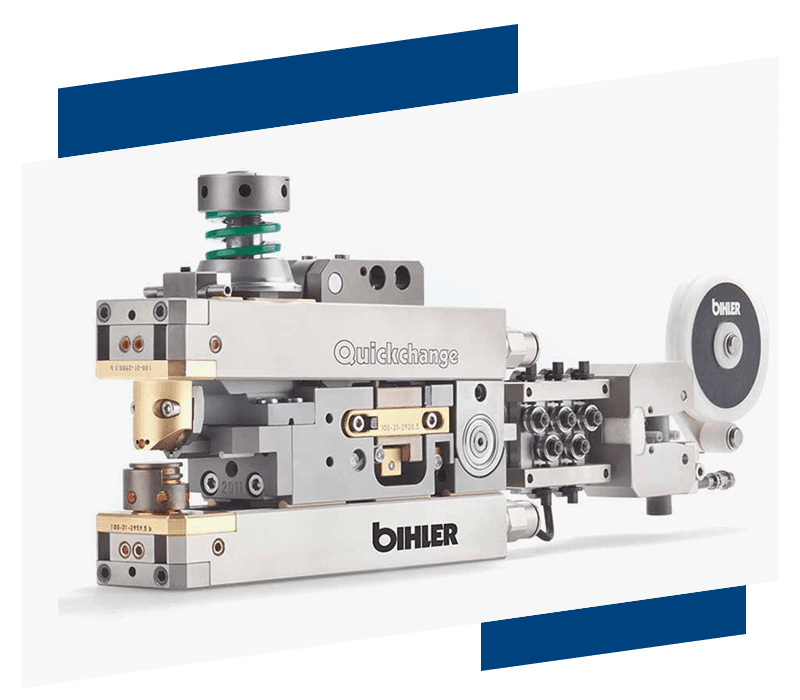

Metal Forming Solutions

In the metal forming process, semi-finished products like metal strips or wires are precisely shaped using radial or linear bending tools within a stamping and forming machine. Every movement of the bending tool—stroke, duration, and speed—is fully customizable via cams or NC units, allowing for optimized machine speeds and individual adjustments for each processing station.

This advanced approach ensures reliable and precise workpiece shaping, combining optimized motion sequences with material-friendly processes that maintain the integrity of the metal. The result is high precision, exceptional repeatability, and consistent quality.

With durable tools and extended tool life, this process delivers cost-efficient, consistent production tailored to meet a variety of manufacturing needs. Experience superior performance and reliability with innovative metal forming solutions designed to elevate your production capabilities.

Automated Machines for Metal Forming Applications

Automated metal forming tools empower manufacturers to work faster and smarter. At Bihler, we produce various types of metal forming machines, each compatible with our VariControl VC 1 programmable console. Our experts can help you find, tailor and utilize the right metal forming machine for your manufacturing process. Options include:

- Servo stamping and forming machines: Choose an automated machine with a servo motor that facilitates acute control over all roll forming and stamping functions.

- Servo presses: Choose a servo motor-powered metal forming machine that presses sheet metal into the size and shape programmed through its automation interface.

- Stamping and forming machines: Produce various stamped and formed parts with an automated machine that matches your ideal production speed.

- Multicenters: Outfit your facility with a multifunctional machine system capable of automating numerous metal processing techniques such as tapping, screw insertion, stamping and forming.

Benefits of Automated Precision Metal Forming Equipment

Manufacturing companies strive to improve production efficiency while maintaining the consistent quality that customers expect. Automated metal forming machines from Bihler offer numerous advantages to help you achieve your goals:

- Precision: Automation allows manufacturers to form and replicate detailed metal components according to exact specifications.

- Efficiency: Automated machines work fast and require minimal downtime, resulting in high production efficiency when manufacturing at any scale.

- Accuracy: Automating metal forming processes eliminates human error, thereby reducing the frequency of mistakes, preventing waste and unlocking enhanced control over intricate details.

- Savings: Manufacturers that automate demanding metal forming processes save by reducing mistakes and downtime while allocating labor to tasks that require closer attention from human workers.

- Support: When you choose automated precision metal forming equipment from Bihler, our representatives will help you set up and optimize your machine at any point during its life span.

Frequently Asked Questions

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin