E-Mobility Manufacturing Automation Solutions

Electric vehicles (EVs) and e-mobility aids are rapidly becoming the preferred choice for modern transportation. To meet this growing demand, you need state-of-the-art EV manufacturing equipment that delivers speed, precision, and scalability. Automated manufacturing solutions can transform your production processes, achieving levels of efficiency and speed that were previously unattainable.

At the Bihler Group of Companies, we have been industry leaders in innovation for decades. Our advanced systems are designed to help your company produce top-tier e-mobility solutions, including:

Bihler Advantages for EV Manufacturing Equipment

At Bihler, we put our best features in every machine, letting you experience the benefits of our innovation:

- High output rates: Depending on the nature of your products, some Bihler stamping and forming machines can reach output levels of over 300 parts per minute. Ensure your operations can keep up with the ever-growing nature of your industry by using the most efficient tools.

- Significant material savings: Bihler believes in efficiently using your materials while producing as little waste as possible. Our e-mobility manufacturing solutions can retain lost materials during linear and radial production to maximize material usage.

- Standardized, all-in-one production: Invest in new Bihler equipment or choose the modules you need to integrate our technology with your existing setup. Bihler machines are fitted with up to 70% standardized parts to work with other brands and fill the gaps in your current capabilities, from stamping and cutting to assembly and finishing.

- Short changeovers: Improved efficiency means reduced downtime. Replacing modules on Bihler systems to prepare for a new production phase only takes a few minutes, allowing you to get back to work quickly.

- Integrated monitoring stations: Ensure production stays up to speed and delivers products of consistently high quality with our integrated monitoring systems. This feature lets you observe production from start to finish and adjust immediately to respond to issues such as an updated specification or inaccurate measurement.

E-Mobility Manufacturing Consulting

If your electric vehicle company has an unmet need, such as an automated process for forming a part, our team can tailor standard Bihler e-mobility manufacturing solutions to address component-specific requirements. Whether this machine is your first piece of Bihler equipment or you’ve been our partner for years, an e-mobility consultation with our experts can take your manufacturing capabilities to the next level.

Our consultations help you maximize your company’s immediate return on investment. Our experts can provide more information on incorporating our easy-to-use equipment into your manufacturing process and adjusting the system’s programming to change its settings. Bihler strives to help our clients find success as safely and efficiently as possible, which we achieve through consultations, training and support services.

E-Mobility Components Manufactured on Bihler Equipment

Battery Busbars

Battery Busbars

Copper or aluminum busbars are critical elements in powerful battery systems and efficient electric power distribution.

Depending on the component’s length and geometry, busbars can be produced with high efficiency and flexibility using the GRM-NC servo stamping and bending machine, equipped with radial or linear bending tools. For additional value-added processes, the BIMERIC servo production and assembly system provides extensive processing versatility, enabling seamless integration of advanced manufacturing steps.

Bihler’s equipment allows for flexible, high-volume production of busbars of varying configurations. Manufacturers can realize significant material savings – up to 50% in radial production and up to 33% in linear production with lengths of over 2000mm. Tooling is cost efficient and standardized and requires very short tool changeovers ranging from 30 minutes to 1.5 hours, and with our integrated monitoring stations, you can realize consistent production reliability and quality.

Cell Contact System for Battery

Cell Contact System for Battery

The battery powering an electric vehicle consists of a large number of individual cells that are connected to one another by means of a cell contact system. It is important to use a high-performance cell interconnect which minimizes power loss, ensures the best possible equalization between the cells and is also suitable for a fast, uncomplicated assembly.

In practice, the illustrated cell connectors are manufactured and mounted in the carrier frame on a Bihler servo production and assembly system.

Our equipment expertly handles production from start to finish. It not only fabricates the high-precision interconnects of the contact system, but also assembles them with other parts within a carrier frame. Complete assembly throughput is capable of producing four complete cell holders per minute. This equipment combines speed, precision, and comprehensive functionality, meeting the demands of professional e-mobility manufacturing environments.

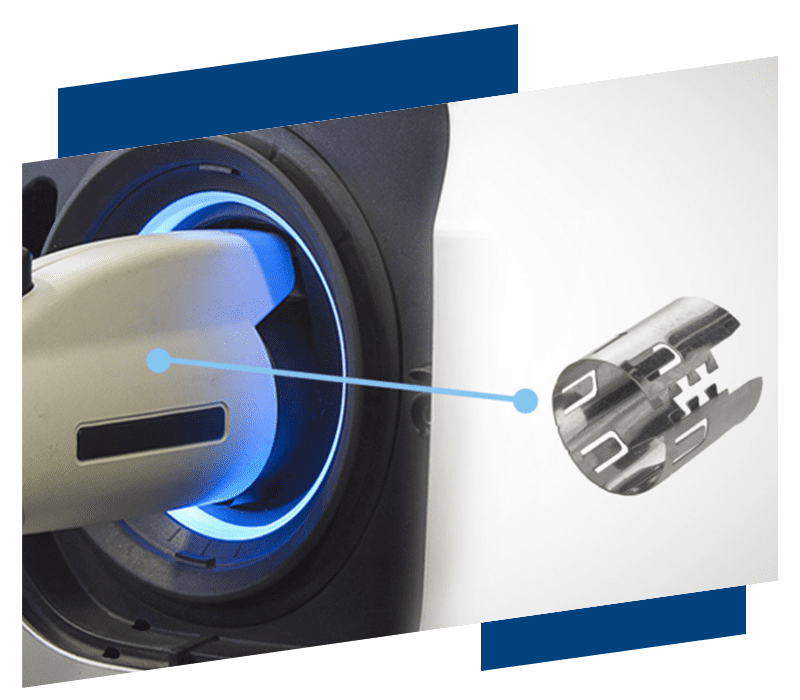

Charging Plug Shielding Sleeves

Charging Plug Shielding Sleeves

Shielding sleeves protect and provide safety for both conductive and circumferential components from electrical or magnetic disturbances. Fabricated with our fine-detail servo stamping and forming machine and enhanced with our state-of-the-art LEANTOOL linear system, these sleeves exemplify craftsmanship and innovation.

Our equipment redefines precision manufacturing for delicate parts. It’s capable of producing these shield sleeves at a rate of 170 parts per minute and allows for 100% reproducible variant changes in less than 30 minutes thanks to cost-effective and highly standardized tools.

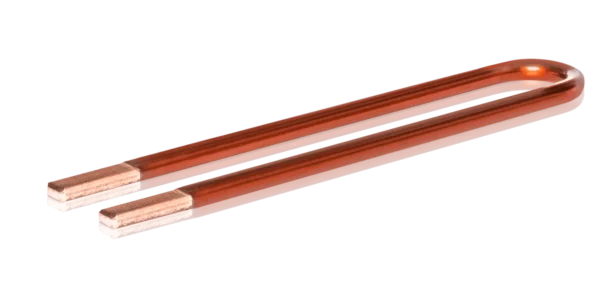

Hairpin Windings for Electric Motors

Hairpin Windings for Electric Motors

At the core of every electric motor lies the conductor coil, which generates magnetic fields when electricity flows through it. These magnetic forces are then transformed into kinetic energy, powering the motor. Depending on the design, the conductor coil is made up of multiple windings of an electrical conductor, typically in the form of wire or stranded wire.

The key component of any primary winding is the U-shaped winding element, also known as a hairpin. The example shown here is a winding element used in the electric motor of e-bikes. This precise component is manufactured on a hybrid stamping and bending machine, the RM 40K with NC units, ensuring exceptional precision and efficiency.

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin