Advanced technology can complete manufacturing tasks where repeatable, precise results are essential. Automated manufacturing solutions utilize your specifications to produce consistent components within tight tolerances.

The Bihler Group of Companies has partnered with incredible manufacturers who lead their industries in:

We support innovation, efficiency and profitability for each of our partners, which is why we strive to create the most effective tools for your manufacturing needs. We can tailor our standard turnkey manufacturing automation equipment to equip them with the capabilities you need for specific production tasks.

As automation becomes more common and affordable in manufacturing, more brands have turned to Bihler to:

From agricultural resourcing to mining operations to medical technology, nearly every industry can find a use for custom manufacturing. The more specific your products, the better they can fulfill your clients’ needs. The first step toward developing a well-automated process is identifying the areas that would best benefit from enhanced manufacturing practices. Bihler systems are commonly utilized during these processes:

Our systems and optional modules are built with standard designs for compatibility with your existing operations. These solutions can also serve as a base for your new setup. Programmable modules allow you to change the equipment’s settings for specific tasks and further optimize manufacturing processes. These machines can produce even the most precise components, including dental molds, aerospace components and architectural elements.

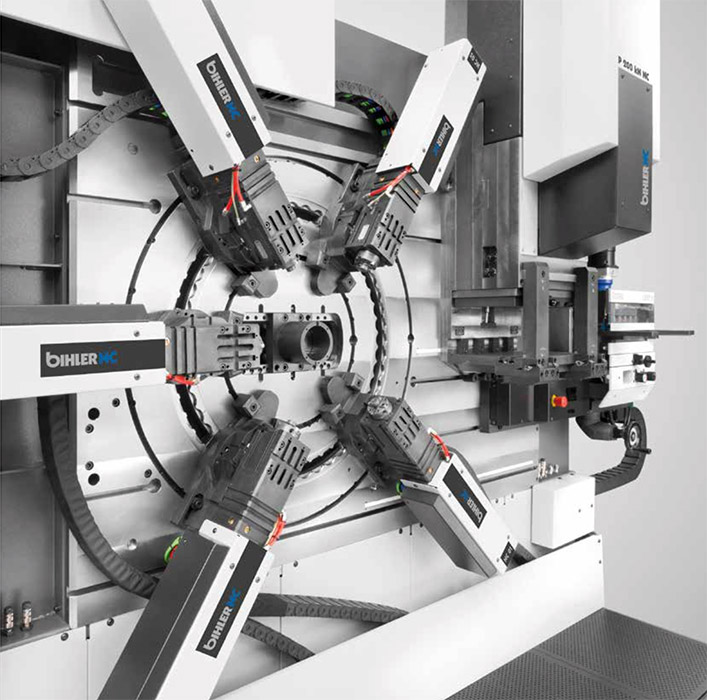

Bihler’s automation solutions optimize and advance production capabilities through flexible combinations of high-performance servo-driven processing modules. Industries around the world utilize custom manufacturing automation. From automotive construction to lab equipment design, businesses everywhere are becoming increasingly aware of the benefits of using automated systems. Whatever your industry, Bihler’s servo modules are capable of several practical applications, including:

Take advantage of the growing popularity of these systems and include them in your company’s production processes. Bihler servo modules offer maximum reliability, recording of measurement values, sensors and monitoring functions integrated into every process.

Individual servo process modules include material feeding, stamping, forming, rolling, welding, tapping, thread forming, screw insertion and assembly. These modules ensure your production line delivers precisely what you need for specific operations.

The programmable software allows for easy implementation of multi-directional movements for forming processes. Our all-in-one manufacturing system offers beneficial advantages to simplify production and reduce cost over standard sequential production processes.

With custom automation, our machines are fitted with tooling to achieve the exact specifications required to create your product. When you make the initial investment into Bihler technology, you’ll see ROI results almost immediately. We also provide in-house support services, so you can be sure that your machines are maintained and serviced regularly.

Bihler’s servo processing modules offer high-performance, customizable solutions for production, assembly and processing tasks. The user-friendly human-machine interface (HMI) enables process optimization through the intuitive input screens and quick parameterization of servo process modules.

The use of HMI provides another significant benefit to custom automation — safety. Mechanical machines can perform tasks and prevent human errors that might otherwise lead to safety problems throughout the assembly process. Custom machine automation is also helpful in reducing downtime and increasing production capacity.

Bihler’s innovative technology has revolutionized custom manufacturing capabilities in many industries, equipping our partners with advanced automation capabilities. We achieve customer satisfaction by providing the best in manufacturing technology and offering comprehensive consultations and on-site support.

Whether your operations are small or you are a large manufacturer scaling with demand, automated manufacturing can help you ensure precision and efficiency. Let us show you why Bihler is the best source for turnkey custom manufacturing automation equipment. Contact one of our technicians today to learn more or request your consultation.

Contact Us Today