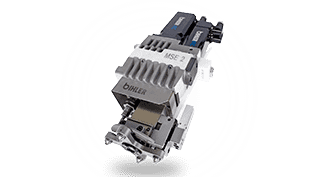

Precise Screw Fastening in Automated Mass Production

A wide range of screws can be inserted during component assembly, and are used to connect various elements of complex stamped, formed parts. To enable secure screw connections for thin sheet metal elements, the number of thread turns can be increased by extruding a collar. The servo-controlled MSE screw unit used with stamping and forming machines is designed for mass production with high cycle rates.

In combination with thread forming units, complete solutions can be implemented on stamping and forming machines. The screw unit performs all process-relevant steps, such as feeding, separating, positioning and screw insertion, with subsequent tightening to a specified torque.

Further advantages of the MSE:

- High cycle rates up to 180 connection operations/min.

- Universally applicable for various types of screws and threads due to free programming of all process-relevant parameters

- Special version can also be used for spring coiling

Modules

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin