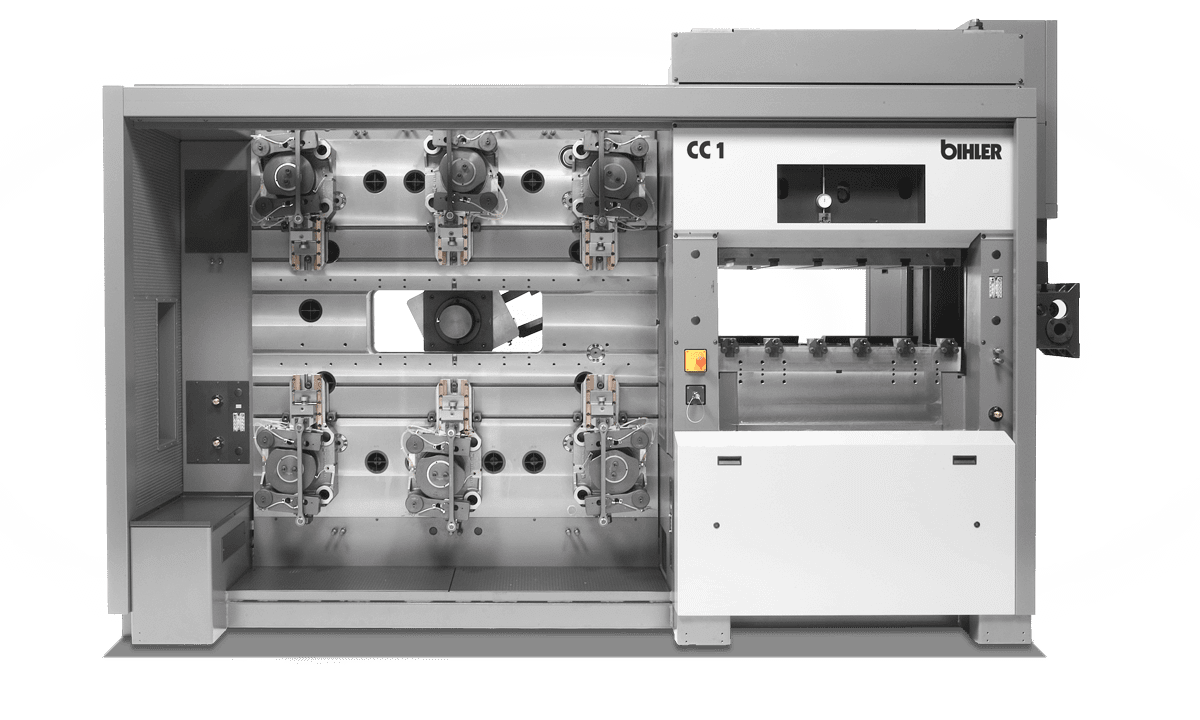

More Power and Free Space for New Perspectives

Redefine efficiency and precision in your production with the powerful COMBITEC multi-slide forming center. Engineered for exceptionally high punching forces and superior production speeds, the CC 1 is your ideal solution for manufacturing long, voluminous components and assemblies with unmatched efficiency.

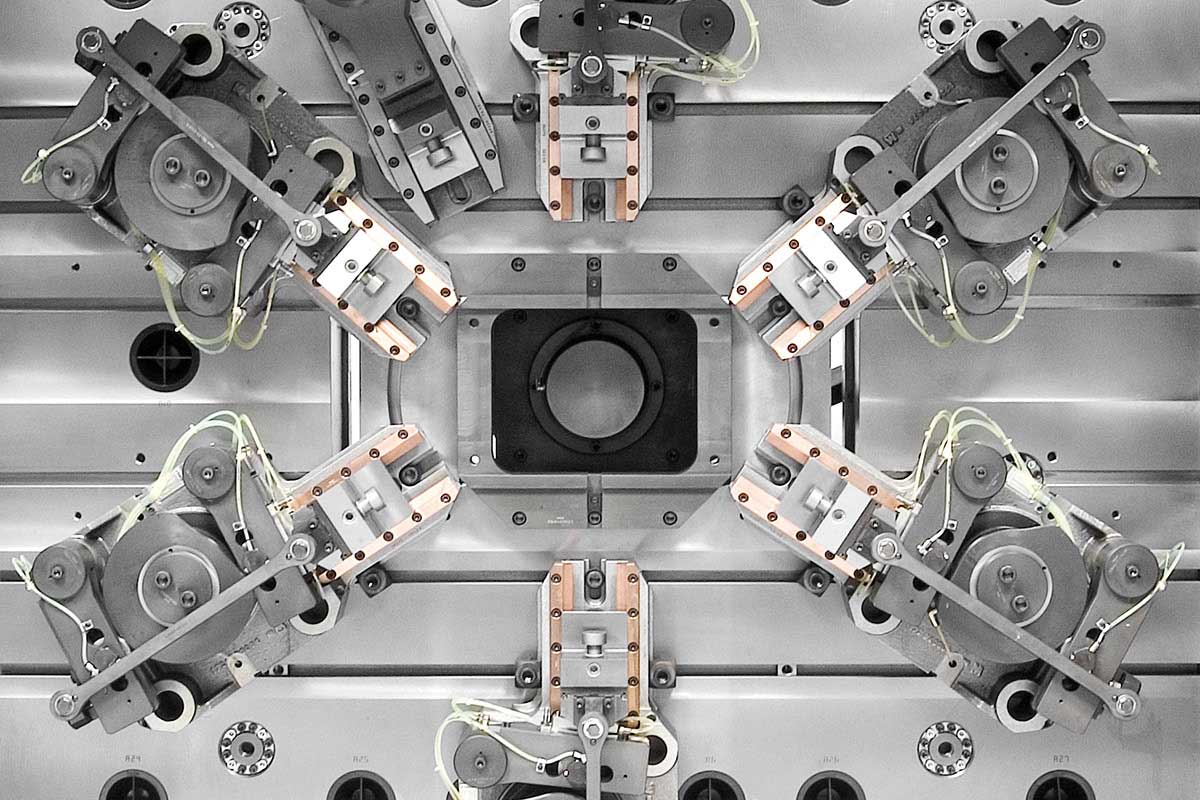

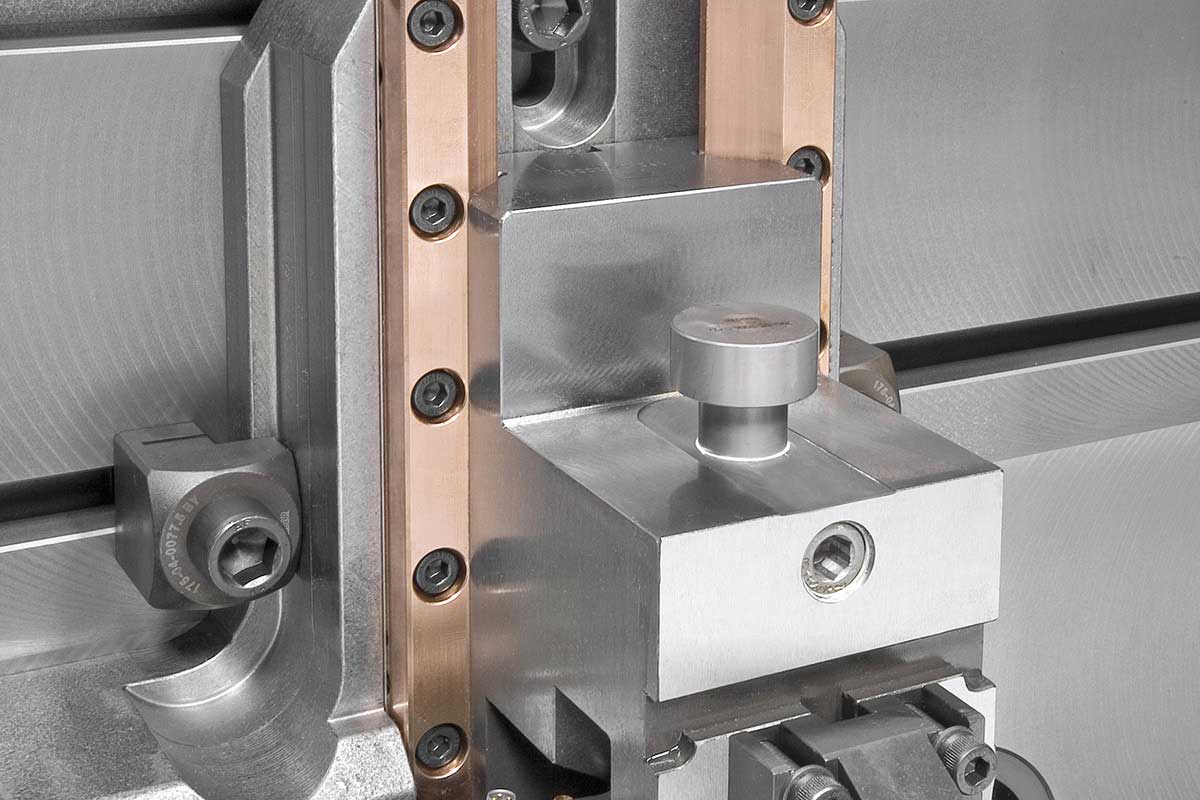

Designed for versatility, the 800 kN press is positioned adjacent to the worktable, providing generous space for punching, forming, and assembly operations, along with seamless integration of additional value-adding technologies. The quick-change tooling system minimizes setup times, while the intuitive VariControl system guarantees safe, user-friendly operation, empowering your team to produce with confidence and precision.

Machine Details

Powerful machining system for mass production of longer and larger-sized stamped and formed parts as well as sub-assemblies

- High production speeds of up to 200/min

- NC feed units available for long feed lengths

- Strong 800 kN eccentric press arranged beside the work plate

- Extended press space for larger cutting tools

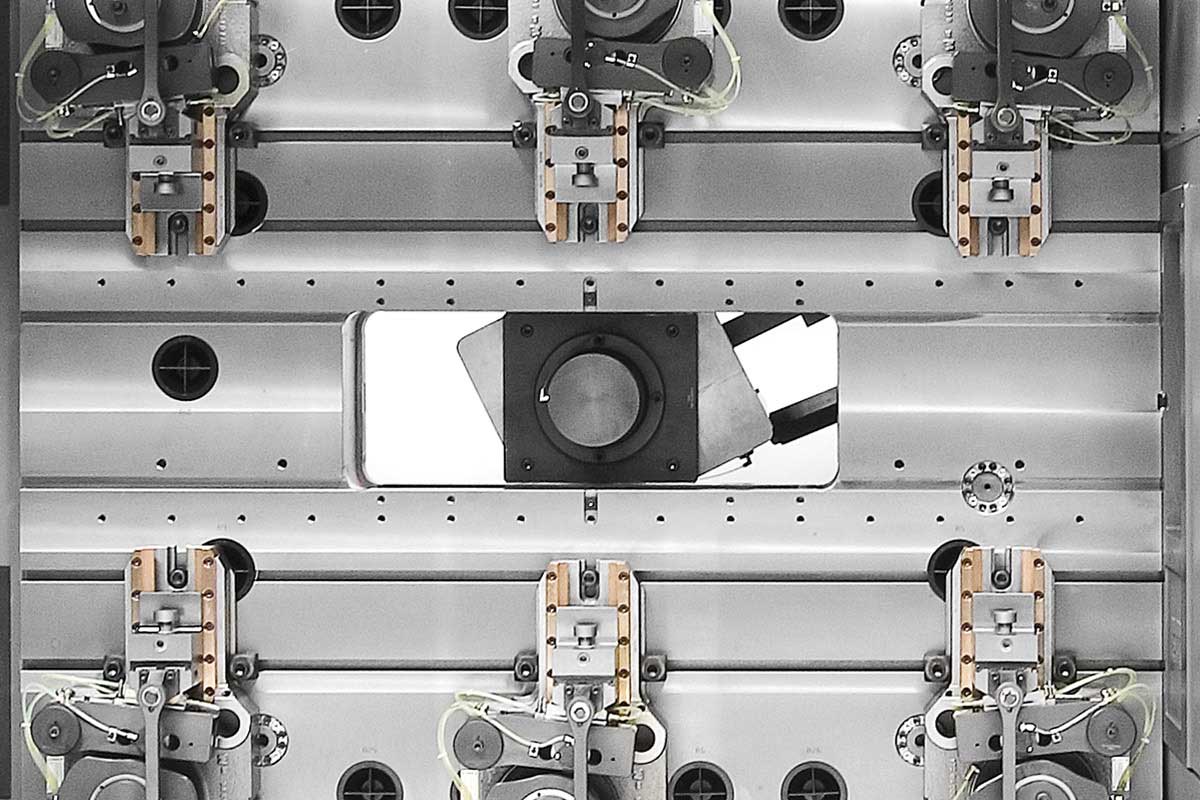

- Entire work plate available for additional processing steps (contact welding, tapping, inserting screws etc.)

- Large aperture in face plate to allow for several central mandrels

- Short changeover times with rapid tool clamping system

- Easy and secure operation with VariControl VC 1

| Stroke rate | Variable drive control from 5 to max. 200 1/min. |

| Max. nominal forming capacity 160 kN, max. stroke 140 mm | |

| NC gripper feed: max. 500 mm, NC roller feed: any feed length | |

| Material | Max. strip thickness: 10 mm, max. strip width 160 mm, max. wire Ø 10 mm |

| Width 4,200 mm x depth 1,900 mm x height 2,600 mm | |

| Weight | Approx. 12,000 kg (depending on units and tooling) |

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin