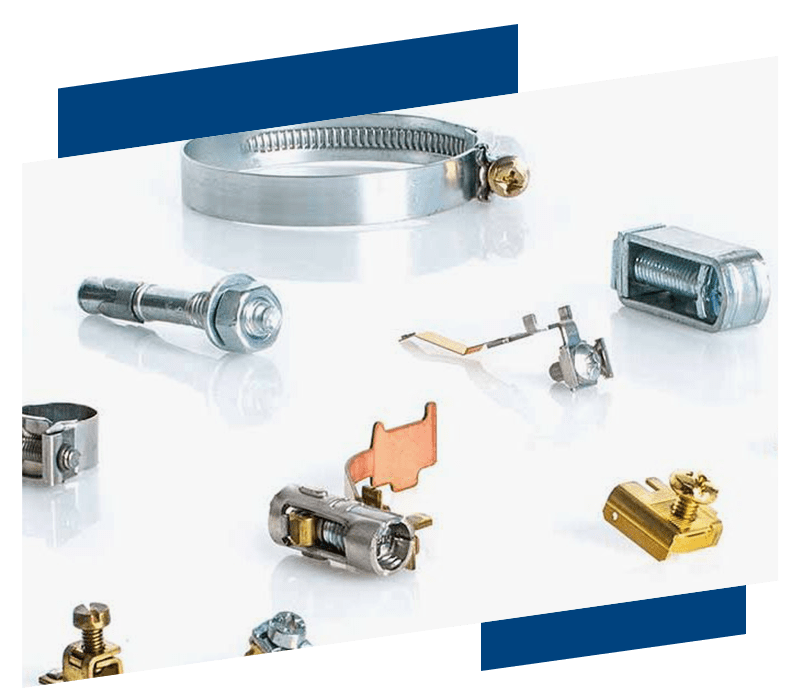

Fastening Solutions

Bihler of America produces manufacturing machines that fasten screws, bolts and rivets. Our technology boosts fastening speed and accuracy when manufacturing components for automotive parts, electrical components, industrial machinery, electric vehicles and medical equipment. Each machine has automation capabilities you can program through its VariControl VC 1 console. Request a quote for automated fastening solutions from Bihler today.

Automated Fastening Equipment for Manufacturing Applications

Your customers rely on you to deliver durable, dependable components and products. Secure fastening is key to ensuring any product’s longevity and performance. Our automated riveting solutions provide fast, reliable assembly, tightly binding components to uphold quality and durability. With our technology, you can enhance your manufacturing processes and strengthen customer trust through robust, steadfast results.

Bihler fastening equipment expedites screw, rivet and bolt insertion through servomotor-powered machinery. Our machines complete up to 180 connections per minute. Choose the optimal type of screw and thread for the application, and allow the fastening machine to complete the task.

Each Bihler fastening machine completes all relevant processes, including feeding, separating, positioning and inserting screws. You can also program the device for two-side fastening, hole cleaning and sealant application. Select models offer spring coiling capabilities. Use the VariControl VC 1 interface to specify the function, torque and speed.

Bihler MSE 2

The Bihler MSE 2 series is a line of premier automated fastening machines for mass production. Each device offers high cycle rates to help your business manage projects of any size. The compact frame makes it possible to fit an MSE 2 unit or multiple units into any assembly line. MSE 2 machines are compatible with many standard screws and threads up to M8. A rapid changeover system enables fast retooling between screws.

MSE 2 units offer unique automation capabilities through a VariControl VC 1 console. Access acute programming for details like screw depth, rotation angle and pitch. Set the torque anywhere from 0.1 to 2 newton meters (nm) to achieve the ideal clamp force for the application.

The MSE 2 line has two editions — standalone and sub-system. The standalone MSE unit completes 140 fastenings per minute, while the sub-system completes 180 fastenings per minute. Each unit offers a feed speed of 424 millimeters per second and a 50-millimeter stroke.

Benefits of Automating Fastening Processes

Automated screw fastening machines offer numerous advantages in manufacturing settings. Implement a Bihler device for:

- Speed and efficiency: Achieve higher output during fastening and preparation tasks while reducing labor expenses.

- Productivity: Delegate time-consuming fastening tasks to an automated machine so your staff can focus on high-value manufacturing activities.

- Worker safety: Reduce strain and injury by relieving employees of repetitive fastening tasks.

- Mass production: Increase production by using a fastening machine offering cycle rates of up to 180 per minute.

- Precision: Program the optimal torque, depth and pitch for the bolted joints you need to form.

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin