Electrical Manufacturing Solutions

Electrical manufacturing demands precision, focus, and top-tier equipment to meet the highest standards. Your customers expect products that are safe, functional, and exact, and the Bihler Group of Companies empowers you to consistently exceed those expectations.

Our cutting-edge systems provide custom manufacturing solutions for metal forming, stamping, and a variety of operations in your electrical plant. With Bihler, you can efficiently produce even the smallest and most complex parts, all while enhancing safety and operational efficiency.

Trust Bihler to elevate your production capabilities and deliver quality that inspires confidence.

Producing Components Designed for Safety

Even the most careful electricians face challenging situations. An old wire or faulty mechanism can make or break an entire electrical system, and when not handled properly, they can pose dangers for anyone within the vicinity.

Workers in the electrical industry depend on manufacturers to produce high-quality, dependable components. Bihler machines have helped construct this type of equipment for decades, giving some of the most trusted names in the industry the solutions they need to make:

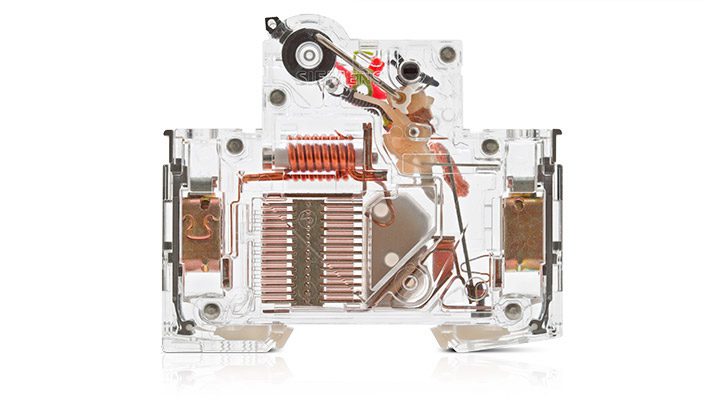

Trip-Free Circuit Breakers

A breaker that short-circuits must turn off immediately to prevent widespread outages or damage. Many of our stamping and forming machines can produce reliable, trip-free mechanisms at rates over 300 parts per minute, so you can outfit every circuit with overload-protecting breakers.

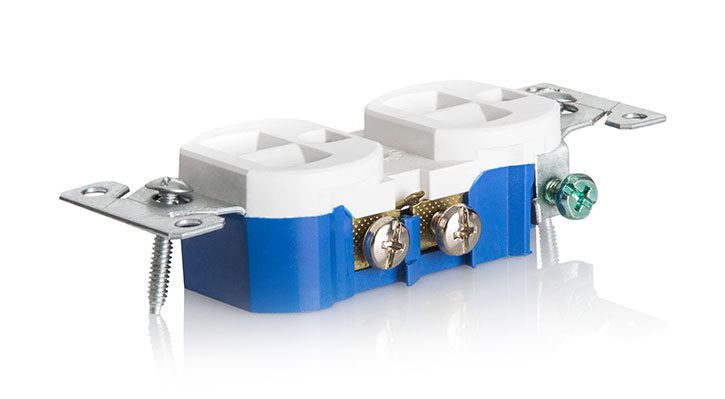

Safe Electrical Sockets

Electrical sockets must be carefully constructed to work correctly and safely. Bihler electrical fabrication manufacturing equipment produces components to your exact specifications. Manufacture hundreds of sockets in minutes with more than 80 safe product varients when using Bihler machines.

Secure Grounding Parts

Grounding keeps your systems safe from overload. As the technology field makes rapid advancements, the need for high-quality grounding connectors grows with it. Bihler stamping and forming machines can produce hundreds of grounding connectors per minute. Our systems can easily output large grounding components for large commercial and industrial jobs or smaller ones for home and personal use.

Purpose-Built Electrical Metal Forming & Stamping Equipment

Bihler manufactures easy-to-use standard equipment and offers options that tailor those machines to specific production requirements. Our industry-leading systems meet rigorous standards for accuracy and efficiency. We understand that even the most intricate products must meet stringent standards for precision, and our electrical manufacturing equipment delivers those components to your exact specifications.

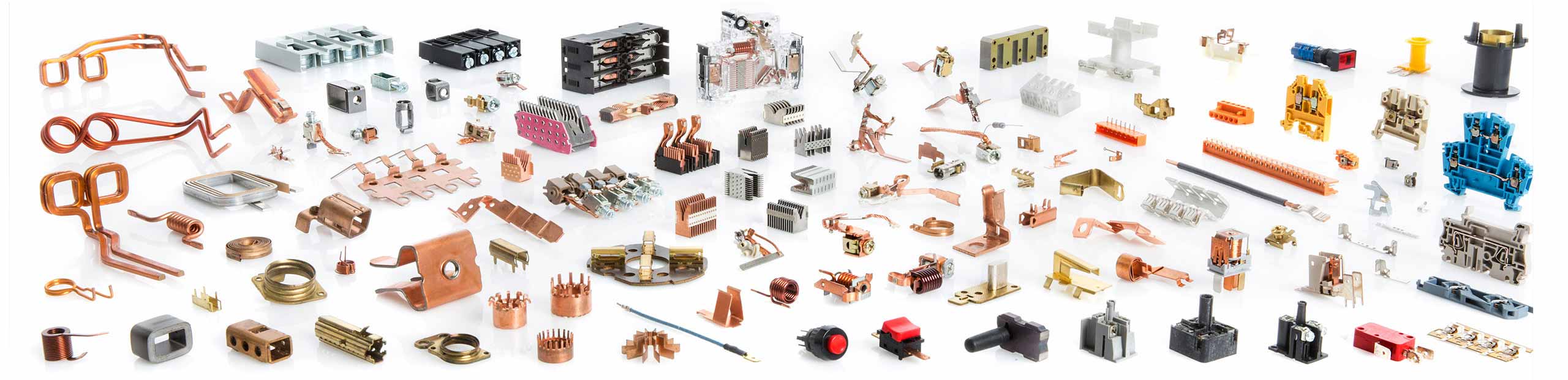

Bihler Machine-Made Electrical Components

Circuit Breakers and Components

Circuit Breakers and Components

A Bihler GRM-80P stamping and forming machine can manufacture the free-moving part of a circuit breaker at a rate of 200 parts per minute. Additional Bihler production systems can match this rate of productivity for a fully assembled circuit breaker.

High-Current Contact Lamellae

High-Current Contact Lamellae

Developed for high-current contacts in transformers, switchgear cabinets and circuit breakers, this component consists of a sprung stainless steel carrier strip with riveted lamellar bands. A Bihler production & assembly system paired with a radial gripper feed and welding system can output 100 lamellae per minute, cutting, bending, stamping, contact welding, and removing excess waste material in a single, end-to-end process.

Wire Devices

Wire Devices

Bihler machines have been producing components of wire devices for more than three decades. Metal parts are produce on a GRM 80 stamping and forming machine and complemented by servo modules that weld, thread cut, insert screws, feed, test and mark the socket. An active assembly line can produce 120 finished and packaged sockets per minute.

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin