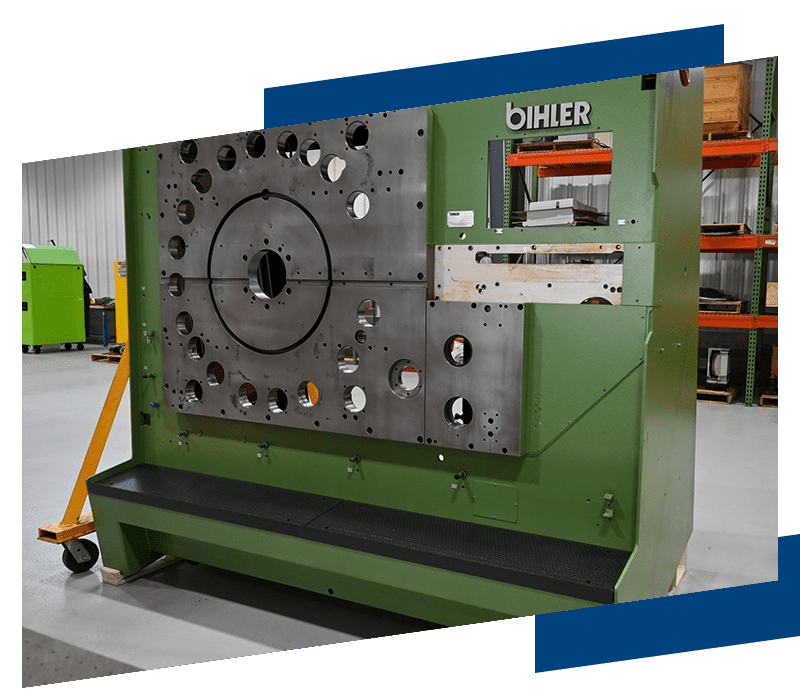

Reconditioned Bihler Machines – A Cost-Efficient Option

Maximize your investment with reconditioned Bihler machines, the perfect blend of reliability, precision, and savings. Whether you purchase a reconditioned machine or opt to have your existing Bihler machine overhauled, you’ll benefit from significant cost savings without compromising on performance.

For over 60 years, Bihler stamping and forming machines have earned a reputation for their unmatched reliability and durability. To ensure this legacy continues, we give our used machines a complete makeover, integrating the latest technology from our new models. The result is a cost-efficient machine with enhanced performance, improved precision, and the trusted Bihler quality you can rely on for years to come.

Here are just some of the benefits of these upgrades:

- Machine performance and accuracy are restored

- Mechanical and electrical systems are overhauled (Partial reconditioning is available, even on-site)

- Reconditioning is done to the very highest quality standards by Bihler experts

- Only Bihler original spare parts are used

- Machines are fitted with the latest Bihler VC 1E controller technology

- Start-up is done on your premises

- Machines are CE compliant, with optional full enclosure providing noise and operator protection

- Excellent price-performance ratio

- 12-month manufacturer’s warranty

- Customized support: fast spare parts service, comprehensive support and training, maintenance and repair service

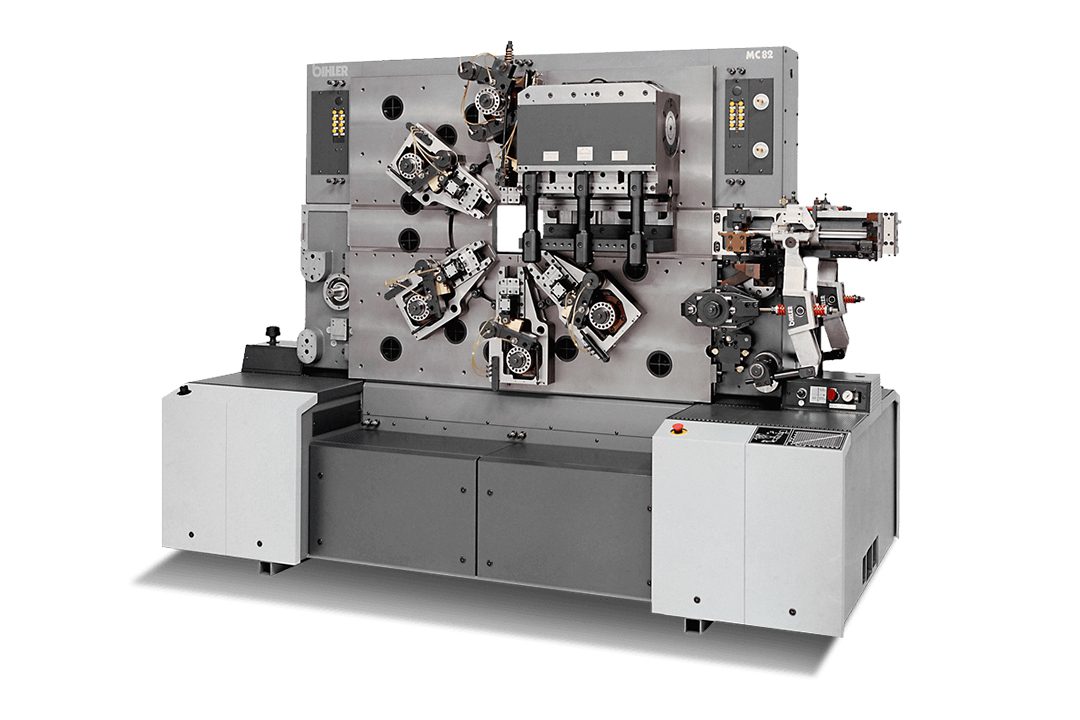

Complete reconditioning includes:

- Dismantling

- Full cleaning

- Sandblasting and priming

- New pipe work and wiring

- Reconditioning of all modules – feed, press, slide, central mandrel, etc.

- Assembly of drive unit

- Repainting

- Final assembly of machine and wiring

- Test run, and machine acceptance

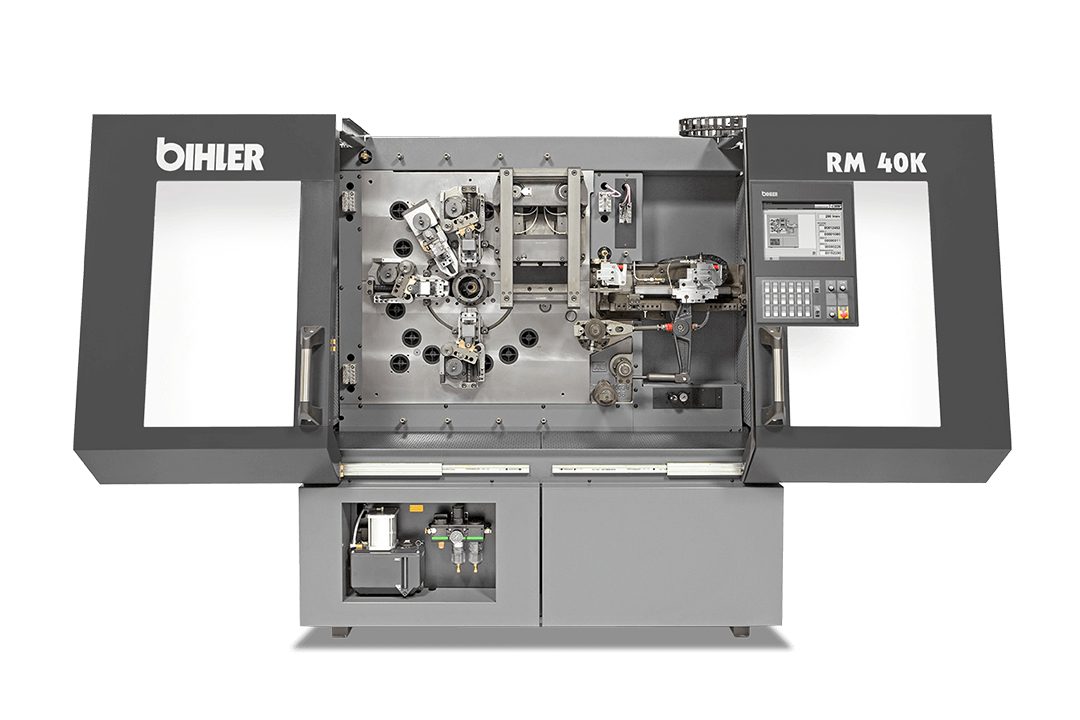

Leading-Edge Control Technology

The Bihler process control VariControl VC 1E improves the performance of your used machine, offering user-friendly operation and programming of individual input and output modules, via the 15 TFT touchscreen and other operating controls.

The VC 1E can control up to 6 NC axes. If required, the control unit can be expanded by a maximum of 16 analog measuring channels, enabling you to access new production potential, and to increase process reliability significantly.

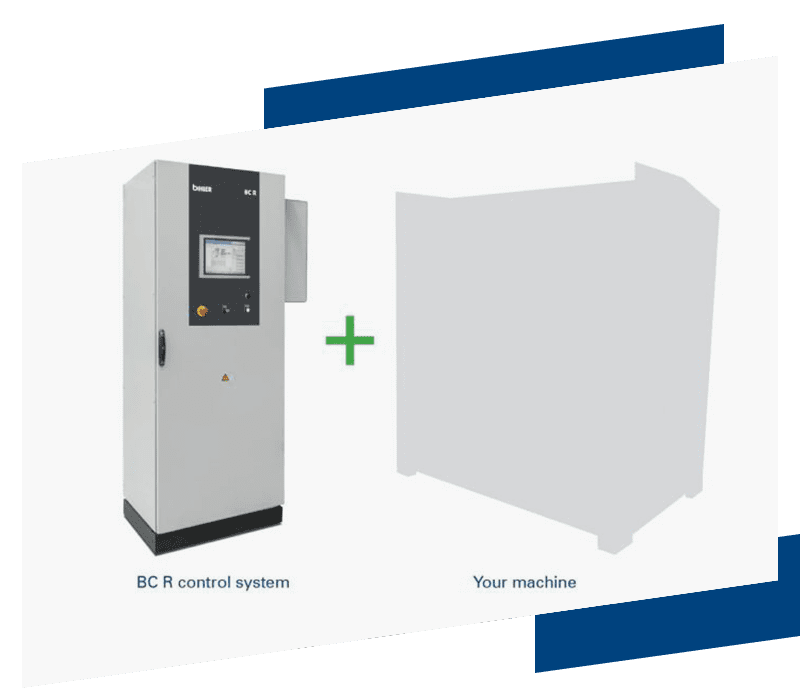

Control Retrofits

Upgrade your existing Bihler machines for new tasks. With the cost-effective BC R Retrofit package, this can now be done quickly and easily in three steps:

- We deliver the required machine components to your site.

- Service technicians will then retrofit your machine and install the BC R control system.

- Commissioning and approval.

The advantages of doing the retrofit: The machine is up to date, with full spare parts support, and as an option, network-capability for the digital age. Additional features, such as straightforward operation of the control system, monitoring functions, and manual operations, will make your machine even more productive.

Time required for the entire process: approximately one week!

- Cost-effective and fast realization

- Conversion time approximately 1 week

- Conversion takes place at your site

- Customized range of functions for continuous operation

- Latest safety standards for machines and personnel

- Higher machine availability and guaranteed spare parts support

To ensure you benefit from all advantages of the BC R control system, the machine must be equipped with various new features. These are included in the basic package. In addition, you can select further optional new features. Overview of the most important machine components:

Basic package

– Bihler Control Retrofit (BC R) process control system with 12“ touch display

– Control cabinet and basic electrical equipment with 4 door switches

– Conversion kit main drive with accessories and guard plates

– Rotary encoder with mounting flange

– Two-channel press safety valve for safe control of the pneumatic clutch

– Lubrication point sensor for monitoring bull gear lubrication

– Electronic handwheel with hand terminal HT 1

– Machine and tool control system

– Standard interface for reel (400 V, emergency stop)

Options

– Modernization of central lubrication and/or pneumatics

– Hydraulic conversion kit (Maximator) (if installed)

– Clutch NEW

– Roller chain NEW (if installed)

– Valve bank (with eight 5/3 way valves) to control cylinders

– End-of-material shutdown

– Second lubrication circuit

– Extension 400 V for second reel or other additional unit

– Extension 230 V (socket in control cabinet and at the machine)

– Remote service

– OPC UA

– Interface for conveyor and/or industrial extractor

– Additional door switch (e.g. for maintenance flap)

– Adapter loop line

– Individual cable installation / longer cables

– Conversion to LED lighting

– Conversion set to push-button door switch (only for Bihler soundproof cabins)

– Signal lamp (double RGB with 4 states)

Available for

– RM Series: RM-30 / RM-35 / RM-40

– GRM Series: GRM-50 / GRM-80 / GRM-100

– MACH Series: MACH-1 / MACH-1/7 / MACH-05

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin