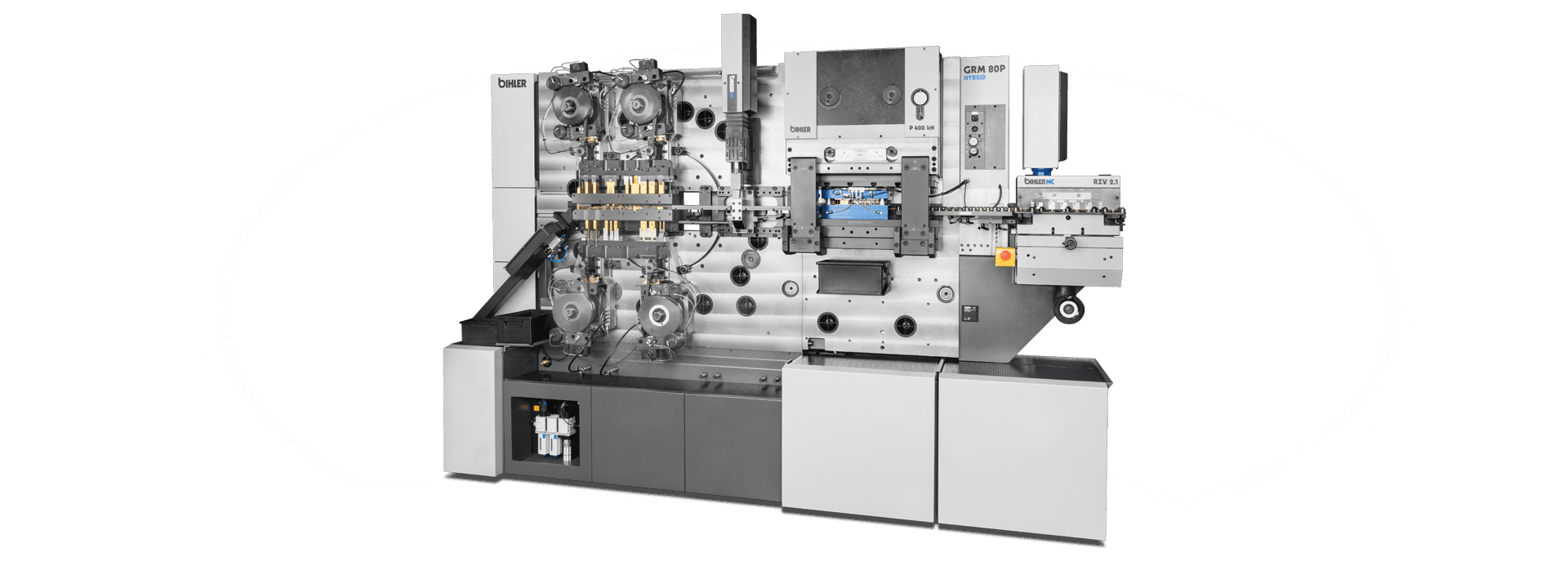

Powerful machining system for flexible mass production of larger stamped and formed parts as well as sub-assemblies

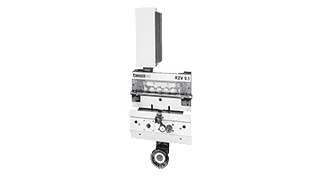

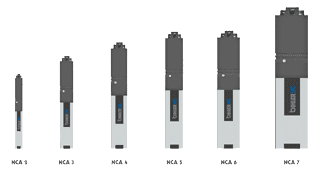

- Easy integration of servo axes for easier tooling solutions (high flexibility in case of variant diversity)

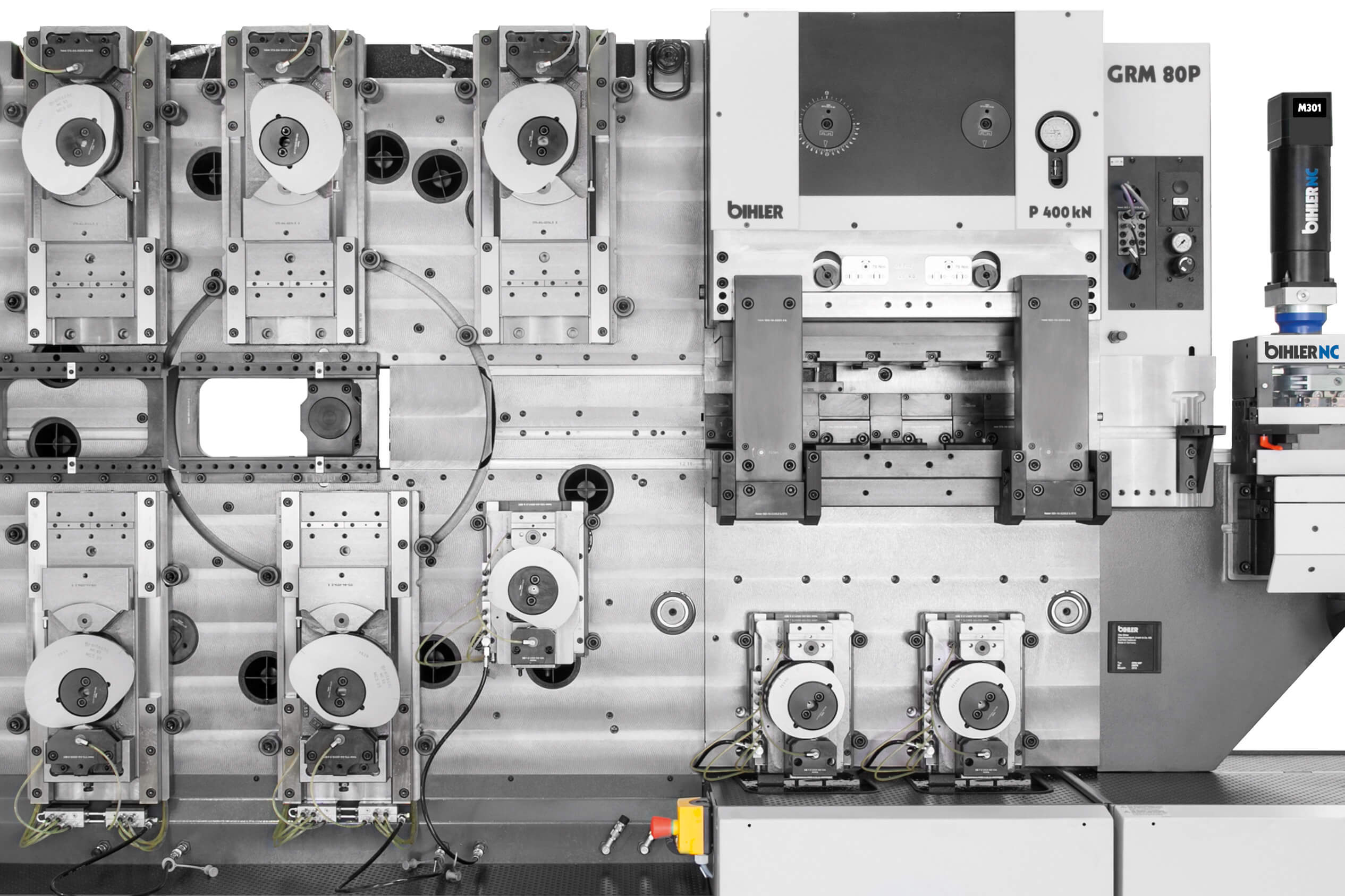

- Maximum processing room due to spatial separation of stamping and forming operations

- More than 2,100 mm (82”) machining path with linear tools

- Rigid 400 kN press for high-performance carbide tools

- Large center aperture for flexible integration of NC central mandrels (complete set-up from machine front side)

- Easy and secure operation with VariControl system