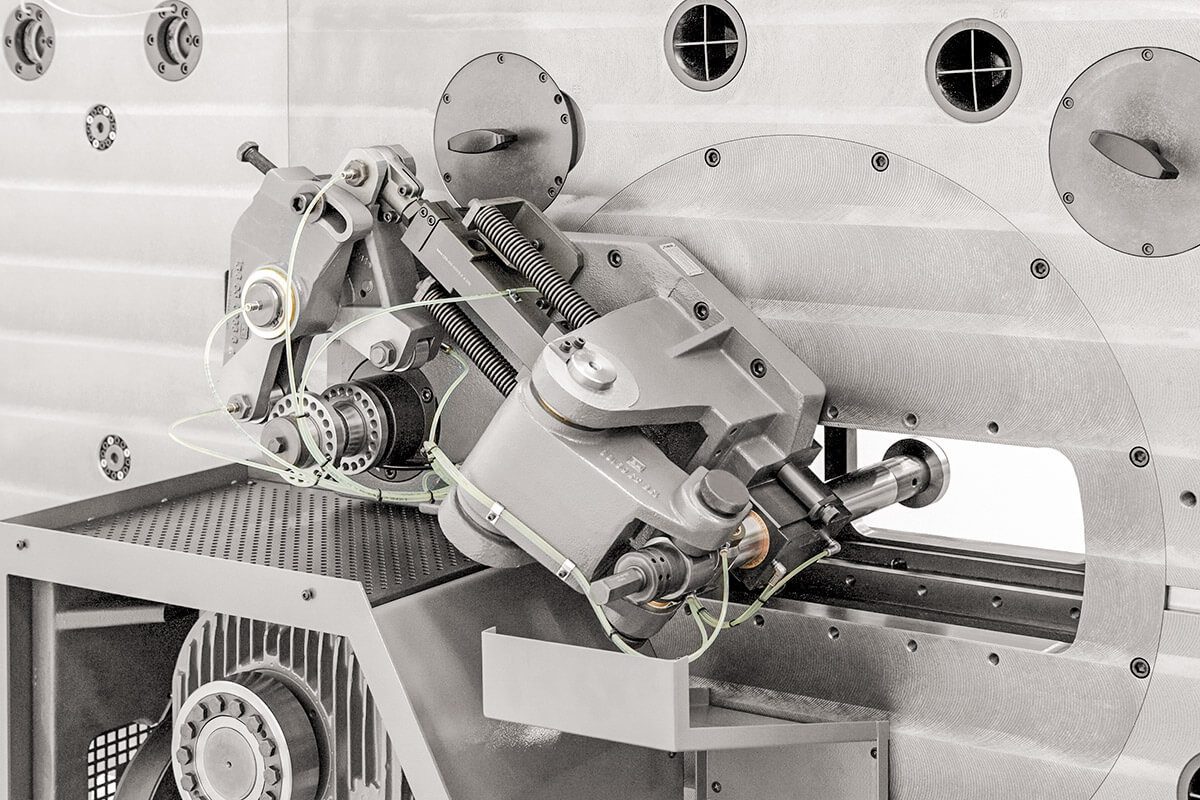

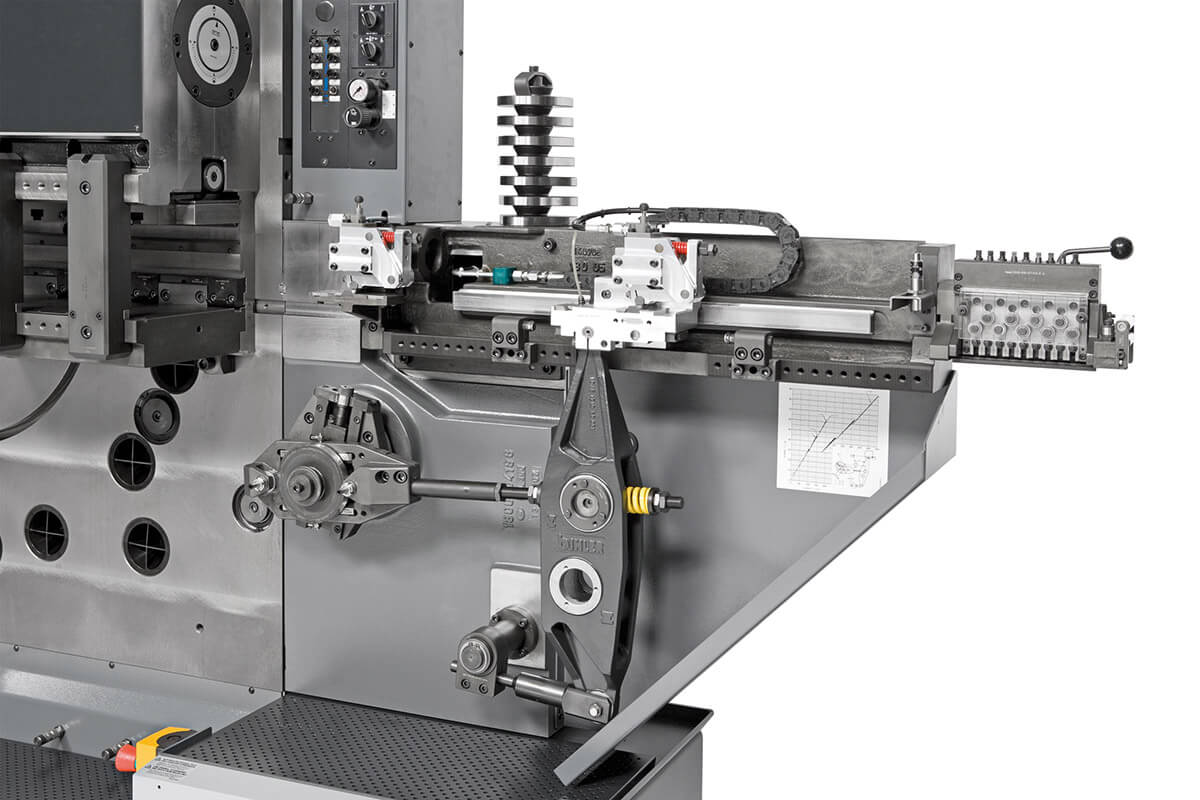

Produce stamped and formed parts in large batches with even higher productivity. Benefit from the high performance and excellent manufacturing quality of the universal GRM machines. These mechanical multi-slide machines offer cost-effective assembly production with their large processing space for stamping, bending, assembling, welding, thread forming, screw insertion etc.

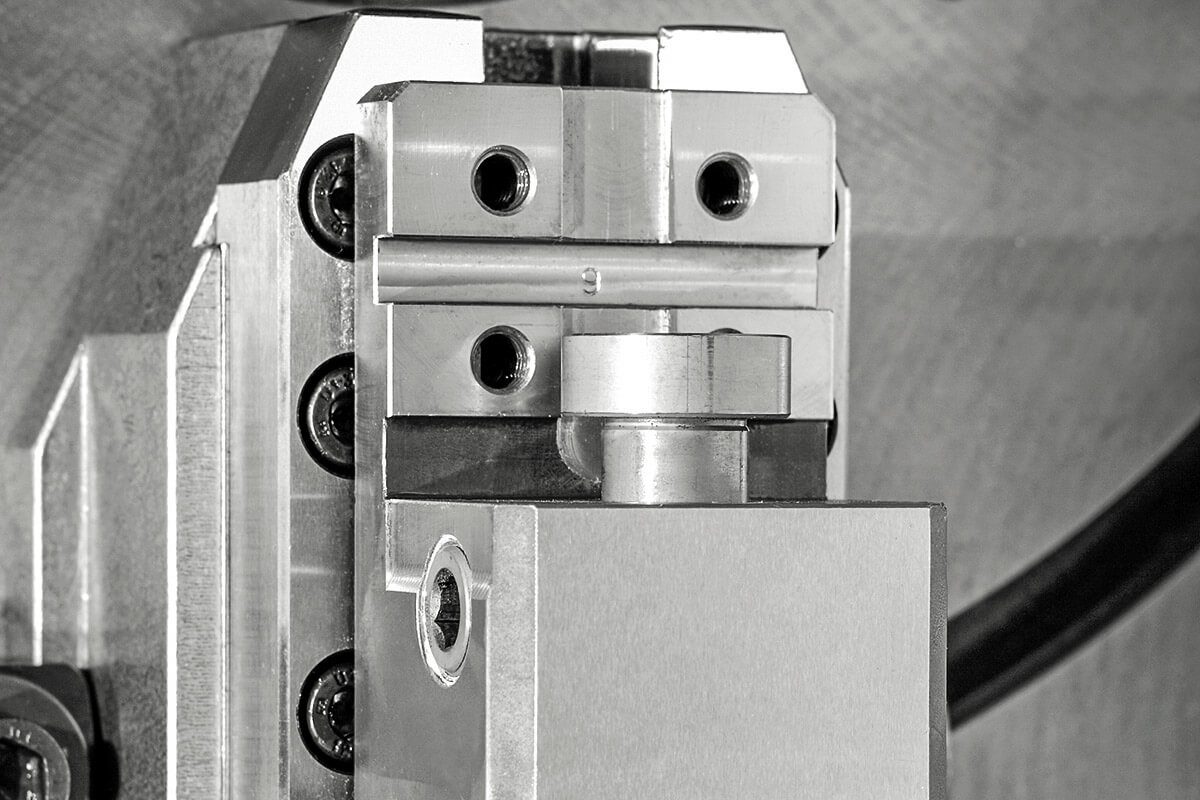

Innovative quick-change systems and the excellent accessibility to all processing stations guarantee minimum setup and tool changing times. Equipped with the latest control technology, you can operate the GRM machines with ease.

Machine Details

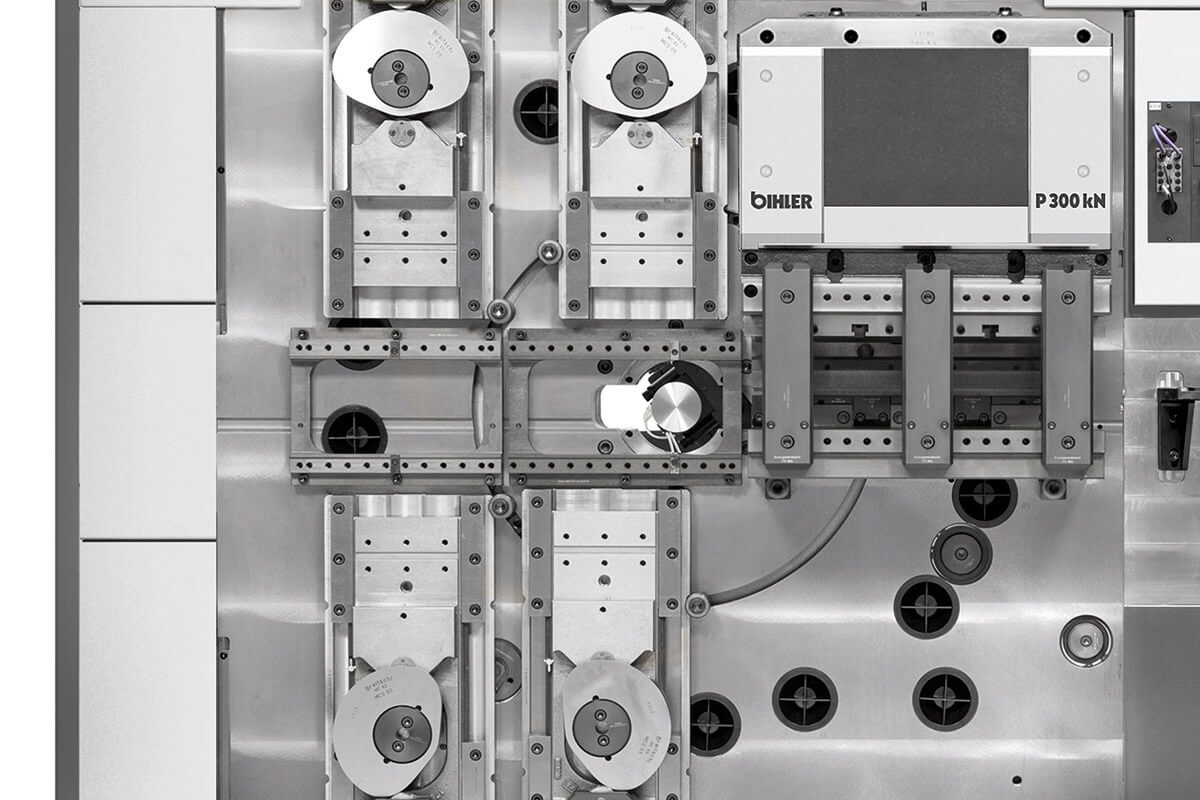

Universal, powerful machine system for mass production of larger stamped and formed parts and sub-assemblies

- High production speeds of up to 250/min

- Perfectly designed for radial and linear processing concepts

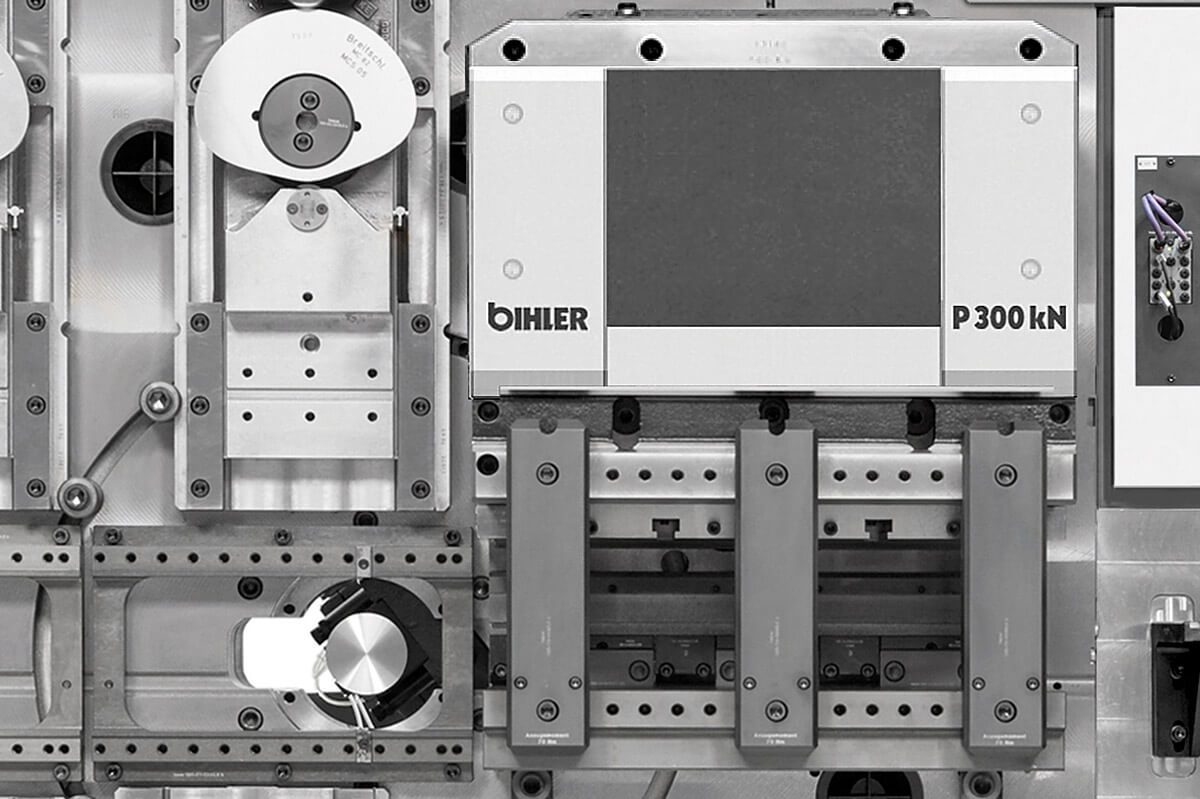

- Stable 300 kN two-point eccentric press with large installation capacity

- Large central aperture for variable central mandrel movements

- Comprehensive control and monitoring functions

- Easy to use VC 1E control with 15″ touch screen

| Stroke rate | Variable drive control from 5 to max. 250 1/min. |

| Max. nominal forming capacity 90 kN, max. stroke 95 mm | |

| Mech. feed: max. 500 mm, with feed cycle reduction, servo feed: any feed length (as option) | |

| Material | Max. strip thickness: 6 mm, max. strip width 80 mm, max. wire Ø 6 mm (depending on material and process) |

| Width 3,140 mm x depth 1,595 mm x height 2,220 mm | |

| Weight | Approx. 3,000 kg (without tooling) |

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin