Coil Assembly for Electronic Stability Program (ESP)

Coil Assembly for Electronic Stability Program (ESP)

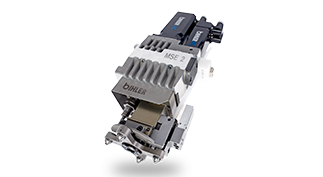

The Electronic Stability Program (ESP) detects an impending instability of a vehicle. It intervenes instantly, ensuring that the vehicle remains easier to control for the driver and does not start skidding. Similar to an ABS system, the ESP system also operates using valves which must be controlled precisely and reliably.

This is ensured by the coil assembly that can be efficiently manufactured on a BIMERIC servo production and assembly system – from feeding all the components to the finished products on pallets. The cycle time is 1.5 seconds per component. The retooling from one version to another is completed in mere minutes.

Coil Assembly for Electronic Stability Program (ESP)

Coil Assembly for Electronic Stability Program (ESP) Head Restraint Tubes

Head Restraint Tubes Head Restraint Adjustment Mechanisms

Head Restraint Adjustment Mechanisms Battery Terminal Clamps

Battery Terminal Clamps Cylindrical Plain Bearing Bushes

Cylindrical Plain Bearing Bushes