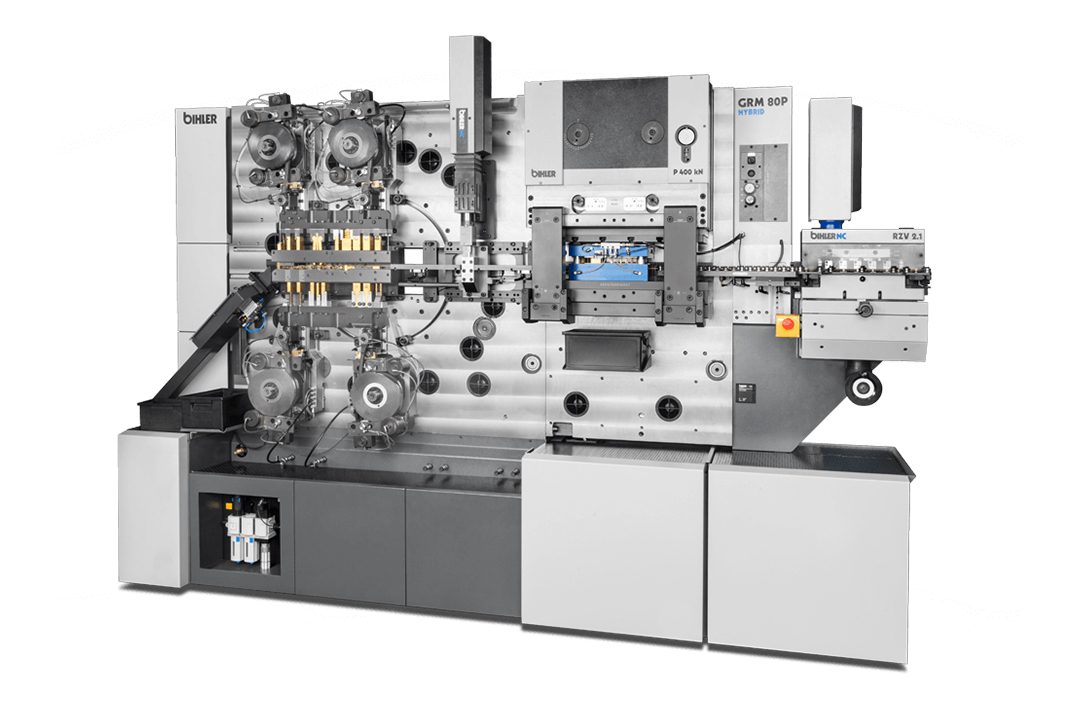

Mechanics Meets Servo Technology

Experience the perfect synergy of mechanics and servo technology with the GRM 80P Hybrid stamping, forming, multi-slide machine. Delivering unmatched performance and flexibility, this advanced system enables you to produce precision stamped and formed parts and assemblies with exceptional productivity and cost-efficiency. Take your manufacturing to the next level with the cutting-edge technology of the GRM 80P Hybrid.

Machine Details

Powerful machining system for flexible mass production of larger stamped and formed parts as well as sub-assemblies

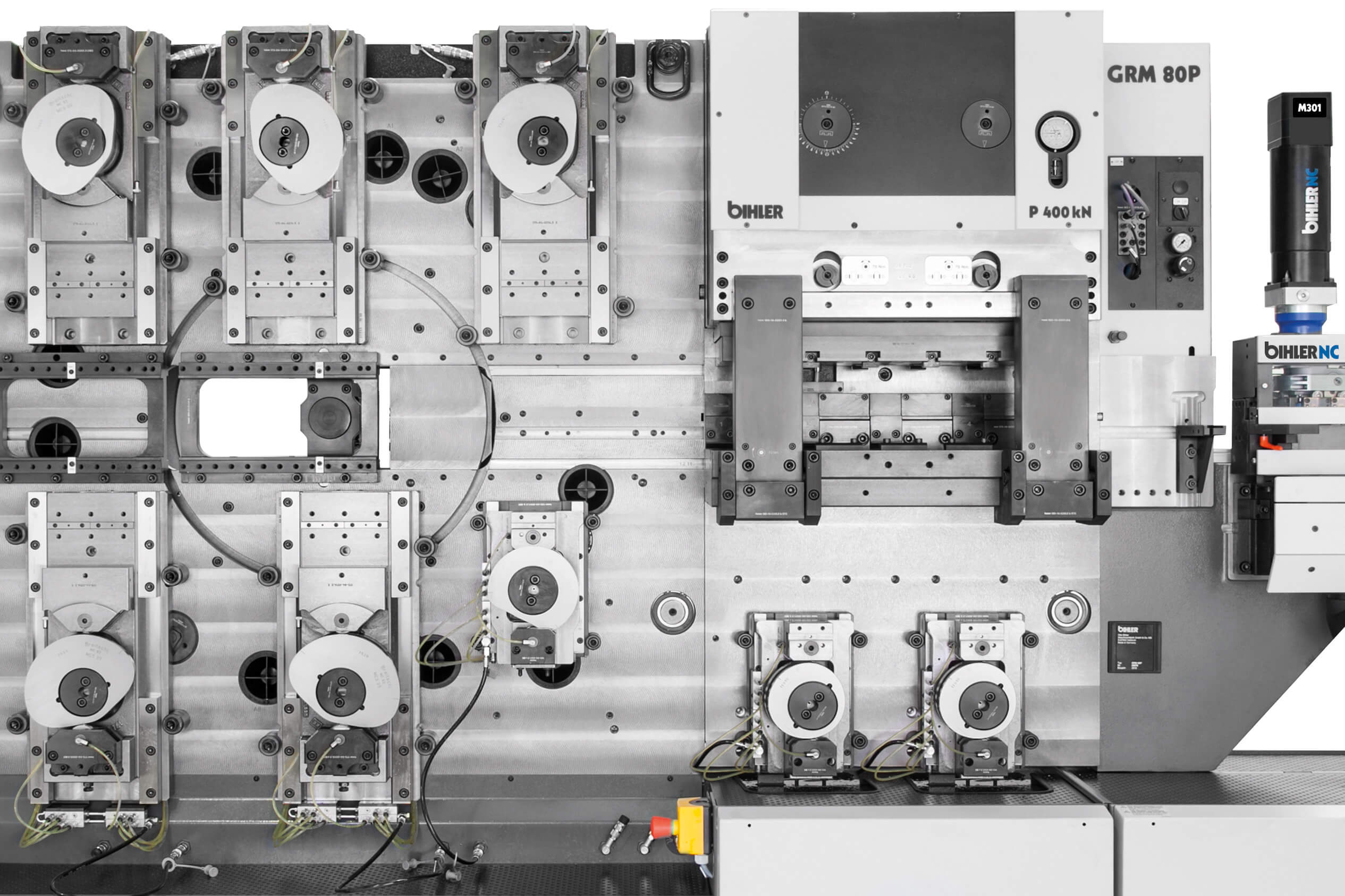

- Easy integration of servo axes for easier tooling solutions (high flexibility in case of variant diversity)

- Maximum processing room due to spatial separation of stamping and forming operations

- More than 2,100 mm (82”) machining path with linear tools

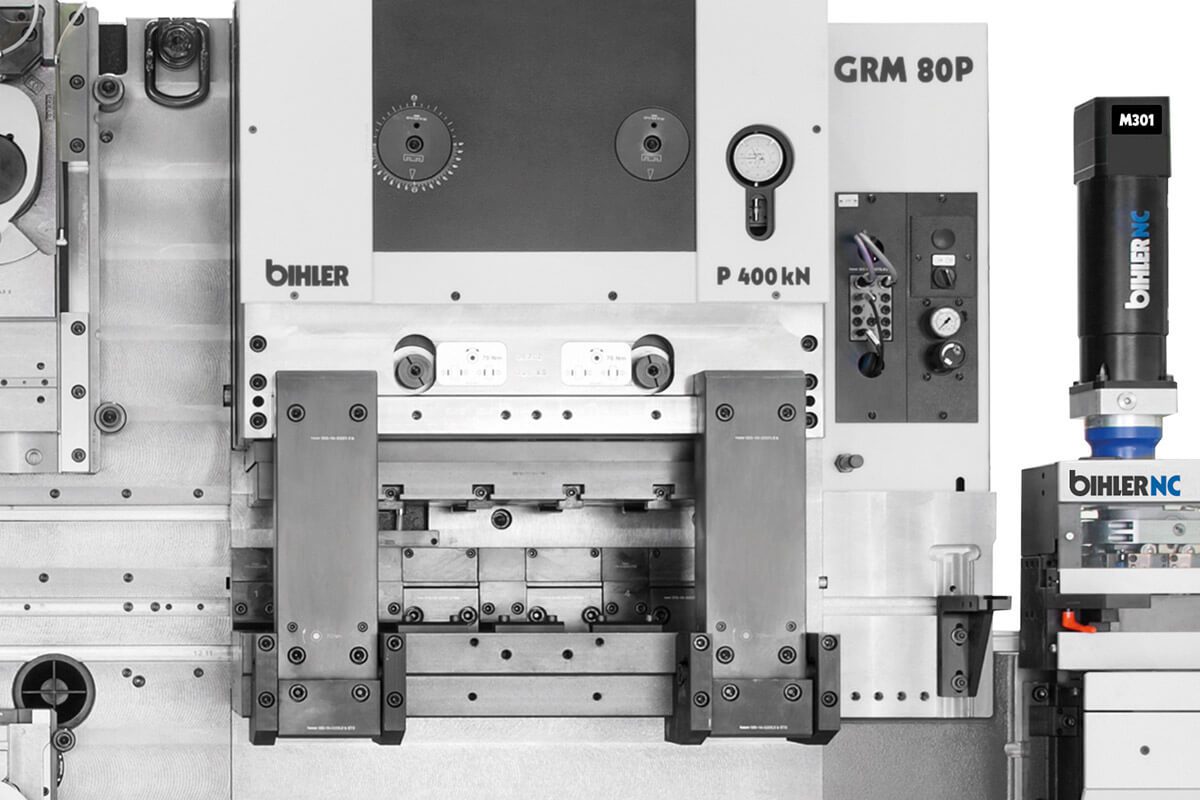

- Rigid 400 kN press for high-performance carbide tools

- Large center aperture for flexible integration of NC central mandrels (complete set-up from machine front side)

- Easy and secure operation with VariControl system

| Stroke rate | Variable drive control from 5 to max. 250 1/min. |

| Max. nominal forming capacity 90 kN, max. stroke 95 mm | |

| NC feed: any feed length, mech. feed: max. 500 mm, with feed cycle reduction | |

| Material | Max. strip thickness: 6 mm, max. strip width 80 mm, max. wire Ø 6 mm (depending on material and process) |

| Width 3,930 mm x depth 1,595 mm x height 2,220 mm | |

| Weight | Approx. 4,500 kg (without tooling) |

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin