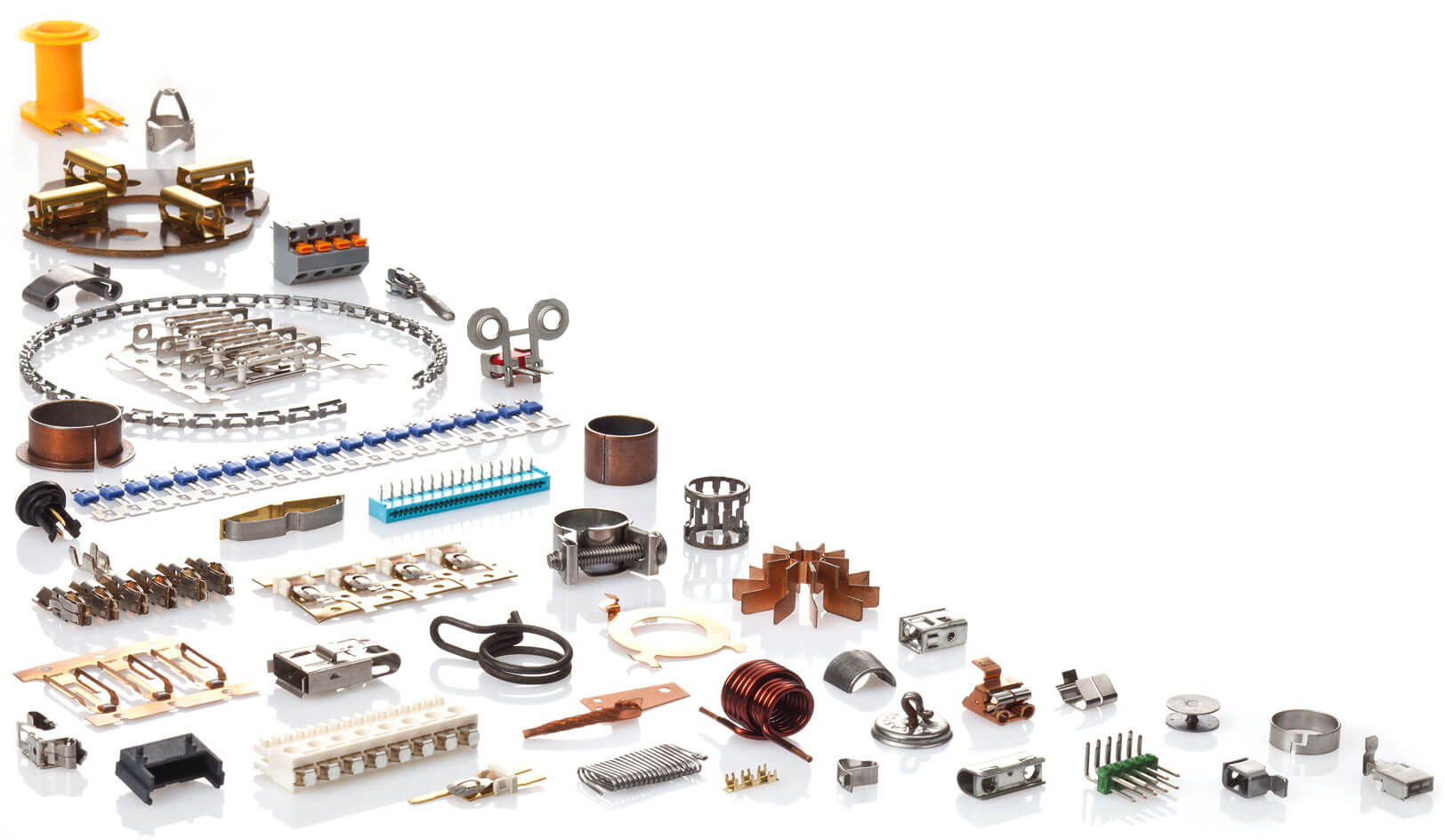

Powerful machine system for enlarged parts range (stamped and formed parts made from high-tensile metal)

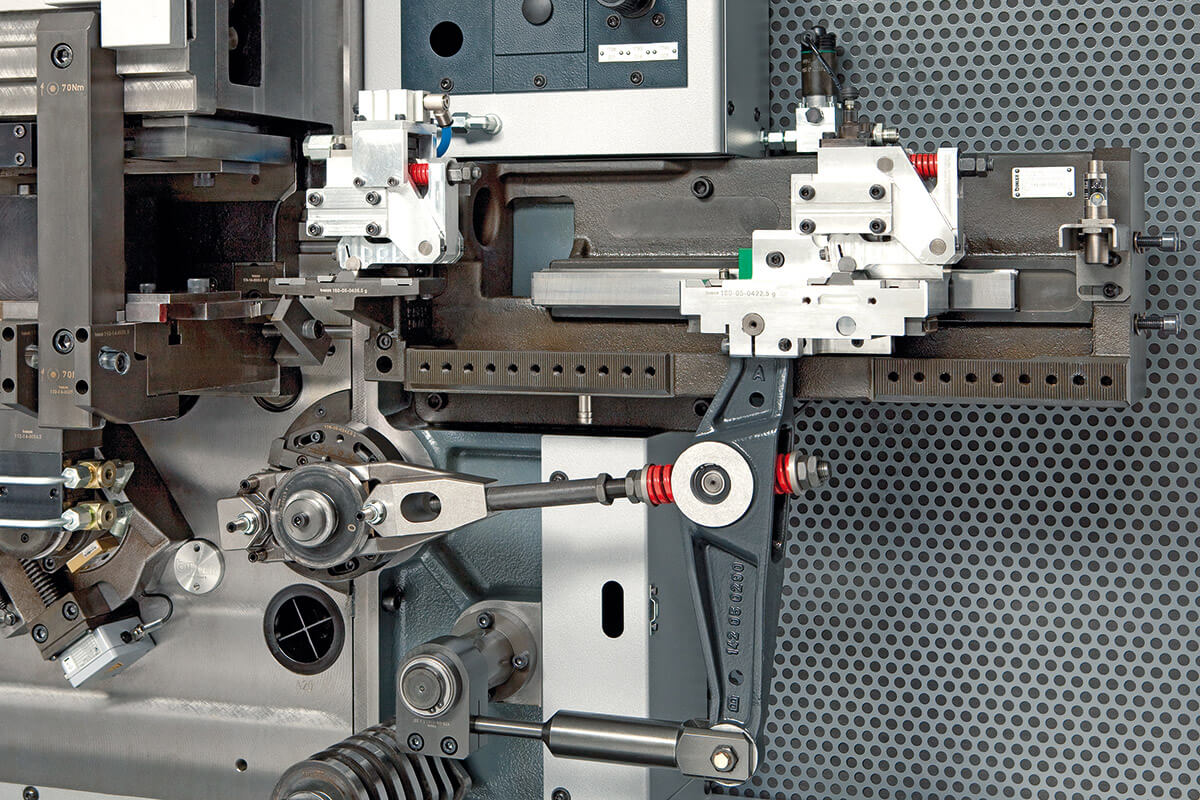

- High production performance up to 350 1/min.

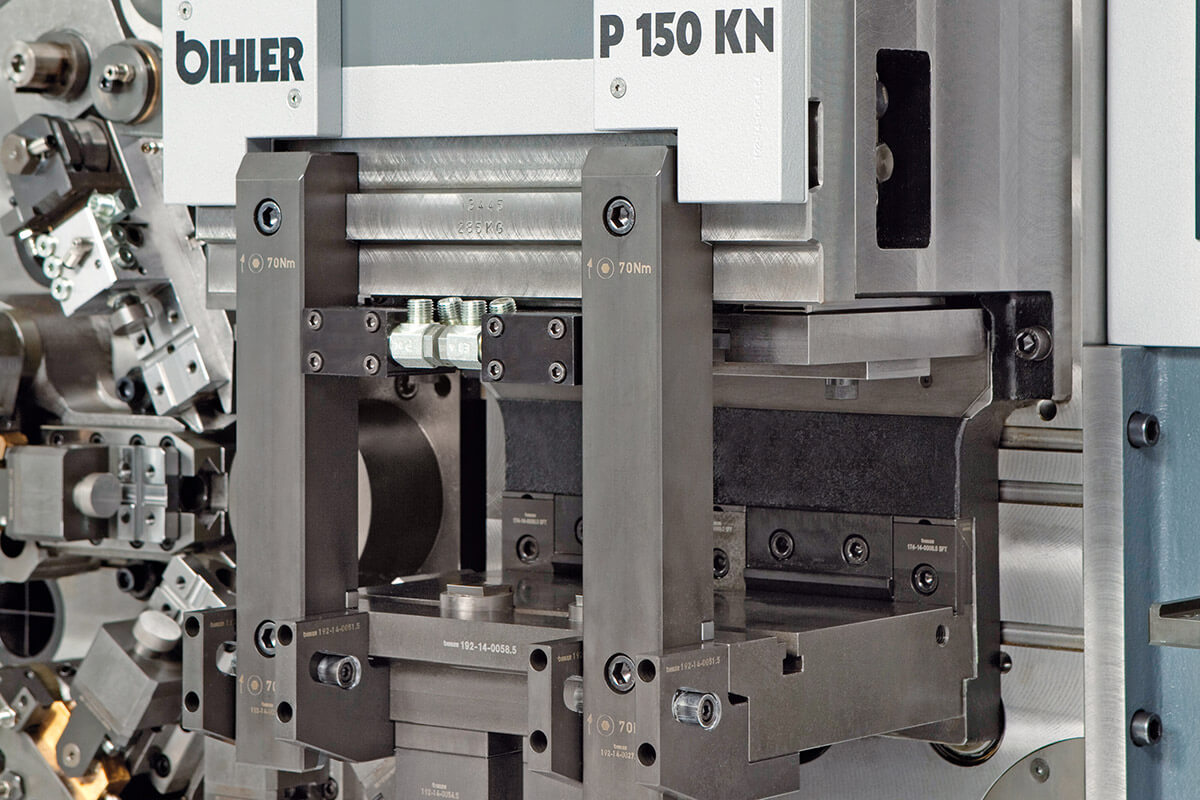

- Strong 150 kN two-point eccentric press unit with large mounting area

- High press rigidity allows the use of high performance carbide tools

- Guaranteed process reliability through press force monitoring

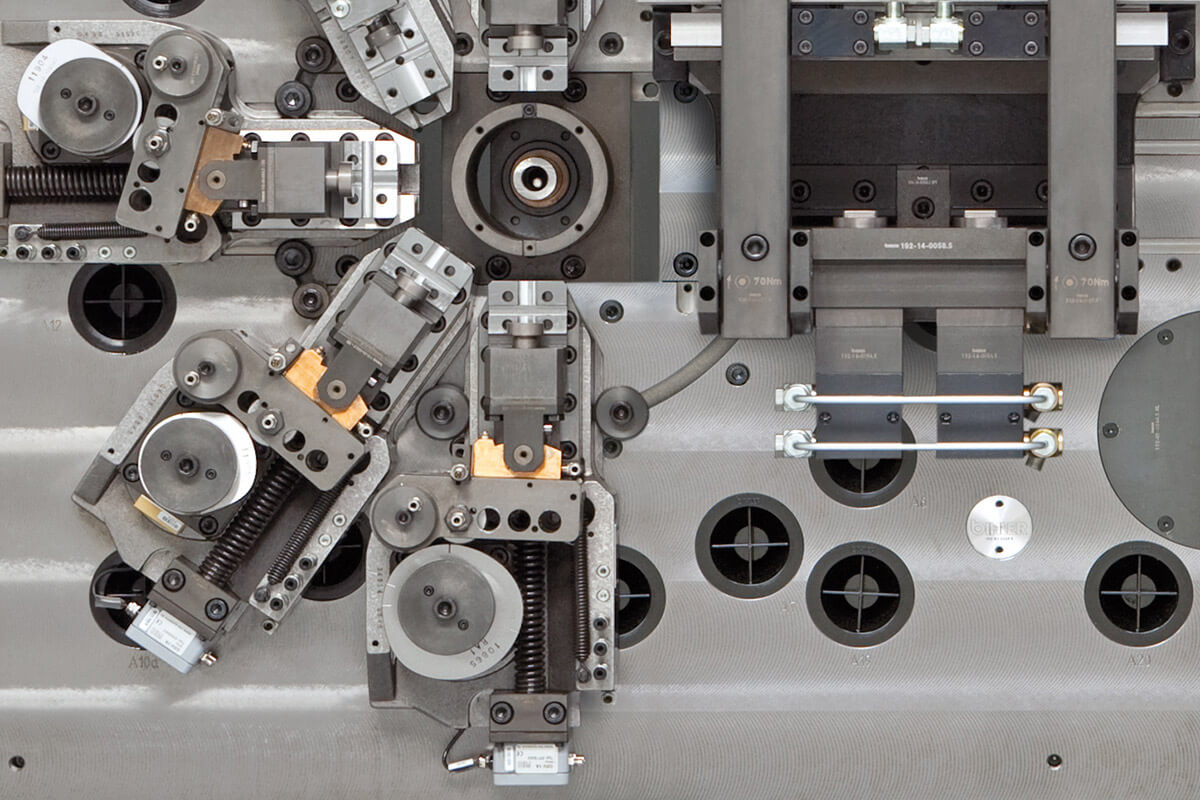

Tool clamping system provides minimum set-up time - VariControl VC 1 for simple operation and highest process reliability