Simply More Efficient Production

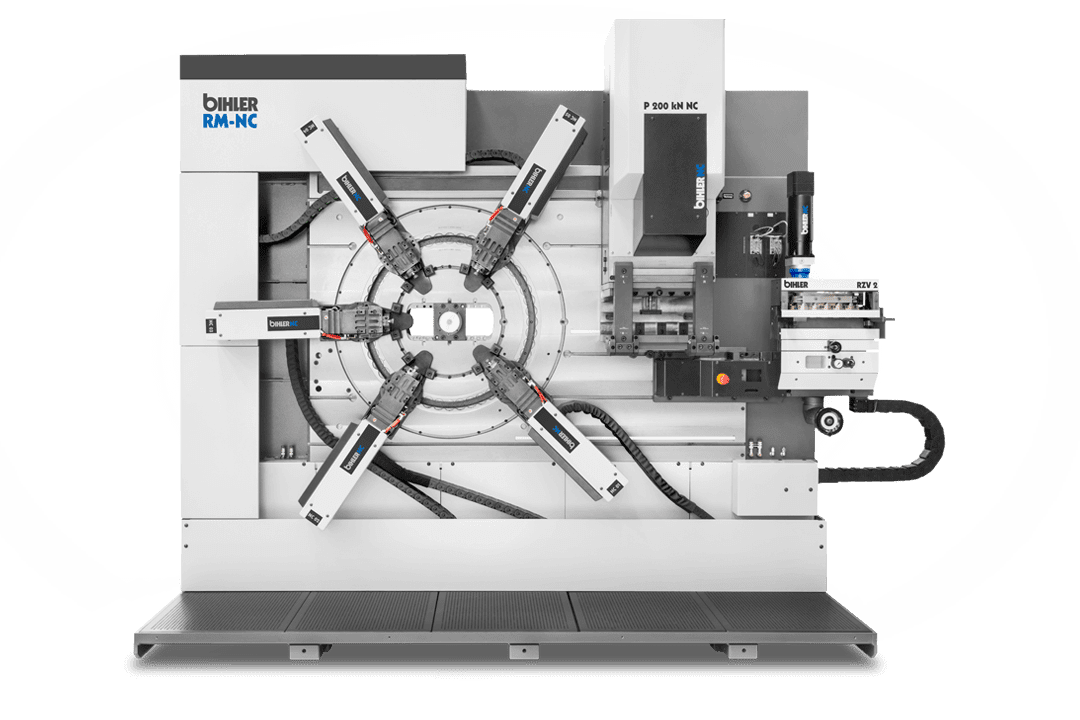

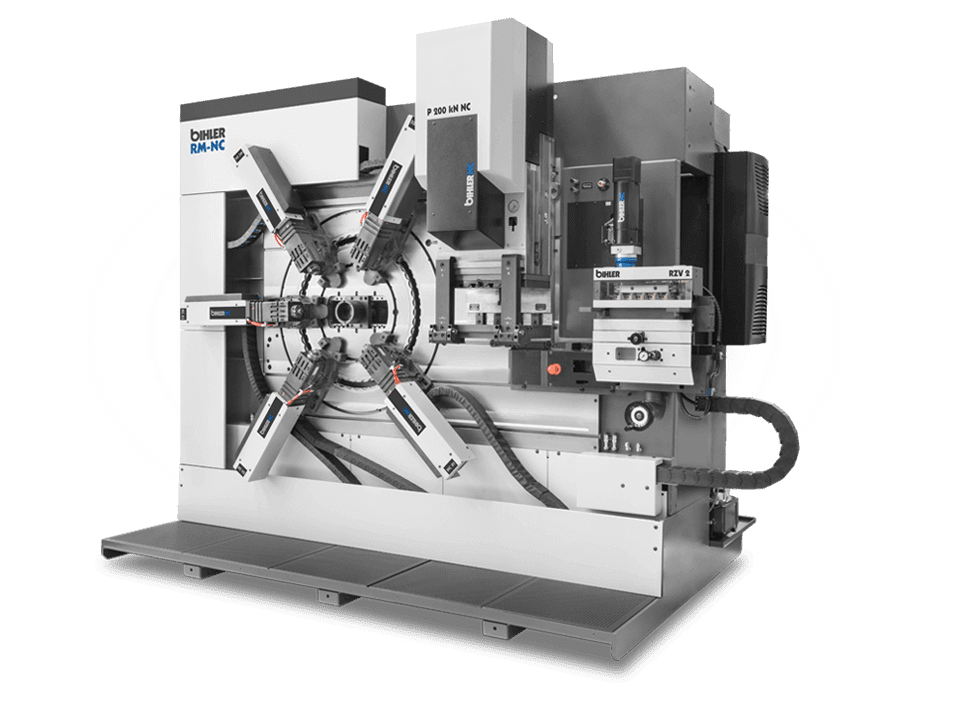

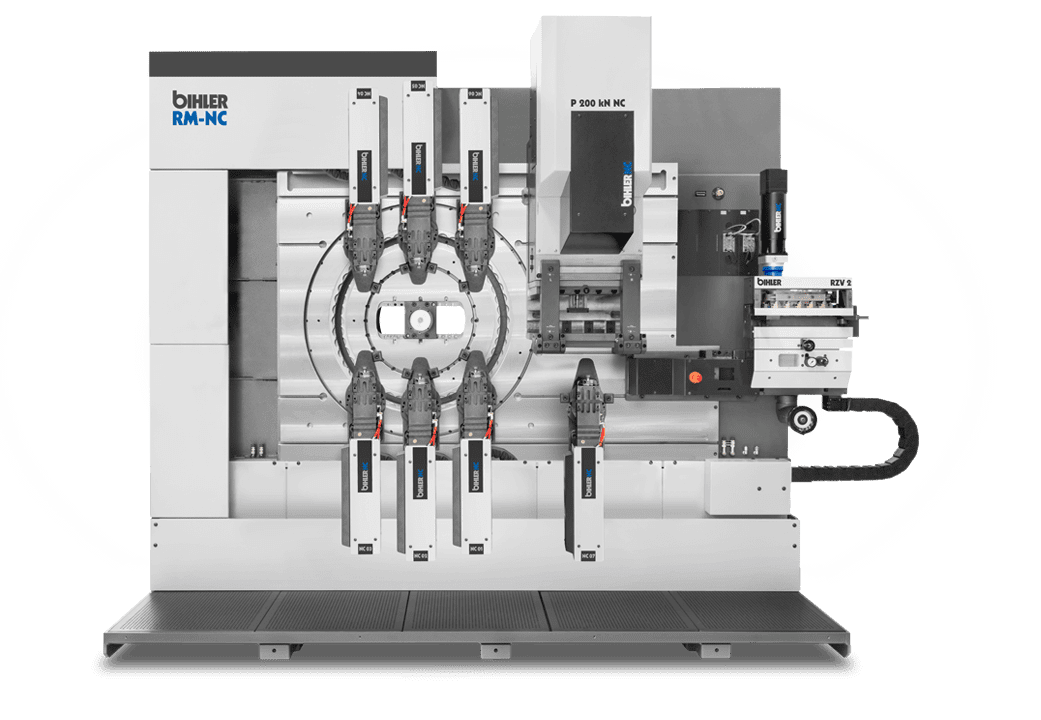

The servo-controlled RM-NC and GRM-NC stamping, forming, multi-slide machines enable the production of traditional stamped and formed parts from wire and strip, as well as advanced progressive components, with exceptional flexibility and productivity. These systems offer rapid tool changeovers and efficient handling of even the smallest batch sizes, ensuring superior product quality.

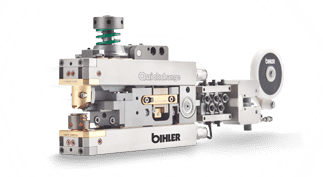

When integrated with the LEANTOOL system, the implementation of radial and linear bending tools becomes significantly more efficient, reducing complexity, cost, and time. With full compatibility with RM and GRM machines, existing tools can be easily adapted and optimized for servo machines in a remarkably short timeframe.

Key benefits include up to an 80% reduction in setup time and a substantial increase in production output.

Machine Details

Powerful servo machining system for efficient production of stamped and formed parts, as well as wire parts, in small and medium batch sizes

- High production speeds up to 300 1/min.

- Standardized machine platform for radial LEANTOOL system

- 100% reproducibility and fine adjustment at the push of a button

- Rapid response to short-term customer requests

- Full tool compatibility with RM series and FINZER machines (ZUBHS 100/200, ZUB 200/220/250)

- Decisive increase in output (more than 300% possible*)

- Extremely short set-up times (up to 10 times faster*)

*When moving tools from mechanical RM / Finzer machines to RM-NC

Production of “compression and tension springs”

| Stroke | |

| Max. nominal forming capacity 20 kN, max. stroke 120 mm | |

| Any feed length | |

| Material | Max. strip thickness: 4 mm, max. strip width 80 mm, max. wire Ø 4 mm (depending on material and process) |

| Width 3,050 mm x depth 1,820 mm x height 2,600 mm | |

| Weight | Approx. 6,000 kg (without tooling) |

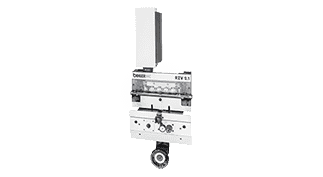

LEANTOOL Radial/Linear |

Brochure RM-NC / GRM-NC |

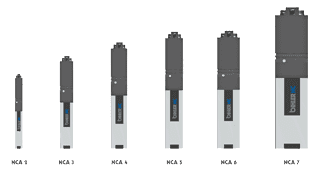

Modules

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin