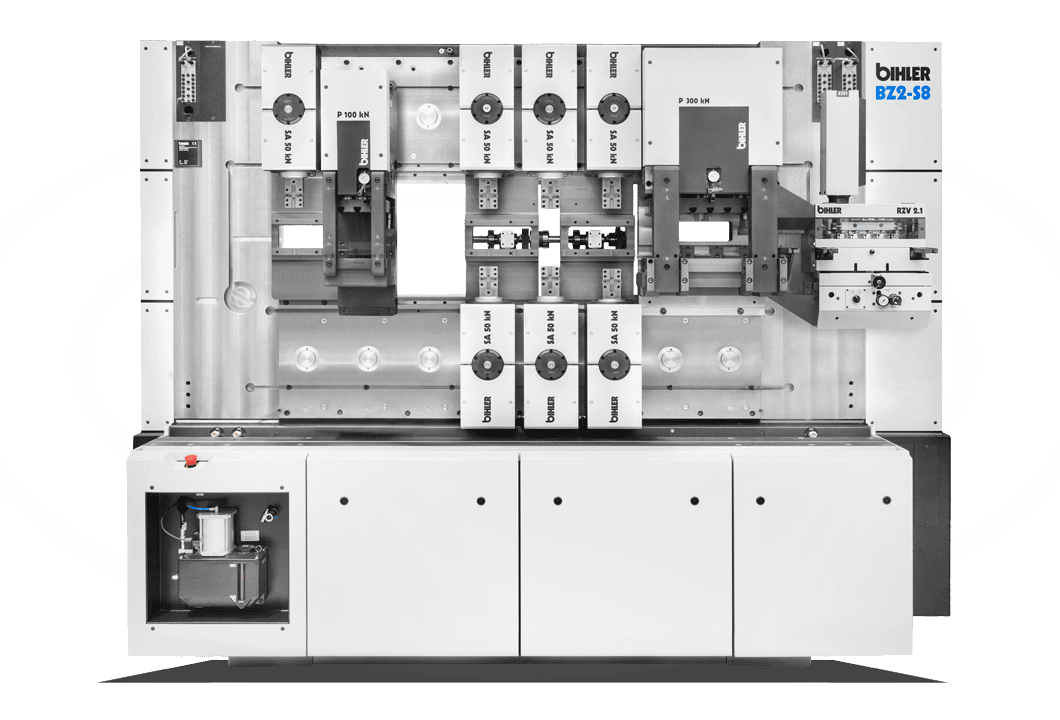

Revolutionizing Cam Disk Technology: Introducing the BZ2-S8

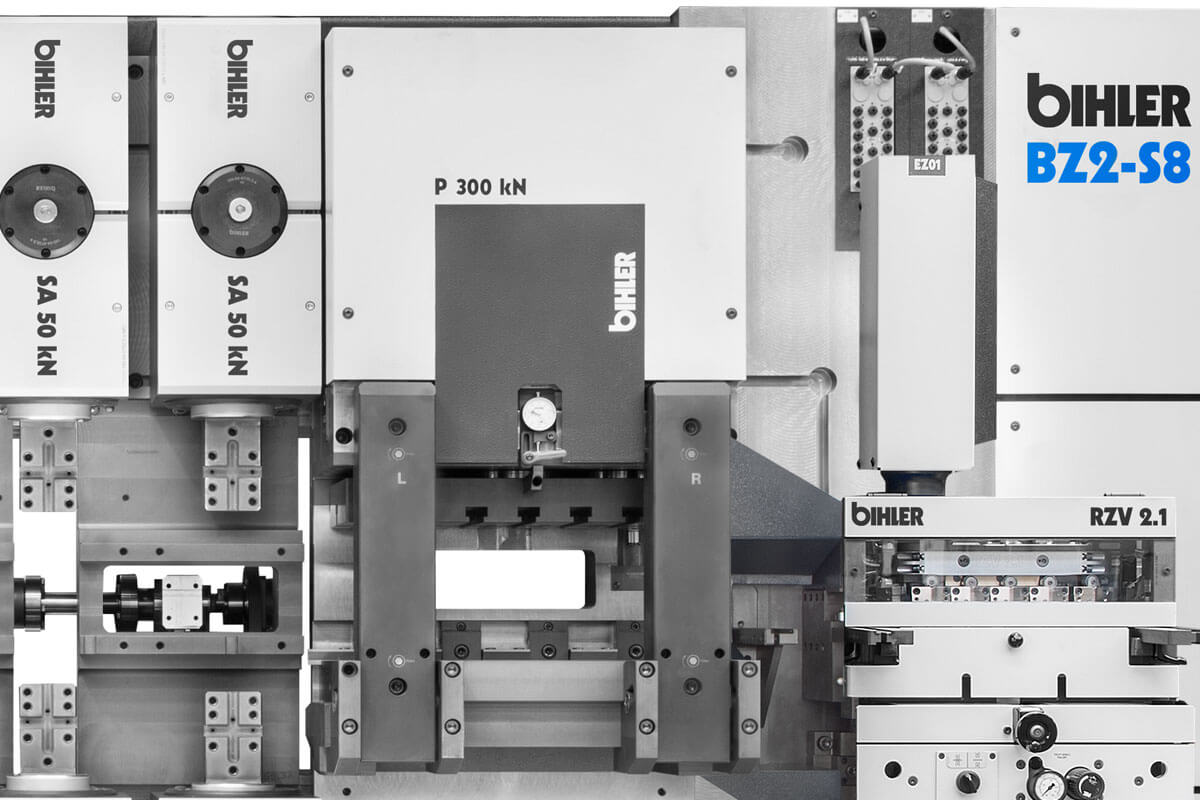

The BZ2-S8 represents the cutting edge of Otto Bihler Maschinenfabrik’s renowned processing centers, redefining what’s possible with cam disk technology. Packed with innovative features, the BZ2-S8 delivers unmatched performance, higher production speeds, and lower maintenance costs, setting a new benchmark for multi-slide efficiency and reliability.

With its roots in proven cam disk technology, the BZ2-S8 takes a giant leap forward in the stamping and bending industry. This next-generation system achieves incredible speeds of up to 700 strokes per minute, thanks to its completely redesigned drive system. By replacing the frequency-regulated three-phase motor with state-of-the-art servomotors, the BZ2-S8 offers greater precision, enhanced durability, and optimized performance.

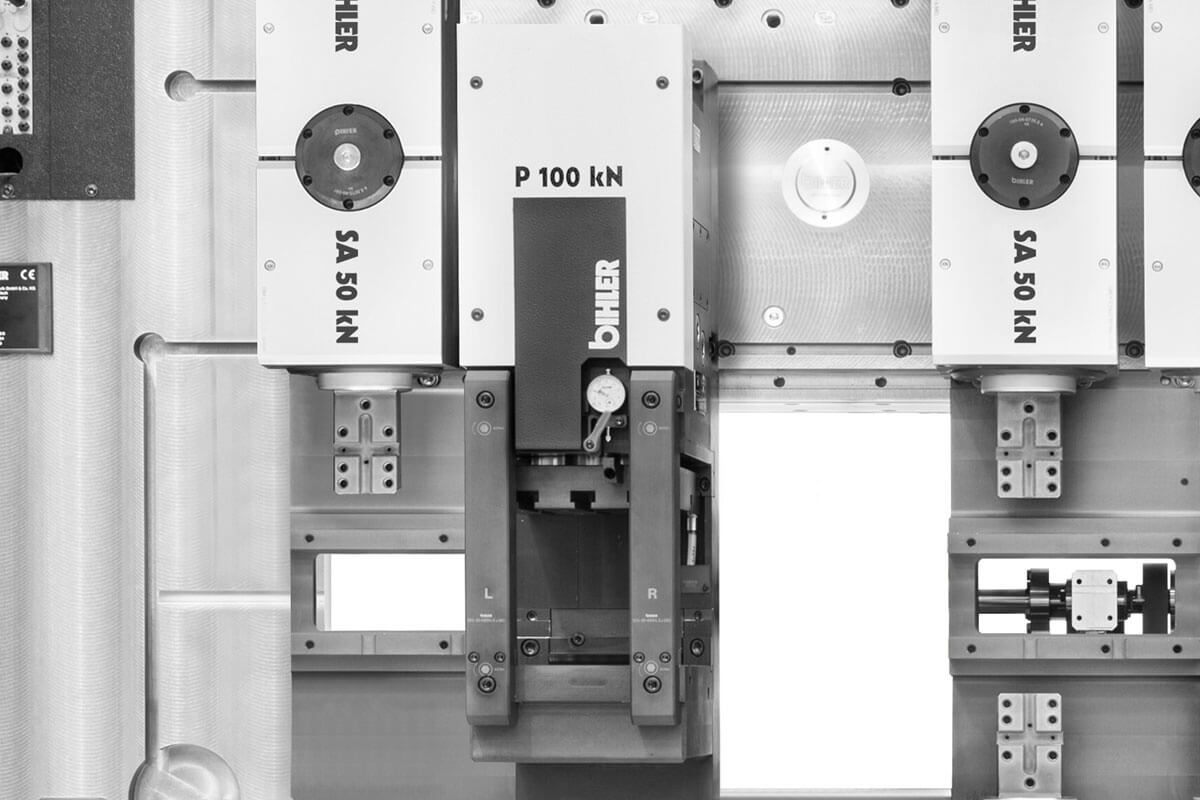

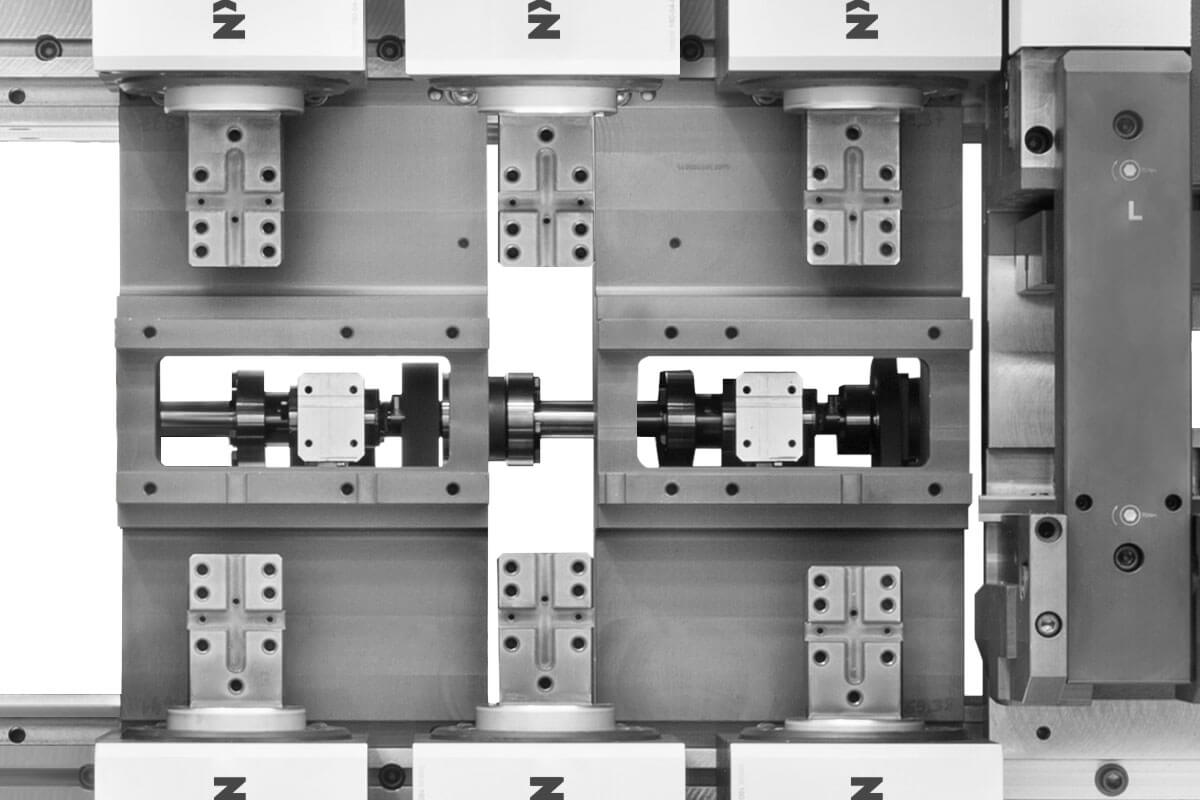

The system’s robustly upgraded slide units are built to withstand high-speed operations, ensuring consistent reliability even in demanding applications. As with all Bihler systems, the BZ2-S8 is seamlessly operated and controlled using the intuitive VC 1 controller, providing maximum control and ease of use.

The BZ2-S8 is more than a processing center—it’s a game-changer for manufacturers seeking the perfect blend of speed, innovation, and precision.

Machine Details

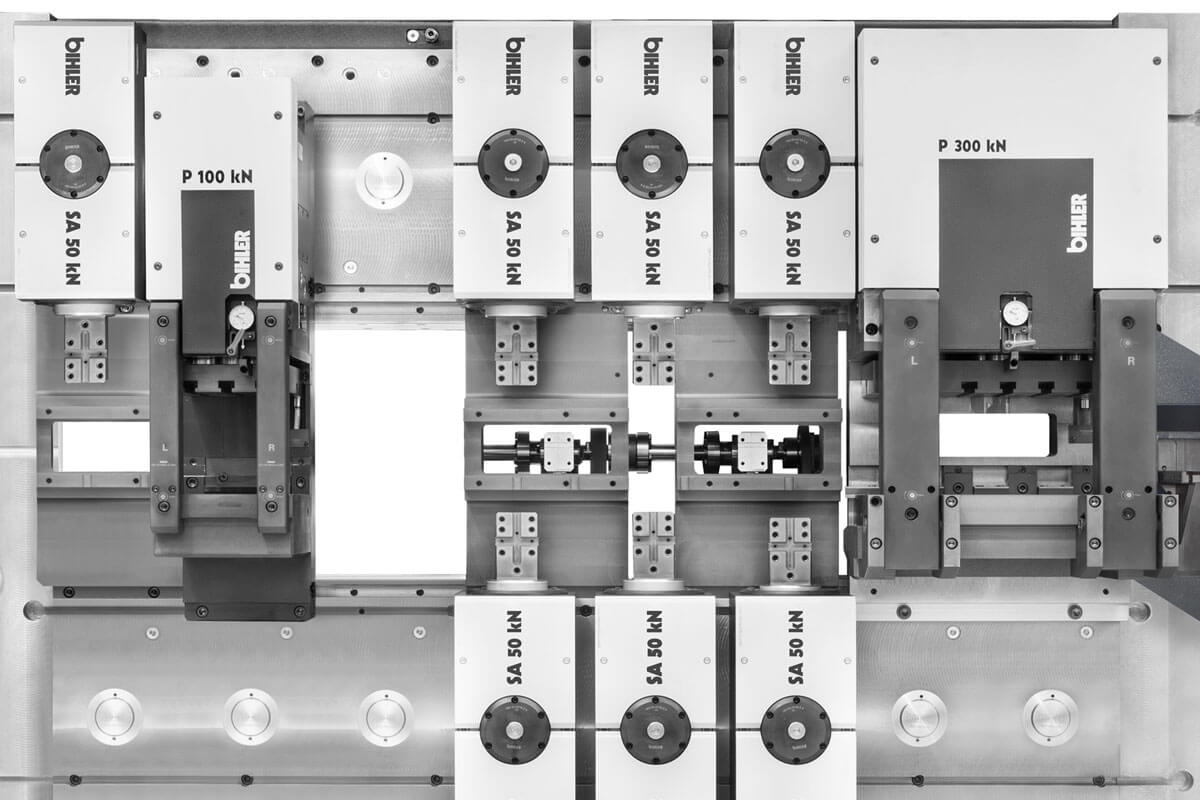

High-performance manufacturing system for mass production of stamped and formed parts and sub-assemblies

- High production speeds up to 700 spm

- New: All processing units driven by servo motors

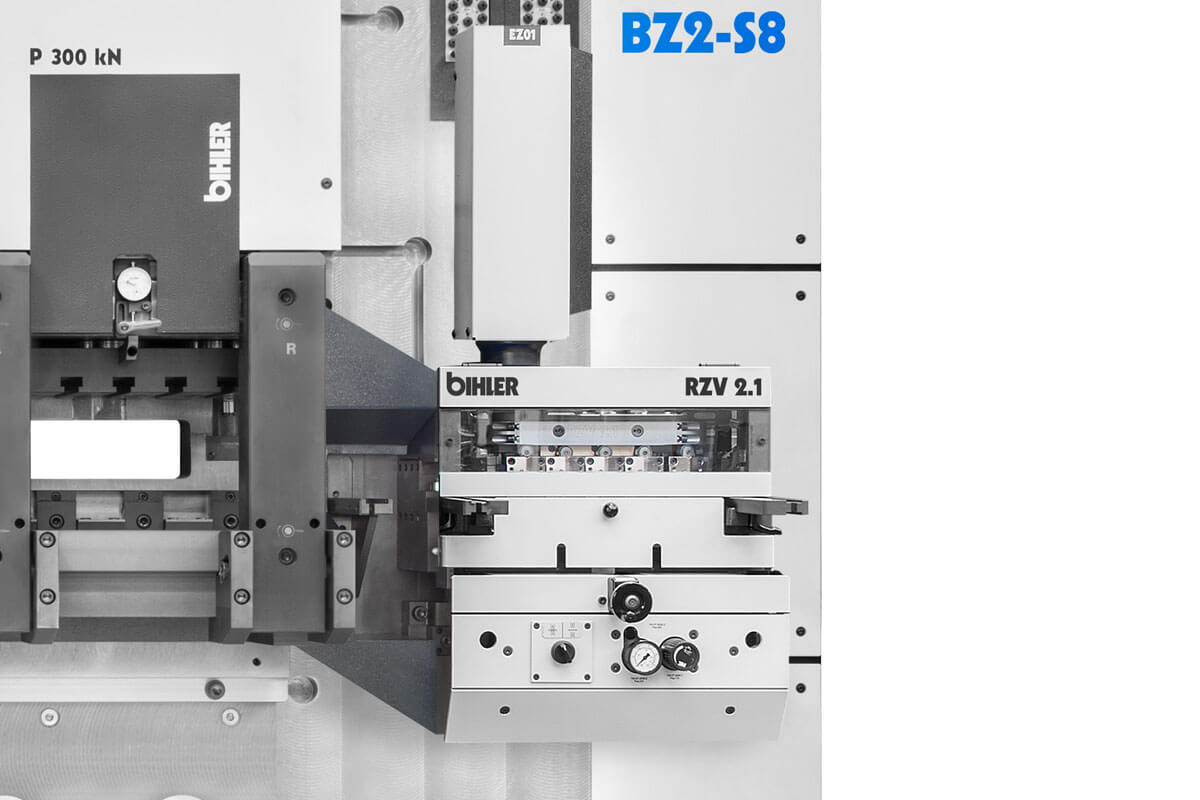

- New: Larger working space (plus 140 mm) for easy integration of processing modules

- New: Connection of presses and slide units to circulating lubrication system: drastically reduced oil consumption

- Convenient and secure operation with VariControl VC 1

Production of plug-connectors

| Stroke rate | Variable drive control up to 700 spm |

| Max. nominal forming capacity 50 kN, max. stroke 10 mm | |

| Mech. feed: max. 40 mm, servo feed: any feed length | |

| Material | Max. strip width 80 mm, max. wire Ø 4 mm |

| Width 2,950 mm x depth 1,400 mm x height 2,190 mm (without enclosure) | |

| Weight | Approx. 7,500 kg (with units and tooling, without enclosure) |

Optional Servo Modules

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin