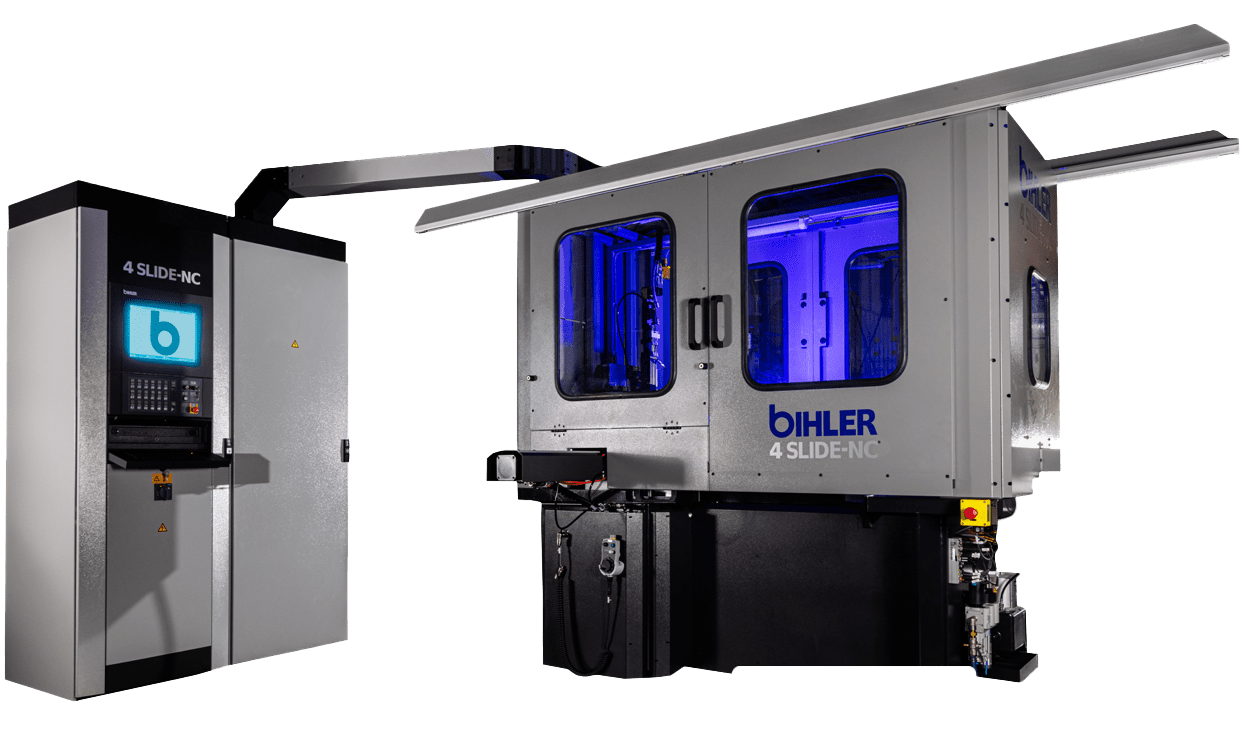

Bihler 4Slide-NC®

The Future of 4 Slide Machine Technology is Here

The Future of 4 Slide Machine Technology is Here

Highlights 4 Slide-NC

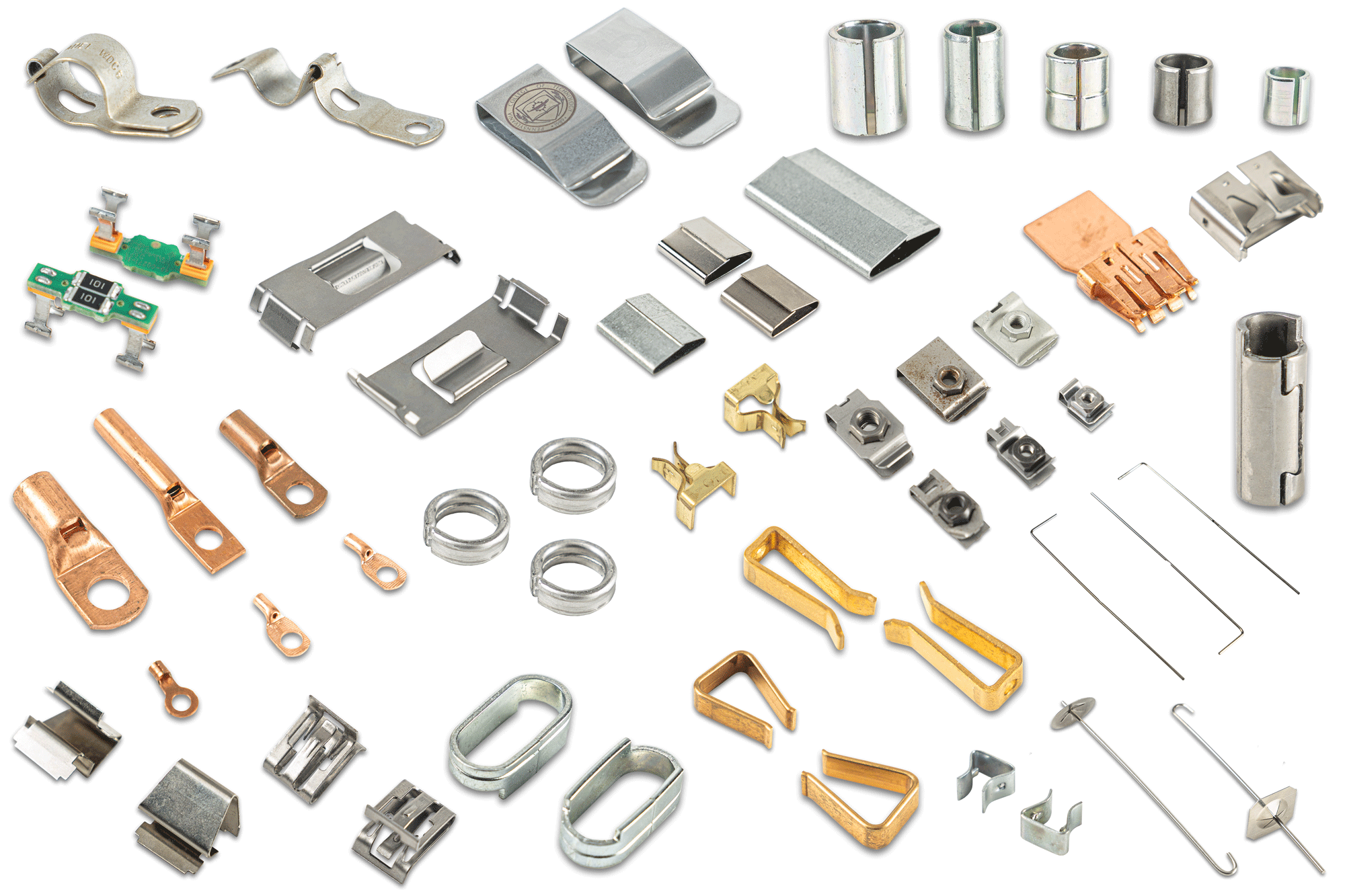

Take your old 4 Slide tooling and future proof it by putting it onto our 4 Slide-NC. Optimize your production value with increased production speeds and decreased change over times, some as little as 1 hour! Our 4 Slide-NC is the future of 4 Slide Manufacturing thanks to our Servo NC and VC-1 Technology.

- High speed production of up to 250 parts per minute.

- Utilize existing 4 Slide tooling on our machine, saving costs.

- NC, programmable cams for ease of process optimization.

- Integrated monitoring capabilities.

- Multiple press options up to 28 Tons.

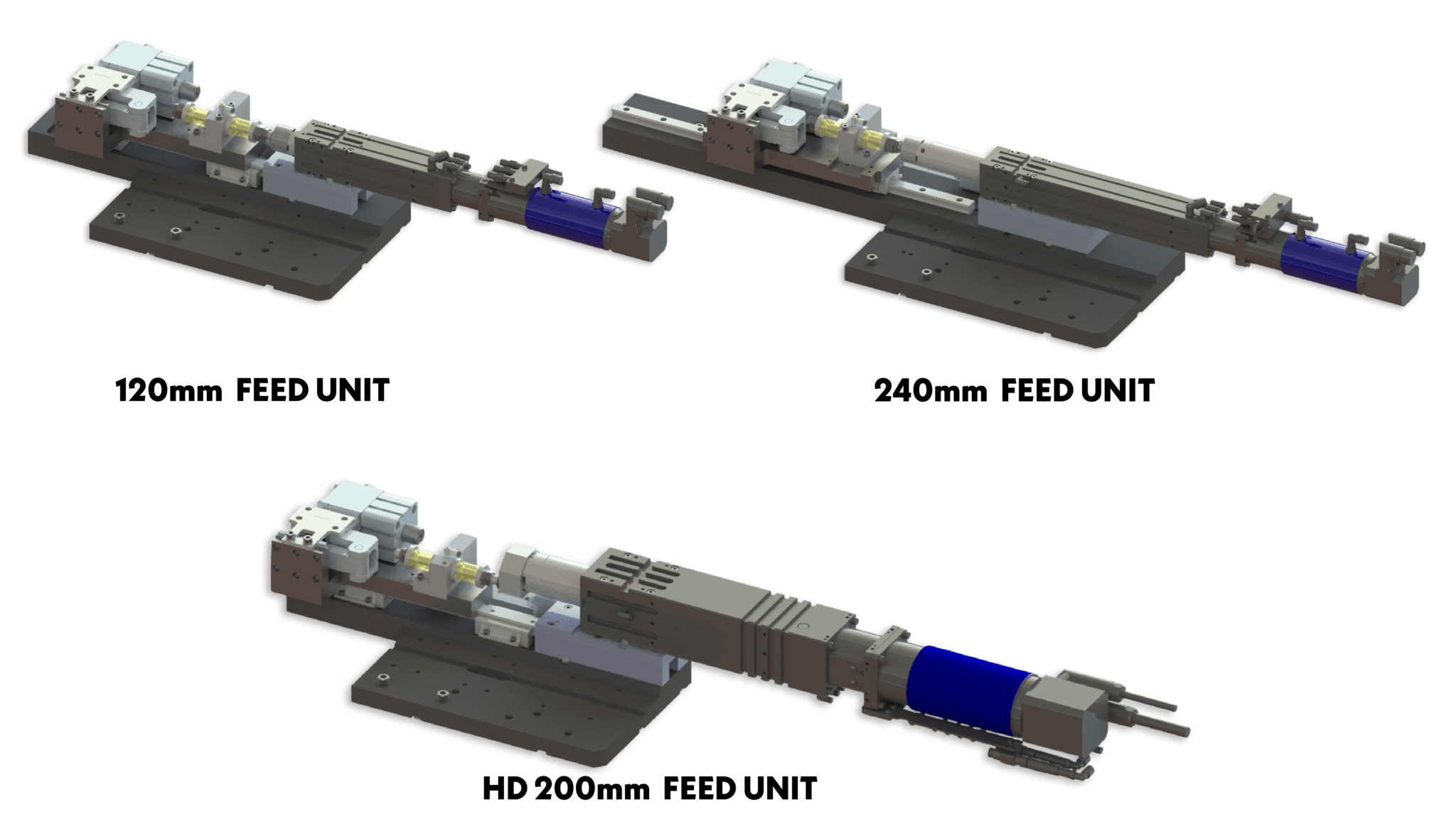

- 120mm, 240mm and Variable feed lengths thanks to the RZV Feed Unit.

- 100% reproducibility of parts with VC-1 Controller.

- 1 Hour tool set up time, no more mechanical cam set ups.

- Remote login ability for troubleshooting assistance.

Technical Data

- Stroke rate: Variable from 5/min up to 260/min with press and 300/min with out the press

- Press: Standard 7 or 21 ton press, optional 14 and 28 ton.

- Slide Units: Nominal forming capacity is 4 tons per slide

- Feed Length: Standard is 120mm, optional 240mm and endless (RZV Feed unit)

- Material: Max. strip thickness 1.8mm, max width 55mm Max wire ø 4mm (material dependent)

- Machine Dimensions: 152”x 85” not including decoiler, control cabinets and chiller

- Machine Weight: 5,000lbs, Control Cabinets 2,000lbs

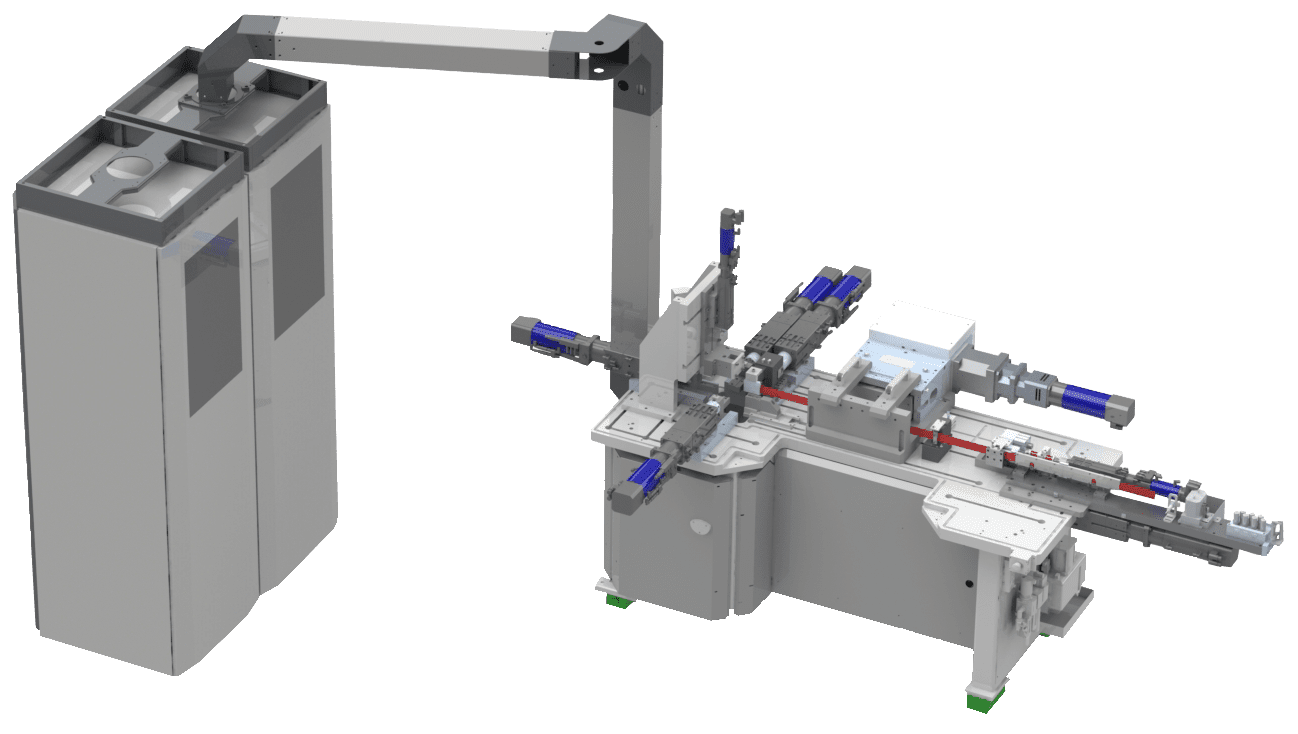

Machine Platform

Custom machine base manufactured to the highest standards of tolerancing and flatness to ensure the ultimate precision metal forming ability. Specially designed to incorporate all your air, oil, cooling and electrical needs, to create a clean and accessible working platform. Modular design allows for additional servo motions as well as value added processing units, upgrade your forming capabilities to allow for: Welding, Tapping, Screw Insertion and other features. Standard 4 Slide NC systems include:

- 1x 120mm feed length (240mm or RZV optional)

- Standard Presses: 7 or 21 Ton Press (14 and 28 Ton upgrades optional)

- Forming Slides: 4x 120mm Stroke, ~2 Tons of Forming Force

- Cutoff Slide: 1x Xmm Stroke, ~2 Tons of Cutting Force

- Mandrel: 1x 120mm Stroke, ~ ¼ Ton of Force (Optional upgrades)

- VC-1 Controller

- Chiller (not standard)

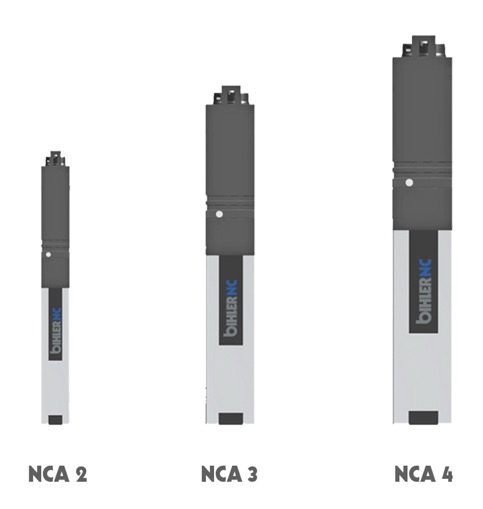

BIHLER NCA SERVO

Compact and powerful servo units for quick and exact execution of tool movements. Coupled with smart tooling design, reduce your set up time, up your efficiencies and utilize your existing Forming Tools to complete your jobs.

- Process speeds of up to 400 strokes per min. (application dependent)

- Freely programmable stroke movements and movement profiles

- Maximum power can be selected freely across entire operating range, no fixed BDC.

- No mechanical components to change during setup

- Various sizes and designs depending on the application

Technical Data

- NCA 2- Forming Force: Max. 1.5kN. 120mm stroke

- NCA 3- Forming Force: Max. 3.5kN. 120mm stroke

- NCA 4- Forming Force: Max 19kN. 120mm stroke

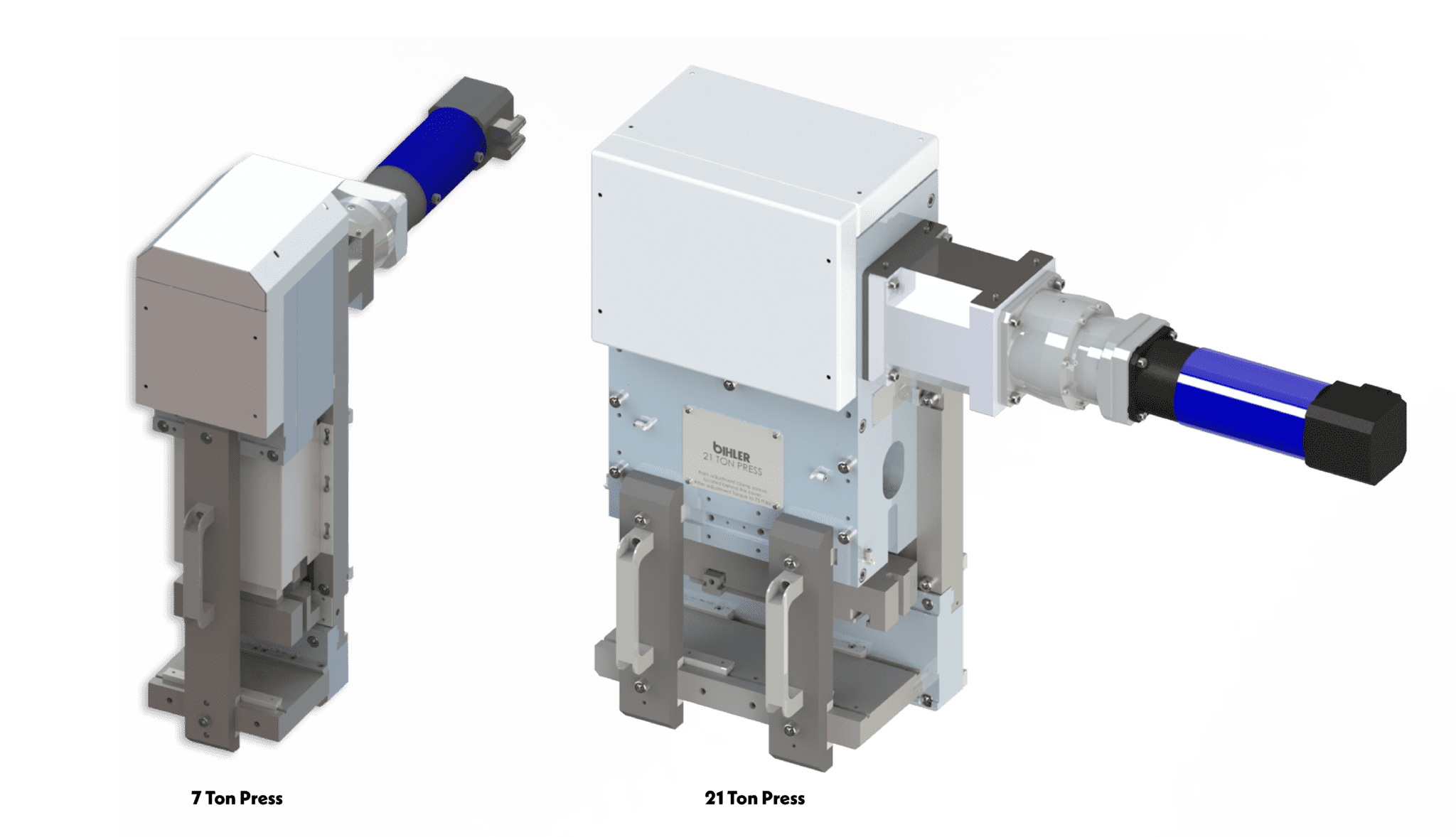

4 SLIDE SERVO PRESS

With 4 size options and speeds up to 250 strokes a minute, Bihler 4Slide NC presses can also be equipped with under press NC motions for added processing advantages. Depending on size and layout, multiple presses can be incorporated to the machine bases for all your stamping needs.

Technical Data

- 7 Ton Press

- 14 Ton Press

- 21 Ton Press

- 28 Ton Press

- Integrated press force monitoring and overload protection, bearing temperature monitoring and connection to the oil circulation lubrication system.

Machine Control

The VariControl VC 1 (Version 3.0) provides a full range of machine and process control functions. It controls, regulates and monitors all machine and process functions. Freely programmable digital and analog I/0 bus modules have been integrated on the machine side, which serve to operate, monitor, and safeguard the tooling and process technology.

Operation and Visualization

Designed to be simple, the control interface is divided in a structured arrangement and can be easily and conveniently operated. Customized menu interfaces for the machine, process and tool areas, clearly displayed machine conditions, functional areas (e.g. process module, infeed, or tool clamping), and production overview have all been integrated and provide for easier and more structured operation.

The redesigned control panel is now combined with a 24-inch multi-touch display. In 16:9 format, this enables larger views, the display of additional information and operation with several fingers for zooming in.

Questions on the 4 Slide NC?

MORE MACHINE INFO

- The 4Slide-NC has 4 movements plus a Press Tool (Standard)

- You have the ability to add a secondary central mandrel motion

- A secondary press can be added to the 4 Slide, inline

- Cutoff Slide: 4,000 lbs or 2 Tons, 120mm stroke

- Mandrel: 4,000 lbs or 2 Tons, 120mm stroke

- VC-1 Controller

- Chiller

Frequently Asked Questions

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin